The core logic behind the source calibration method is to trace the origin of data (such as original collection devices, reference documents, or authoritative data sources) and verify its accuracy by comparing it with a “source standard.” This method is especially suitable for data types where the origin is traceable and there is an objective “reference basis” (such as standard equipment, authoritative documents, or physical true values).

In industrial scenarios (e.g., electrical instrumentation, automation, and control systems) and general business contexts, the typical data types that benefit from source calibration can be divided into four categories, explained below:

1. Dynamic Acquisition Data (Core Application in Industrial Scenarios)

This type of data is generated in real-time or periodically by sensors, instruments, and acquisition devices. The accuracy of the data directly depends on the precision of the acquisition device and needs to be validated through the calibration of the “source of acquisition” using standard tools. This is one of the most common uses of the source calibration method in industrial electrical instrumentation and automation systems.

Typical Data Examples:

Electrical data (current, voltage, power) from current sensors and voltage transmitters.

Process data (temperature, pressure, flow) from thermocouples, pressure transmitters, and flow meters.

Equipment operational data (e.g., motor speed, frequency from variable frequency drives) obtained from speed sensors and PLC modules.

Calibration Logic: Standard-grade equipment is used to output known reference signals or physical quantities, which are compared with the measurements from the acquisition device. The deviation is assessed to see if it falls within the allowable range (e.g., industrial-grade sensors typically require deviation ≤ ±0.5% FS, precision-grade sensors ≤ ±0.1% FS).

Example: When verifying the data from a workshop temperature sensor, use a certified standard thermometer (accuracy ±0.05°C) placed at the same monitoring point. Once the readings stabilize, compare the sensor’s reading with the standard thermometer’s value. If the deviation exceeds ±0.5°C, the sensor’s data is deemed inaccurate and requires recalibration or replacement.

2. Physical Parameters and Equipment Attribute Data

This data describes the inherent attributes or static parameters of physical entities (e.g., equipment, materials, or facilities). The source of this data is usually original documents such as factory certificates, design drawings, and authoritative test reports. It needs to be validated by tracing these source documents to ensure the correct data entry/storage.

Typical Data Examples:

Equipment ratings (e.g., rated power of motors, rated capacity of transformers, rated current of circuit breakers).

Material property data (e.g., purity, density, flashpoint of chemicals, sourced from supplier certificates).

Facility structural parameters (e.g., pipeline diameters, valve nominal pressures, sourced from engineering design drawings).

