In tank farm piping design, both metal flexible hoses and emergency shut-off valves (ESVs) are critical safety components. However, when they appear on the same pipeline, engineers often ask:

“Should the metal hose be installed upstream or downstream of the emergency shut-off valve?”

This article explains the correct arrangement from the perspectives of functional requirements, safety principles, and real accident cases.

1. Function of the Metal Hose

The primary purpose of a metal hose at the tank nozzle is to compensate for:

Differential settlement between the tank and the connected pipeline

Thermal expansion and contraction

Slight vibrations during operation

As long as the metal hose is positioned close enough to the tank nozzle, it can effectively absorb these displacements.

2. Function and Safety Requirements of the Emergency Shut-Off Valve

The ESV is designed to isolate the tank from external hazards during emergencies such as fire incidents. Its key safety principles include:

• No branch connections allowed between the ESV and the tank nozzle

Any additional openings increase the probability of leakage during emergencies.

• Minimize the number of flanged joints

Each flange is a potential leak source, particularly under fire exposure.

• The section between the ESV and the tank should represent the safest, most protected pipeline segment

This segment must maintain integrity long enough for emergency response and fire protection actions.

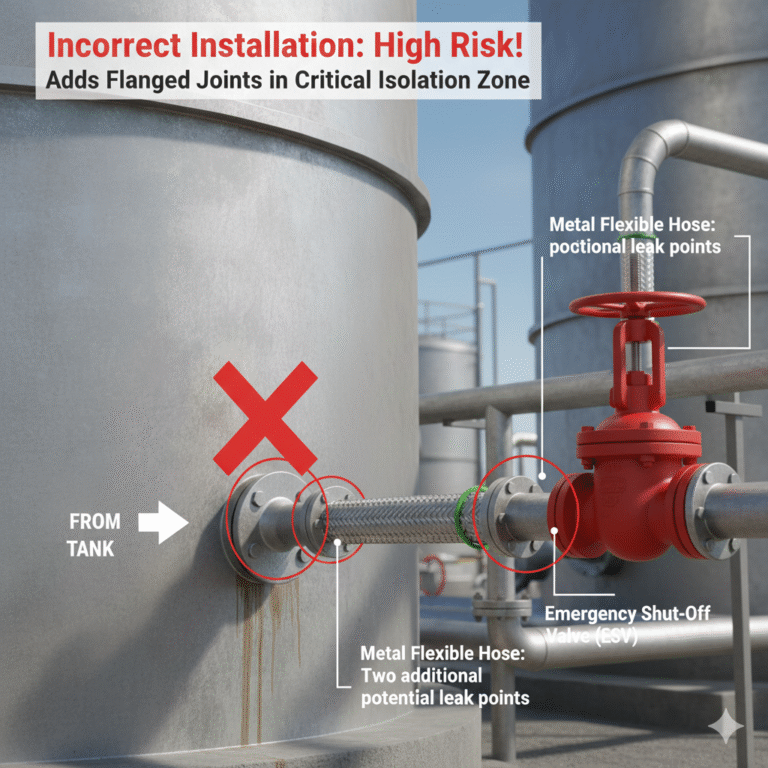

3. Why Metal Hoses Should Not Be Installed Before the ESV

Installing the metal hose upstream of the ESV introduces two serious safety risks.

3.1 It Adds Additional Flanged Joints (Potential Leak Sources)

Metal hoses are typically connected using two flanges, which means placing the hose before the ESV automatically increases the number of potential leakage points in the most critical isolation section.

This violates the safety principle of minimizing leak paths between the ESV and the tank.

3.2 Loss of Structural Integrity Under Fire Exposure

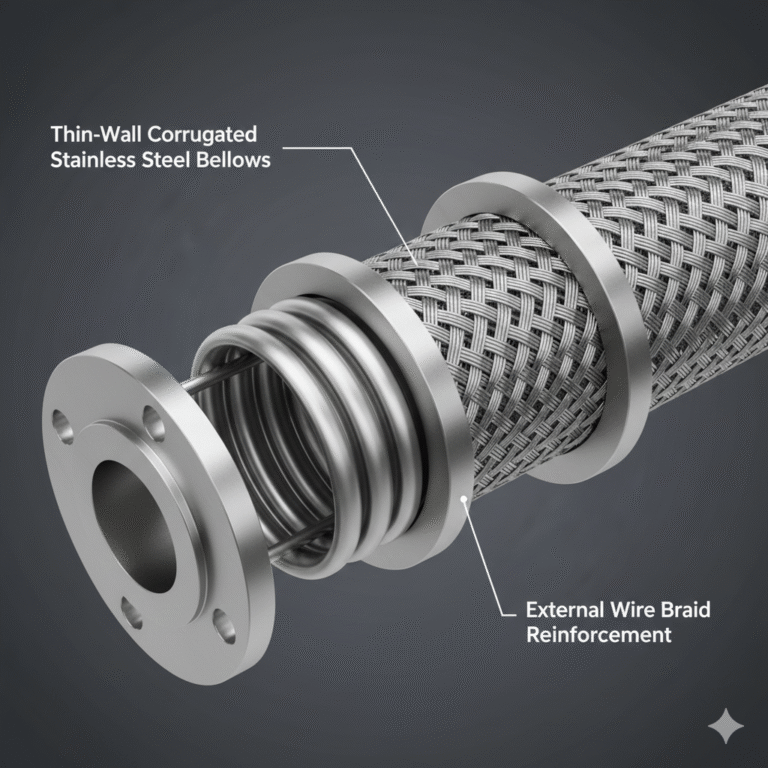

A typical metal hose consists of:

A thin-wall corrugated stainless-steel bellows

An external wire braid for pressure reinforcement

While sufficient under normal temperature, this structure cannot withstand prolonged fire exposure:

The strength of the bellows decreases rapidly at high temperature

The wire braid loses its load-bearing ability

The hose may rupture suddenly, resulting in uncontrolled product release

This failure mode is well-documented in fire-related incidents and is fundamentally incompatible with ESV protection philosophy.

