Radar level transmitters have become one of the most reliable technologies for liquid and solid level measurement. With advantages such as non-contact measurement, high accuracy, strong anti-interference capability, minimal maintenance, and long service life, radar instruments are now widely used across process industries.

Among various radar frequencies—6GHz, 26GHz, 80GHz, and even 120GHz—the 26GHz and 80GHz models are the most commonly compared. Although both belong to the microwave radar family, their operating principles and performance differ significantly due to frequency, wavelength, beam angle, and antenna design.

This article provides a clear, practical comparison to help you select the right type for your application.

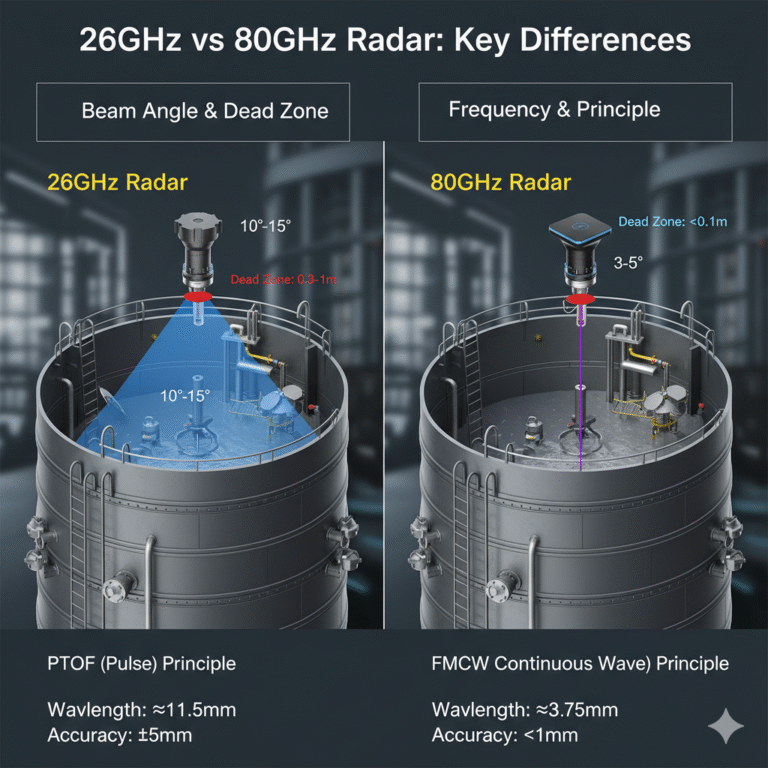

1. Frequency & Wavelength: The Foundational Difference

Microwaves span from 300MHz to 300GHz, with wavelengths from 1m to 1mm. Based on frequency, they are divided into:

Decimetre waves: 300MHz–3GHz

Centimetre waves: 3–30GHz

Millimetre waves: 30–300GHz

Frequency and wavelength are inversely related:

c = λf (speed of light = wavelength × frequency).

26GHz Radar

Operating frequency: 24–26GHz

Wavelength: ≈11.5 mm

Falls within the centimetre-wave band

80GHz Radar

Operating frequency: 78–82GHz

Wavelength: ≈3.75 mm

Falls within the millimetre-wave band

Shorter wavelength = better focusing ability and higher resolution, which is a key reason why 80GHz performs better in complex environments.

