How Pressure & Temperature Transmitters Win the Battle in Fine Chemical Production**

In the world of fine chemicals and petroleum additives, every drop of product represents the highest level of industrial precision. Here, “almost correct” does not exist—even the slightest deviation in temperature, pressure or concentration can scrap an entire batch, damage equipment, or trigger serious safety incidents.

In these demanding environments, pressure and temperature transmitters—a pair of instruments often overlooked—play a decisive role. Working together, they form the most critical sensory system for process control and plant safety.

This article takes you deep into how this combination becomes the hidden champion behind quality, stability, and operational excellence.

1. The Harsh Battleground:

Why These Instruments Are the “Sensory Nerves” of Fine Chemical Processes**

Fine chemical and additive production frequently involves:

High temperature and high pressure

Corrosive, viscous, toxic or flammable media

Highly sensitive reactions

Strict regulatory and safety requirements

Chemical reactions such as polymerization, synthesis, and catalysis demand extremely tight control. A minor fluctuation in temperature or pressure can alter reaction pathways, impact molecular weight distribution, or even push the reaction out of control.

In such environments:

Relying on a single temperature or pressure measurement is insufficient.

Only the combined monitoring of both parameters can create a complete, accurate picture of process conditions.

This combination becomes the backbone of DCS automation and SIS (Safety Instrumented Systems), acting as the plant’s most reliable “sensory nerves.”

2. Where the Dual System Shines:

Critical Applications Across the Plant**

1) Reactors — the “Brain” of the Process and the First Line of Defense

The reactor is the most demanding measurement location.

Process Control:

Precise temperature and pressure control ensures the reaction proceeds at the correct rate, determining:

Conversion efficiency

Product consistency

Polymer chain distribution

Reaction selectivity

Safety Protection:

When any abnormal rise in temperature or pressure occurs, the dual-transmitter setup sends instant warnings to trigger:

Emergency cooling

Venting

Shutdown interlocks

This prevents runaway reactions and ensures plant safety.

2) Distillation Columns — the Gatekeepers of Product Purity

For fine chemical separation:

The temperature-pressure relationship at the reboiler and condenser determines separation performance.

Multi-point measurement allows for:

Higher purity

Better energy efficiency

Optimized heat integration

Accurate temperature and pressure readings are essential for yield improvement and cost reduction.

3) Storage Tanks & Pipelines — Continuous Surveillance for Safety

Storage Tanks:

Real-time monitoring prevents both overpressure and vacuum collapse, protecting tank integrity.

Pipelines:

Pressure drop helps diagnose blockages in viscous materials.

Unusual pressure-flow combinations can indicate leaks at an early stage.

The dual measurement system ensures safe operation across the entire plant.

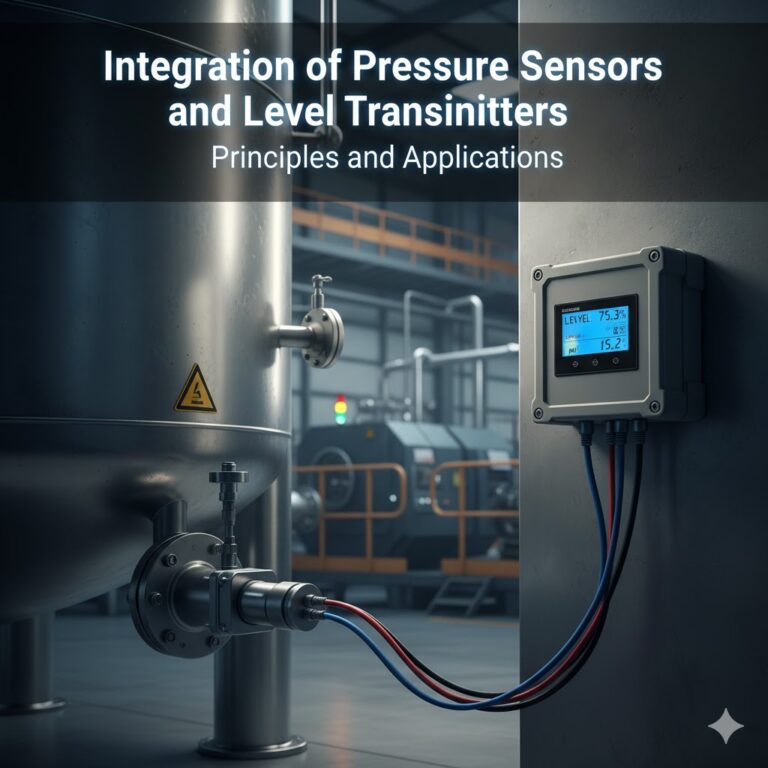

3. The Power of Integration:

Why 1 + 1 > 2

1) Accurate Density Compensation

For steam flow, gas flow, or liquid level in pressurized tanks:

Temperature changes density

Pressure changes density

Accurate measurement requires both parameters

By using real-time density correction, the system delivers far more accurate and stable results.

2) Intelligent Process Diagnostics

The system performs cross-checking like a seasoned operator:

In boiling conditions, temperature and pressure must match vapor–liquid equilibrium.

When one reading deviates while the other remains normal, the system can detect:

Sensor drift

Calibration issues

Instrument blockage

This supports predictive maintenance and improves reliability.

3) Foundation for Advanced Process Control (APC)

Modern APC algorithms require multi-variable inputs.

The temperature–pressure pair enables:

Predictive modeling

Optimized valve coordination

Tighter control loops

Lower energy consumption

It is the foundation for modern smart manufacturing.

4) One-Port Integration: A Growing Industry Trend

More plants are adopting integrated temperature–pressure assemblies, offering:

Fewer process penetrations

Lower leakage risk

Compact installation in tight spaces

Simplified maintenance

This is especially advantageous in reactors and high-pressure systems.

4. How to Choose the Right Instruments:

Golden Rules for Selection and Installation**

Choosing the right transmitters is vital for stability and safety.

1) Material Compatibility

For corrosive, sticky, or toxic media:

316L stainless steel

Hastelloy C276

Tantalum

PTFE-lined wetted parts

Flush diaphragm pressure transmitters for viscous applications

2) Accuracy & Long-Term Stability

High-value chemical production requires high accuracy, excellent repeatability, and minimal drift.

3) Safety Certifications

In hazardous areas, compliance with:

Ex d IIC T6 Gb

IECEx / ATEX

is mandatory.

4) Smart Communication

Transmitters supporting:

HART

Profibus PA

Modbus

Foundation Fieldbus

allow remote configuration, diagnostics, and integration with predictive maintenance strategies.

Conclusion

In today’s fine chemical and petroleum additive industries, pressure and temperature transmitters do far more than conventional measurement.

They have become:

Eyes of the process

Shields of safety

Engines of efficiency

Investing in a reliable, accurate, and intelligently integrated measurement solution is one of the most effective ways to strengthen:

Production stability

Safety performance

Product quality

Overall competitiveness