Most traditional flowmeters (such as electromagnetic, vortex, and turbine meters) require the pipe to be completely filled with fluid. In partially full pipe conditions, where gas (typically air) exists above the liquid, it can significantly affect the measurement accuracy and even damage the instruments.

Below are some flowmeters specifically designed for partially full pipes or open channel conditions. The selection can be made based on the specific scenario:

1. Ultrasonic Level/Flow Meter

This is currently the most commonly used and mainstream solution for measuring flow in partially filled pipes.

Measurement Principle:

The sensor is installed at the top of the pipe and uses ultrasonic pulses to measure the liquid level. The internal microprocessor calculates the fluid’s cross-sectional area based on the pre-set pipe dimensions (circular, rectangular, etc.) and liquid height. By combining the pre-set flow rate (for fixed weirs/flumes) or actual flow velocity from multi-channel measurements, it calculates both instantaneous and cumulative flow.Advantages:

Non-contact measurement: The sensor does not come into direct contact with the fluid, minimizing wear, corrosion, and contamination, leading to very low maintenance.

Wide applicability: Suitable for various pipe shapes (circular, square, trapezoidal) and open channels.

Easy installation: No need to cut the pipe. It can be installed by drilling a hole in the pipe top or mounted directly above the channel.

High measurement accuracy.

Disadvantages:

Sensitive to steam, foam, suspended solids, or scaling on the pipe walls.

For irregularly shaped pipes, precise calibration is required.

Typical Applications:

Municipal drainage, wastewater treatment plants, industrial wastewater discharge, stormwater networks, etc.

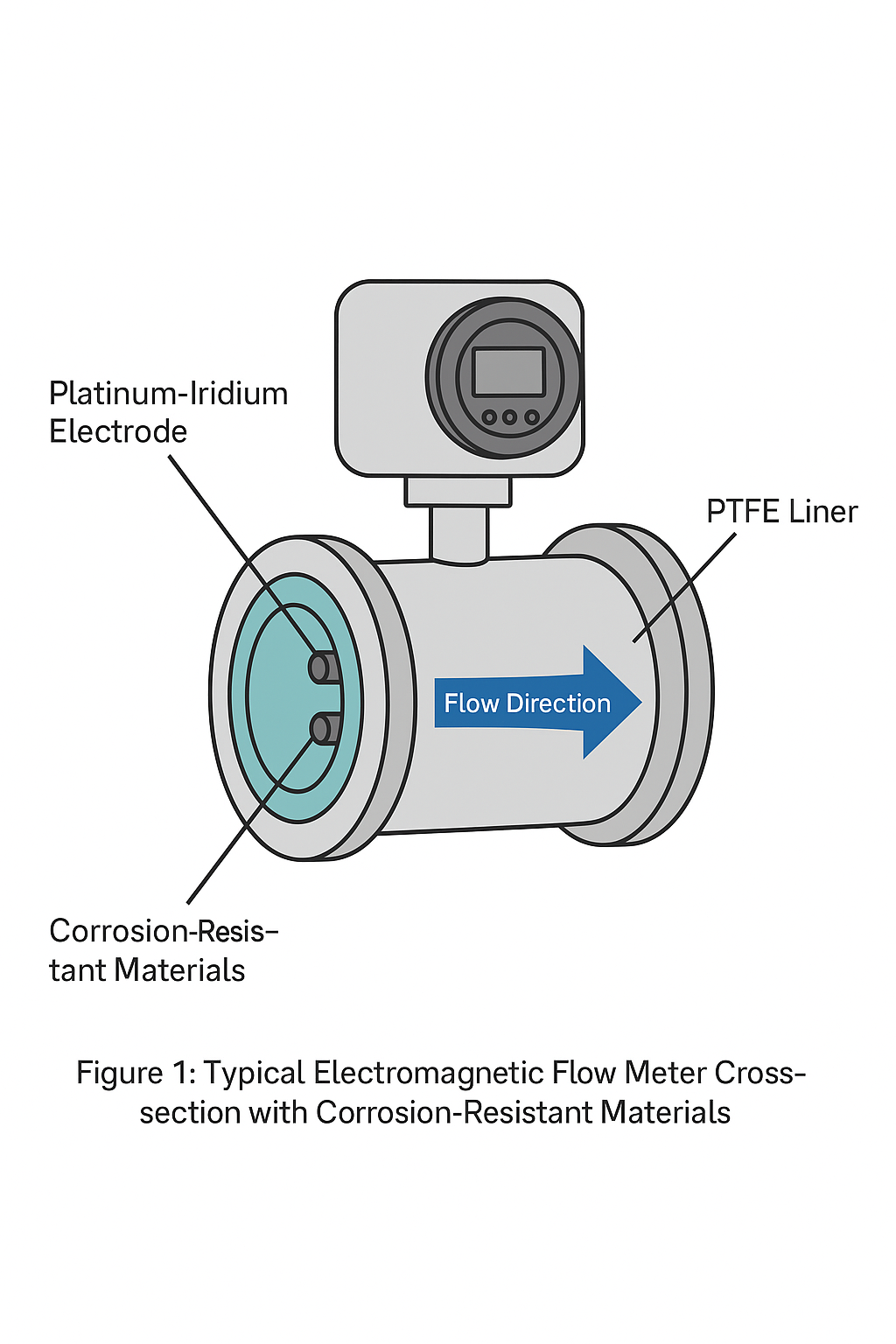

2. Electromagnetic Flow Meter (Specially Designed for Partial Pipe Measurement)

Note: Standard electromagnetic flowmeters should not be used in partially full pipe conditions as this can result in inaccurate measurements and potential damage to the electrodes. However, there are special electromagnetic flowmeters designed to handle partial pipe flow.