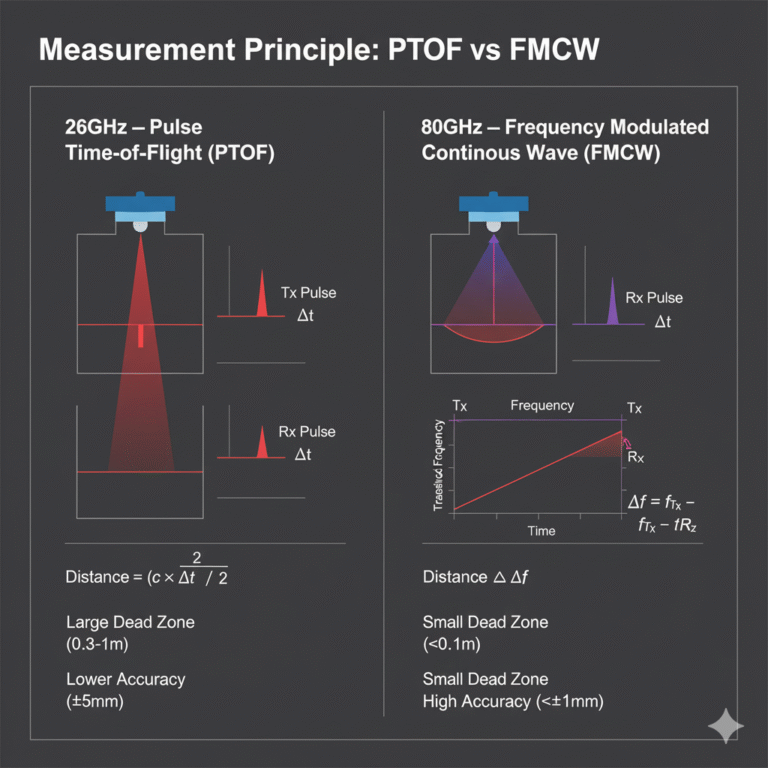

2. Measurement Principle: PTOF vs FMCW

26GHz — Pulse Time-of-Flight (PTOF)

26GHz radars typically use pulse radar technology.

The transmitter emits very short high-frequency pulses; the reflected signal is received after bouncing off the surface. The instrument calculates distance based on:

Distance = (c × Δt) / 2

Features:

Mature technology

Lower cost

Limited by pulse width → larger dead zone (typically 0.3–1m)

Lower resolution (≈±5 mm)

Suitable for applications where extremely high precision is not required.

80GHz — Frequency Modulated Continuous Wave (FMCW)

80GHz radars operate on FMCW technology, emitting continuous waves whose frequency changes linearly over time. When the reflected wave returns, its frequency differs from the transmitted wave.

The frequency difference (Δf) is proportional to distance:

Δf ∝ Distance

Advantages:

Very small dead zone (often < 0.1m)

High resolution (≈±1 mm)

Strong anti-interference capability

Excellent in near-range or complex conditions

FMCW radar is now the mainstream solution in high-precision and advanced process applications.

3. Beam Angle: The Key to Performance in Complex Tanks

Beam angle determines the radar’s ability to avoid disturbances such as tank walls, coils, agitators, and ladders.

Typical Beam Angles

26GHz: 10°–15°

80GHz: 3°–5°

This gives 80GHz a major advantage:

Narrow beam = better focusing

Minimal reflection from obstacles

Ideal for narrow tanks, small nozzles, or crowded internal structures

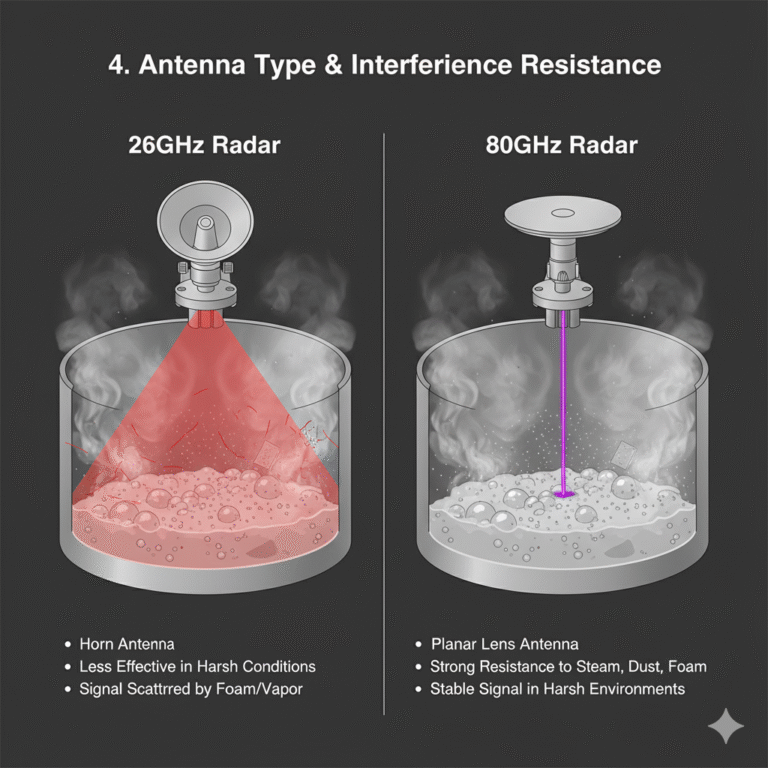

4. Antenna Type & Interference Resistance

80GHz Radar

Often uses planar microstrip or lens antennas, which provide:

