Radar flowmeter, a device that uses the principle of electromagnetic wave reflection to measure fluid velocity, has been widely applied in the industrial field due to its non-contact measurement, high accuracy, and strong adaptability.

Today, we will explore the working principle of radar flowmeters and their applications in various scenarios, with the aim of providing a reference for technology selection and application in related fields.

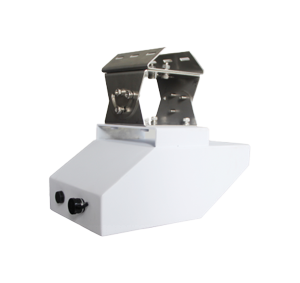

We need to clarify the core working mechanism of the radar flowmeter. It emits microwave signals at a certain frequency, which are reflected back by particles or bubbles in the fluid and then captured by a receiver.

By analyzing the time difference between the transmitted and received signals, combined with the known propagation speed of the signals, the fluid velocity can be calculated. This process is independent of temperature, pressure, or the conductivity of the fluid, allowing the radar flowmeter to maintain high measurement accuracy in variable industrial environments.

In the petrochemical industry, the application of radar flowmeters is crucial. This sector often involves flammable and explosive liquids or gases, posing safety hazards with traditional contact measurement devices. Radar flowmeters, on the other hand, can achieve long-distance non-contact measurement, effectively avoiding potential safety risks. For example, during crude oil transportation, radar flowmeters can monitor the flow rate in pipelines in real-time, ensuring transportation efficiency while providing data support for the safe operation of the pipelines.

In the water treatment field, radar flowmeters also demonstrate their unique advantages. Urban water supply systems, sewage treatment plants, and other such environments require accurate measurement of large volumes of water. Due to the presence of various impurities in the water and the wide range of flow variations, traditional flowmeters often struggle to maintain long-term stable performance. Radar flowmeters not only adapt to such working conditions but also allow for installation and maintenance without interrupting the water flow, significantly improving efficiency and measurement reliability.

Agricultural irrigation is another area where radar flowmeters excel. Efficient water management in agriculture is vital for improving water resource utilization. Radar flowmeters can be installed in channels or pipelines to precisely control irrigation water. Unlike other types of flowmeters, radar flowmeters are unaffected by water quality or deposits on the inner walls of pipes, ensuring long-term stable operation and contributing to the development of precision agriculture.

In addition, the application of radar flowmeters in hydrological monitoring should not be overlooked. Monitoring water levels and flow rates in rivers, lakes, and reservoirs is crucial for flood warning and water resource allocation. Radar flowmeters can be installed at key locations in these water bodies, continuously monitoring water level changes to provide real-time, accurate data support for hydrological analysis and decision-making.

Due to its unique working principle and wide range of applications, the radar flowmeter has become an indispensable measurement tool in many industrial sectors. From petrochemicals to water treatment, agricultural irrigation, and even hydrological monitoring, radar flowmeters consistently demonstrate excellent performance and reliability.

With continuous technological advancements and increasing application demands, radar flowmeters have tremendous potential for future development, particularly in improving measurement accuracy and expanding their scope of use.