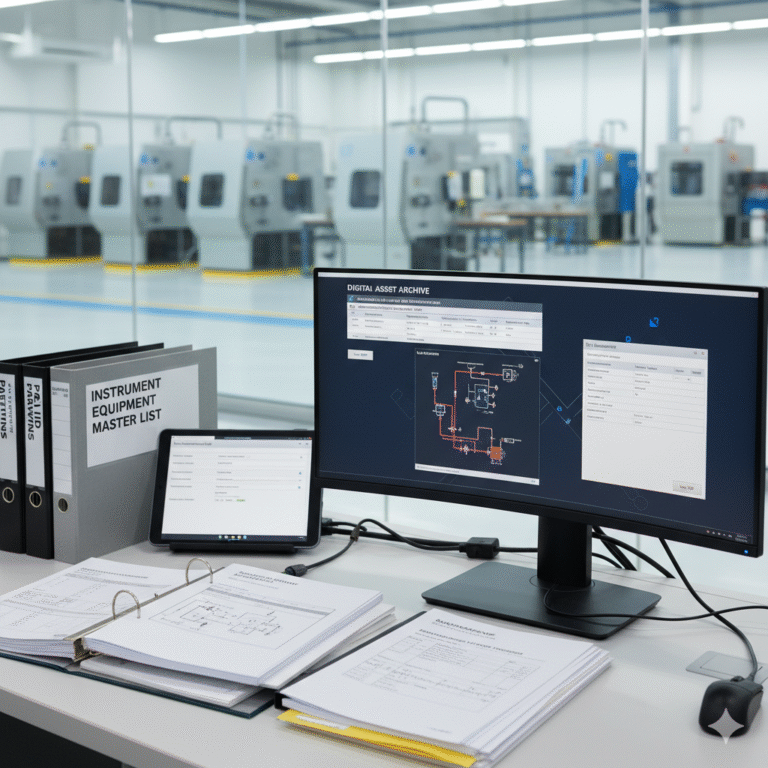

1. Documentation and Records

Each workshop or unit instrument maintenance team shall establish and maintain the following technical documents and records:

1.1 Instrument equipment master list and digital archive.

1.2 Instrument summary list for each process unit.

1.3 Instrument maintenance and overhaul operating procedures.

1.4 Technical manuals and operation instructions for all installed instruments.

1.5 Maintenance, calibration sheets and calibration records for instruments and accessories.

1.6 Data sheets for throttling elements and control valve sizing calculations.

1.7 Valid certificates for standard calibration instruments.

1.8 Complete instrumentation control system drawings, including:

Equipment list

Instrument installation drawings

Loop diagrams

Wiring diagrams

Interlock logic diagrams

Interlock function charts

P&IDs with control points

Design, installation and handover documents

1.9 A/B class interlock, DCS, UPS, PLC and Industrial PC inventory list.

1.10 Shift handover logs and inspection patrol records.

1.11 Static sealing point register for each unit.

1.12 Monthly and quarterly instrument technical condition reports.

2. Instrument Renewal and Disposal

Requests for renewal or scrapping of instruments must be submitted by the maintenance team, reviewed by the Equipment Department, and approved by relevant company authority.

3. Addition or Removal of Instruments

Any addition, removal, or modification of instrument loops must be applied for by the user unit and approved by the Production and Equipment Department before execution.

4. Fixed Assets

Instrument equipment classified as fixed assets shall be managed according to the company’s fixed asset management system.

5. Instrument Transfer

Transfer of instrument equipment must be approved by the Production and Equipment Department. Transfer of DCS/PLC/ESD spare parts must additionally be filed for record.

6. Reporting Requirements

Each maintenance team shall submit quarterly automation status reports, including:

a) Instrument equipment availability performance indicators.

b) Analysis report of any unit shutdowns caused by instrument failures.

c) Interlock activation/deactivation status report.

7. Annual Summary

An annual inventory and operational performance summary of automation instruments shall be completed at year-end.

8. Major Failures

Major instrument faults affecting key unit operation shall be addressed immediately and reported to the Production and Equipment Department and relevant management.