4. Accident Case: Metal Hose Failure During Tank Fire

In a 2008 fire incident at a tank farm in Southwest China, the metal hose installed upstream of the emergency shut-off valve was directly exposed to radiant heat from a flowing-liquid fire.

The hose lost structural integrity and ruptured, causing additional fuel release and aggravating the fire escalation.

This incident demonstrates that metal hoses cannot be relied upon for fire endurance and must not be placed in the isolation zone protected by the ESV.

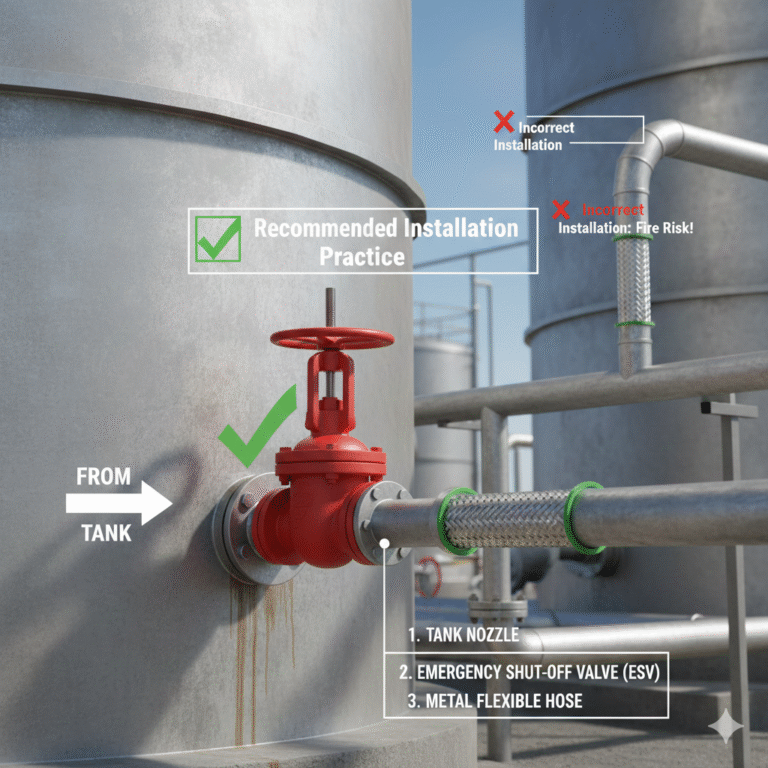

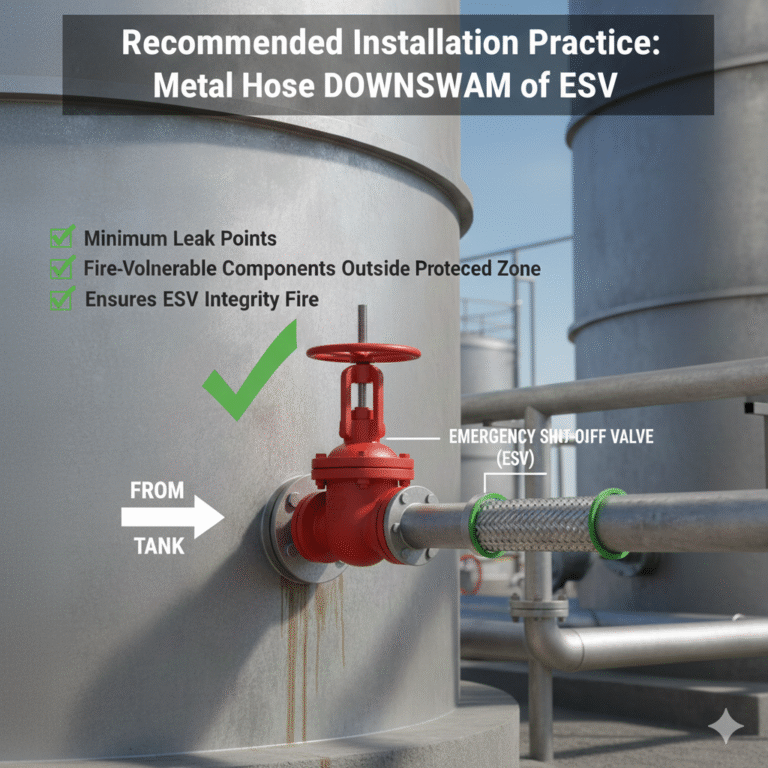

5. Recommended Installation Practice

Based on engineering principles and accident lessons:

✔ The metal hose should be installed after the emergency shut-off valve.

This arrangement ensures:

The isolation section between the tank and the ESV has minimum leak points

No fire-vulnerable components are placed in the protected zone

The integrity of the emergency shutdown function is maintained during fire scenarios

Conclusion

When both a metal flexible hose and an emergency shut-off valve are required on a tank pipeline, the metal hose must be installed downstream of the ESV. This configuration meets safety design principles and prevents early hose failure during fire exposure.