Measurement Principle:

Similar to the principle of standard electromagnetic flowmeters (Faraday’s electromagnetic induction law), these meters use specially designed electrodes and signal processing technology. For example, they use three-electrode or four-electrode configurations to ensure stable measurement even with fluctuating liquid levels.Advantages:

High accuracy and excellent repeatability.

Unaffected by fluid density, viscosity, temperature, or pressure.

Suitable for measuring corrosive fluids and slurries with solids.

Disadvantages:

Higher cost compared to ultrasonic level/flow meters.

Installation requires cutting the pipe, making it more complex.

Requires the fluid to have a minimum electrical conductivity.

Typical Applications:

Industrial process control requiring high precision, wastewater treatment, etc.

3. Flume/Venturi Flume + Level Meter

This is a classic measurement method, especially suitable for open channels and large diameter pipes.

Measurement Principle:

A flow restriction device (such as a flume or a Venturi flume) is installed in the channel or pipe. As fluid flows through the restriction, the liquid level increases at a specific location (usually at the throat). There is a fixed mathematical relationship between this liquid height and the flow rate. By measuring the liquid level, the flow can be accurately calculated. The level sensor used is typically an ultrasonic or pressure-based level meter.Advantages:

Simple structure, durable, and low maintenance.

Less prone to clogging when measuring fluids with high suspended solids, such as slurry.

Wide measurement range.

Disadvantages:

Requires a large installation space and strict straight pipe section requirements.

Some head loss occurs.

Accuracy depends on the precision of the flume and the level measurement.

Typical Applications:

Agricultural irrigation, urban flood control, inlet and outlet flow measurements in wastewater treatment plants.

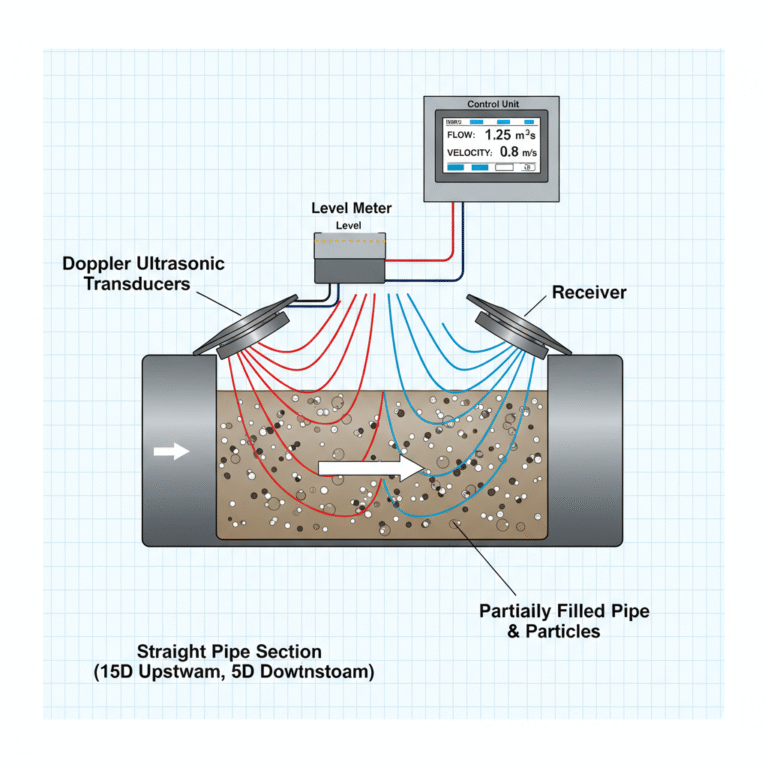

4. Doppler Ultrasonic Flow Meter

While primarily used in fully filled pipes, this meter can also be used in certain partial pipe conditions.

Measurement Principle:

This method utilizes the Doppler frequency shift effect caused by ultrasonic waves encountering particles or bubbles in the fluid. The velocity of the particles or bubbles is measured, which helps determine the flow velocity. However, this method cannot directly measure the cross-sectional area and must be used in conjunction with a level meter to calculate flow.Suitable Conditions:

When the pipe is not fully filled, but the fluid contains enough reflective particles (such as bubbles or solid particles), the Doppler ultrasonic flowmeter can be used. The meter works by using the sound signals reflected by bubbles and particles in the fluid, so if the fluid doesn’t contain bubbles or particles, it won’t work. Typically, fluids with at least 30% suspended solids are suitable for measurement.Advantages:

Can measure complex media such as slurries, oil-water mixtures, and fluids with suspended solids.

No zero-point drift. When the fluid is at rest, no Doppler frequency shift occurs, so there is no zero-point drift in the control unit display.

Disadvantages:

Measurement accuracy is significantly affected by the number and distribution of reflective particles in the fluid.

Requires a stable flow in a straight section of pipe (minimum upstream length of 15d and downstream length of 5d).

Installation position is crucial.

Summary and Selection Advice

How to choose?

Primary Consideration: The ultrasonic level/flow meter is the most versatile choice for partially full pipe flow measurement, offering the best balance of cost, installation convenience, and applicability.

If Precision is Critical and Budget Allows: Consider a specialized electromagnetic flow meter designed for partial pipe flow measurement.

For Large Open Channels or Flumes with High Solid Content in Fluid: A Venturi flume is a reliable and cost-effective choice.

Avoid Using: Turbine, vortex, or orifice meters, as they are designed for full pipe flow and cannot operate correctly in partial pipe conditions.