9. Classification of Instruments

Classification of A/B/C grade instruments shall be implemented according to the company’s metering and instrument classification standards.

10. Interlock System Management

Safety interlock system management shall comply with the company’s safety interlock system management regulations.

11. DCS System Management

DCS system operation and maintenance shall comply with the company’s DCS management procedures.

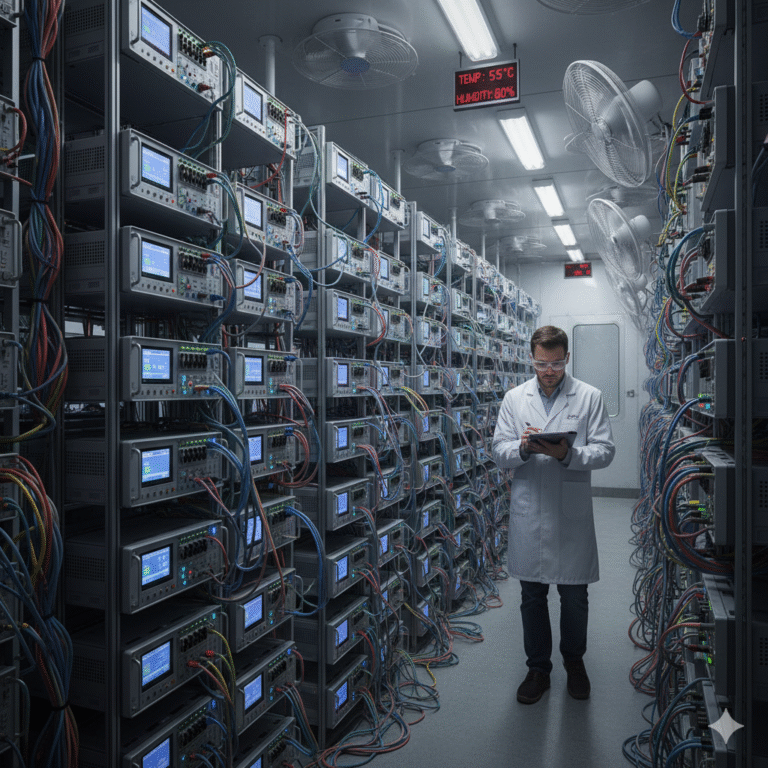

Instrument Maintenance and Overhaul Procedure

1. Maintenance Categories

Instrument maintenance is categorized into major overhaul, medium overhaul, and minor overhaul:

a) Major Overhaul:

Complete disassembly, cleaning, repair or replacement of major components; full performance testing according to factory inspection standards.

b) Medium Overhaul:

Partial disassembly, repair or replacement of key components; calibration of primary performance parameters.

c) Minor Overhaul:

Routine cleaning, adjustments, troubleshooting and minor repair.

2. Responsibilities

Major and medium overhauls are performed by the instrument maintenance unit; minor repairs are conducted by on-site maintenance personnel.

3. Preparation Work

Before shutdown maintenance, the following must be confirmed and prepared at least one month in advance:

Drawings

Spare parts and consumables

Materials and tools

Personnel allocation

Safety measures

4. Additional Work

Any additional overhaul work must be approved by the Production Operation Department before execution.

5. Acceptance

Critical overhaul items (e.g., interlock verification, DCS loop testing) shall be jointly inspected by the Equipment Department and related responsible personnel. General items may be accepted by the maintenance team.

6. Quality Assurance

Comprehensive quality management shall be implemented throughout the maintenance process, establishing and maintaining a quality assurance system.

7. Safety Requirements

All maintenance activities must follow safety regulations and HSE requirements to ensure safe and orderly operation.

8. Documentation

Inspection, calibration, functional testing, and pressure test records must be completed and archived.

9. Overhaul Summary

After completion of major overhaul, a summary report shall be prepared and submitted to relevant departments.

10. Procedure Compliance

All instrument overhaul work must strictly comply with the approved maintenance procedures.