What Types of Float Flowmeters Are There? Where Are They Applied?

Float flowmeters are widely used in various flow measurement applications. According to statistics, about 15% of domestic flow measurements utilize float flowmeters. There are two types: glass and metal.

Glass Float Flowmeter: Suitable for measuring small to medium and micro flow rates. It can only display the flow locally. The corrosion-resistant glass float flowmeter can measure various acidic, alkaline, and chlorine media, except for hydrofluoric acid.

Metal Float Flowmeter: There are standard and special models. The standard metal float flowmeter is used for small to medium flow measurement and provides local readings and remote signal transmission (air or electric), with alarm and accumulation features. Special models include:

Jacketed Metal Float Flowmeter: Allows heating or cooling media to pass through the jacket, preventing the measured medium from crystallizing or vaporizing. It also helps maintain the viscosity of high-viscosity media.

Corrosion-Resistant Metal Float Flowmeter: Used for corrosive media measurement. These come with fluoroplastic linings or are made from corrosion-resistant metals like titanium, molybdenum, and zirconium.

High Temperature and High Pressure Models: Designed to withstand extreme conditions.

Is the Float in the Float Flowmeter Rotating?

In the past, glass tube float flowmeters featured a rotating float to avoid friction with the pipe wall and prevent measurement errors due to the float not being centered in the conical tube. The float had a slotted design that kept it rotating in place.

However, rotating floats are now less common due to their susceptibility to viscosity effects. Nowadays, most floats are designed to be stationary. To ensure stability, some float flowmeters are equipped with guide rods in the conical tube to prevent the float from sticking to the wall, while others have ribbed walls and grooves on the float to maintain its vertical alignment.

Why Are Floats in Float Flowmeters Made in Different Shapes?

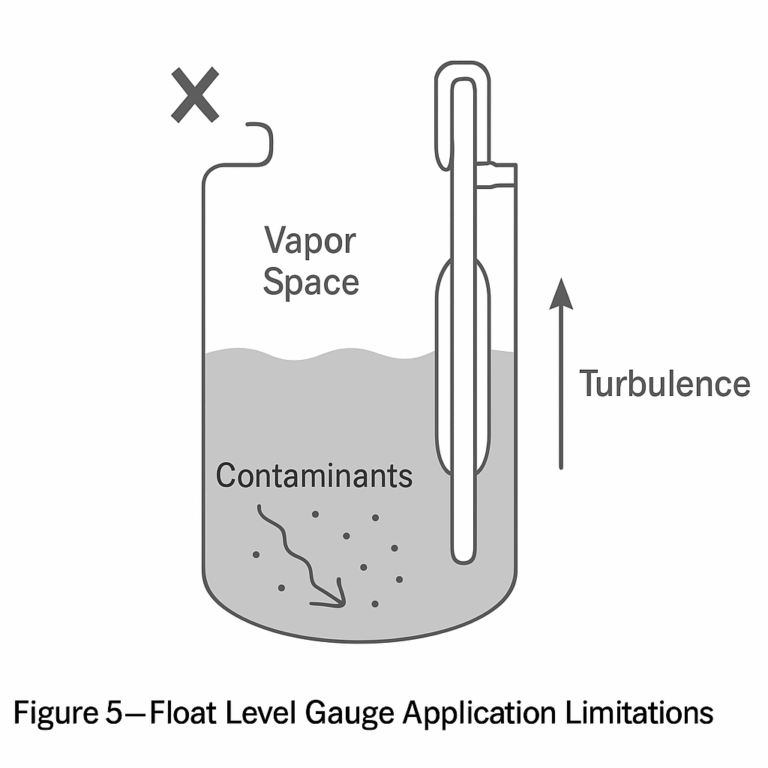

The flow coefficient in a float flowmeter is affected when the Reynolds number of the fluid being measured falls below a certain threshold. Below this threshold, the flowmeter’s measurement accuracy is compromised. Therefore, the Reynolds number of the fluid must exceed this threshold for accurate measurement.

Experimental data shows that different geometric shapes of floats have different threshold Reynolds numbers. To accommodate fluids with varying viscosities, floats are designed in various shapes. Common float shapes include:

(a) Hammer-Style Float: It has a large flow coefficient but is more sensitive to viscosity.

(b) Viscosity-Stable Float: It has a smaller flow coefficient than (a) but is less affected by viscosity.

(c) High Viscosity-Stable Float: This type remains stable even at very low Reynolds numbers, but it has the smallest flow coefficient.

What Should Be Considered When Installing Remote Float Flowmeters?

When installing remote float flowmeters, the following installation guidelines should be observed:

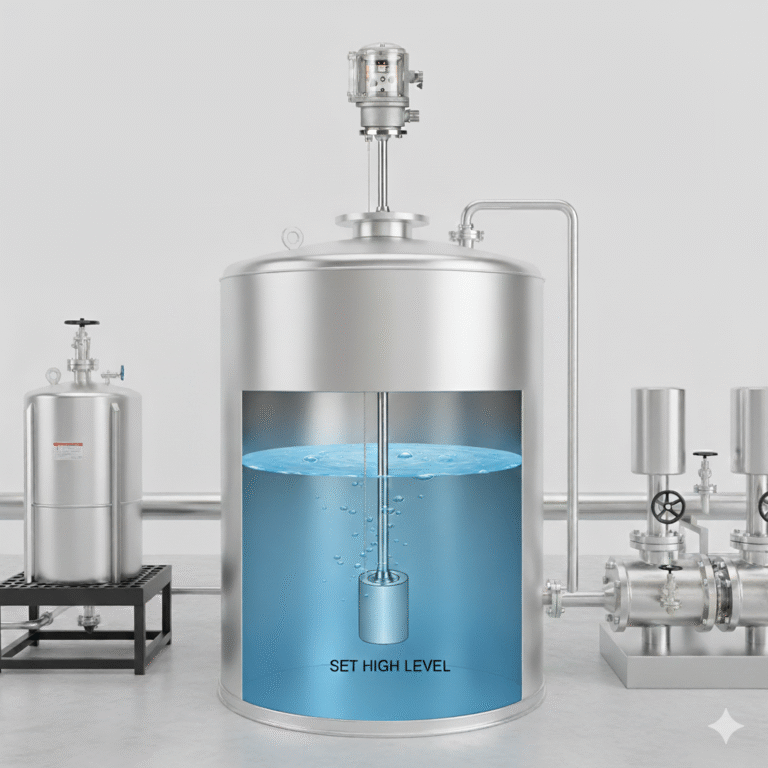

Vertical Installation: The float flowmeter must be installed vertically, and the flow direction should be from bottom to top. A spirit level should be used to ensure vertical alignment.

Allow for Float Movement: Ensure there is enough straight pipe section so that the float guide rod has room to move up and down freely.

Easy Maintenance: To make maintenance easier, install a short pipe section with the flowmeter. This allows for the flowmeter and the short section to be removed together, preventing damage to the float guide rod.