Strong resistance to steam, dust, foam, condensation

Stable signals even in harsh environments

Superior performance in agitated tanks, where swirling surfaces or foam are common

26GHz Radar

Mostly uses horn antennas, which:

Are robust and proven

Perform well in standard conditions

Are less effective in environments with heavy dust, strong vapor, turbulence, or obstructions

5. How to Select: 26GHz or 80GHz?

Situations where 80GHz is the Best Choice

✔ Tanks with agitators, coils, ladders, or heating pipes

✔ Small tanks / vessels with limited space (nozzle < 1m)

✔ Mediums with foam, vapor, condensation, or low dielectric constant

✔ Applications requiring high precision (batching, custody transfer)

✔ When installation length is limited (short nozzles)

✔ Solid measurement — powders, pellets, grains

80GHz provides the highest reliability in challenging environments.

Situations where 26GHz is More Suitable

✔ Large standard storage tanks (water, wastewater, crude oil, chemicals)

✔ Budgets are tight and accuracy requirements are moderate

✔ Mediums with good reflection characteristics (εr high)

✔ Applications without internal obstacles or disturbances

26GHz remains cost-effective and stable for straightforward applications.

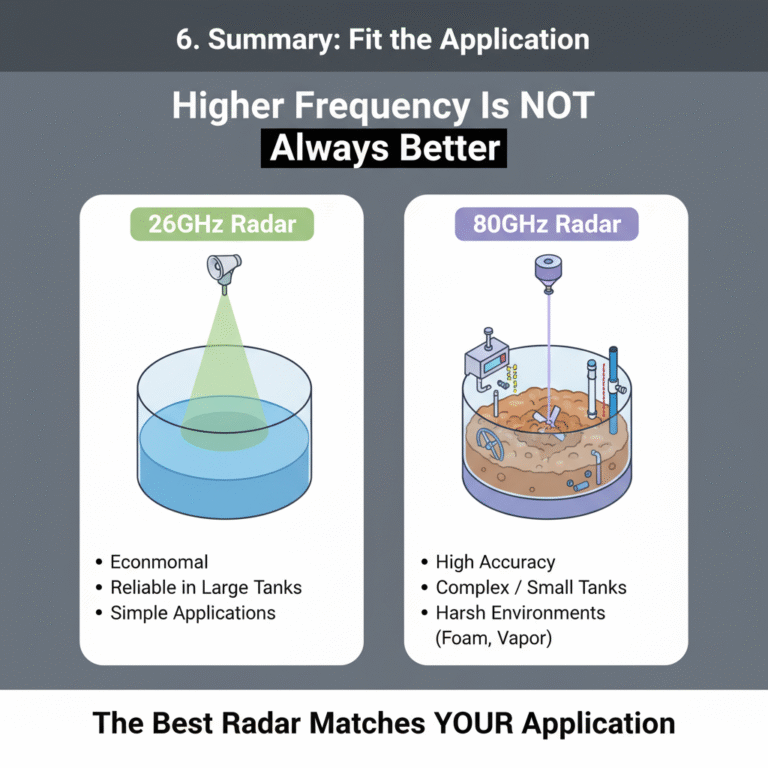

6. Summary: Higher Frequency Is Not Always Better — Fit the Application

80GHz radar offers:

Smaller beam angle

Higher accuracy

Smaller dead zone

Better performance in complex, small, or harsh environments

While 26GHz remains:

Mature

Economical

Reliable in simple and large-tank applications

The correct choice depends on process complexity, accuracy requirements, installation conditions, medium properties, and project budget.

The best radar is the one that matches your application—not necessarily the highest frequency.