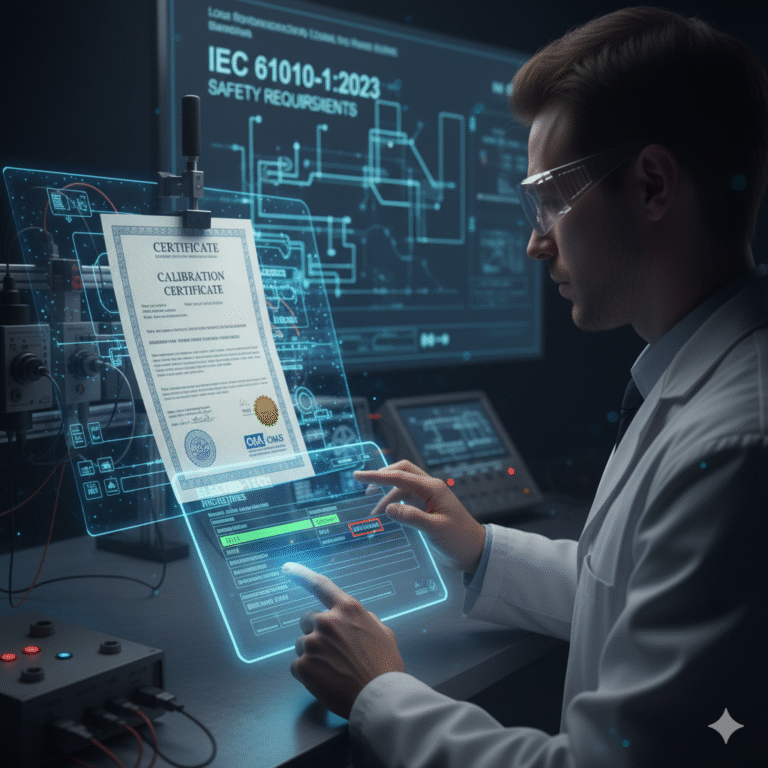

Calibration Logic: Existing data (e.g., system logs, database records) is compared against the original values in the “source documents.” If inconsistencies are found, the data is corrected to match the source document (after ensuring the validity of the source document itself, such as factory certificates bearing the manufacturer’s seal or test reports with CMA/CNAS certification).

Example: When verifying the “rated voltage” of a high-voltage switchgear in an electrical instrumentation system, consult the equipment’s factory certificate (source document) that lists the voltage as 10kV. Compare it with the system’s logbook entry of “10kV.” If the entry reads “6kV,” the data is deemed incorrect and needs to be corrected.

3. Reference and Standard Data

This type of data serves as a “standard value” for reference, and its accuracy directly affects the validation of other data. It must be calibrated using a higher-level authoritative source to ensure its integrity as a reference.

Typical Data Examples:

Measurement standards (e.g., “standard resistance values,” “standard voltage source parameters” from calibration certificates issued by national measurement institutes).

Industry or national standards (e.g., electrical safety voltage standards, SIL levels from national or international standards such as GB/T or IEC).

Process benchmark parameters (e.g., “standard temperature curves” for a specific product or “tolerances for qualified product dimensions” from company technical documents).

Calibration Logic: Periodically (e.g., annually, according to regulatory requirements), the existing reference data is synchronized with “authoritative sources.” If the authoritative standards are revised (e.g., national standards are updated), the existing reference data must be recalibrated immediately to prevent future data validation failures.

Example: A standard current signal generator used in a company’s laboratory to calibrate sensors needs to be sent to a national metrology institute annually for testing and recalibration. If the certificate shows that the deviation at the 20mA setting has increased from ±0.01mA to ±0.03mA, the laboratory’s “standard signal parameter table” must be updated, and the new deviation range must be used for future calibrations.

4. Traceable Manual Entry Data

This data is manually entered into systems (e.g., maintenance records, inspection data). Although it is not automatically collected by equipment, it has a clear “entry source” (such as paper records or onsite observations) and must be validated by tracing the “original basis” of the entry.

Typical Data Examples:

Equipment maintenance records (e.g., “motor bearing replacement date,” sourced from maintenance work orders).

Onsite inspection data (e.g., “seal check results for distribution cabinet doors,” sourced from inspection checklists).

Material inventory data (e.g., “cable lengths,” sourced from supplier delivery notes or onsite measurement records).

Calibration Logic: Randomly select manual entry data from the system and cross-check it with the “original source document” (e.g., paper work orders, signed checklists). The focus is to verify the accuracy of key information (e.g., dates, values, result judgments) to avoid data distortion caused by manual entry errors (e.g., omission, incorrect entry, or legibility issues).

Example: When verifying the “maintenance completion time” in an electrical instrumentation system’s “variable frequency drive maintenance record,” consult the corresponding paper work order (source document). If the work order confirms the completion time as “2024-05-10 15:30,” the data is accurate. If the work order shows “2024-05-11 10:00,” the entry date is incorrect and needs to be corrected.

Core Characteristics of the Source Calibration Method

To determine whether a certain type of data is suitable for the source calibration method, two key criteria must be met:

Traceability of the Source: There must be a clear, unchangeable “original basis” (such as standard equipment, authoritative documents, or onsite certificates).

Comparability of the Reference: The source basis must provide an “objective standard value” (e.g., standard signals, factory parameters, regulatory requirements) that can be compared directly with existing data.

If data does not have a clear source (e.g., unstructured text descriptions or subjective evaluations), or if the source does not provide an objective standard (e.g., subjective records such as “equipment noise levels”), the source calibration method is not suitable. In such cases, other methods like cross-validation or logical checks should be used for data verification.