Radar level meters are often the go-to choice for a wide range of measurement scenarios due to their excellent adaptability. However, when faced with a variety of antenna types—such as rod, water drop, horn, parabolic, planar, guided wave, and sleeve antennas—choosing the right one can be daunting. This article compares different types of antennas based on accuracy, interference resistance, and installation/maintenance ease, providing real-world examples to help you select the best antenna for your specific conditions.

Choosing the Right Radar Level Meter Antenna

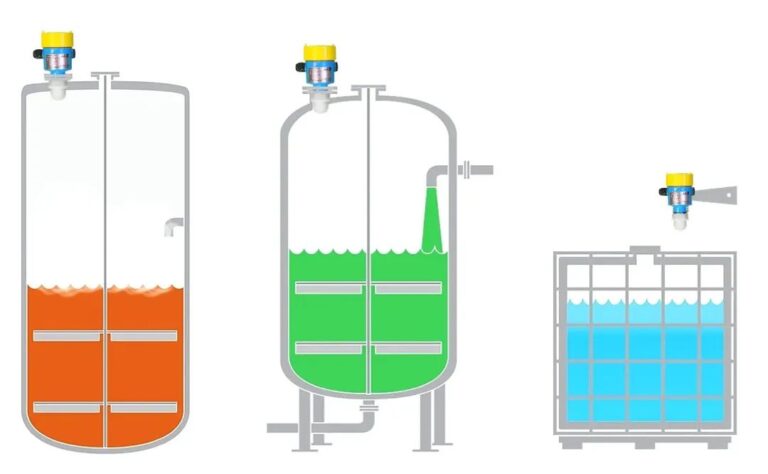

Radar level meters are ideal for continuous level measurement in challenging environments, including those with high temperatures, steam, dust, or volatile gases. They are widely used in industries such as chemical, energy, petrochemical, pharmaceutical, and cement.

Radar level meters are divided into two main categories:

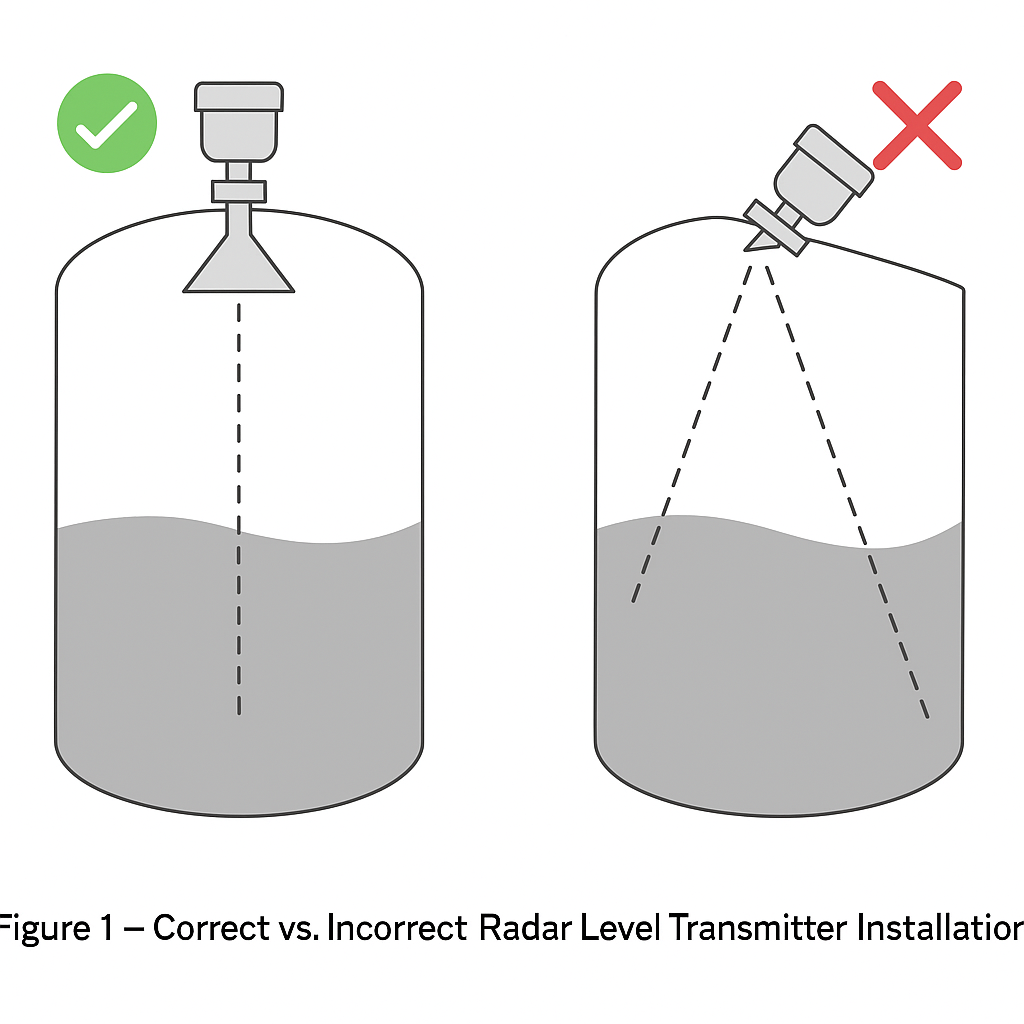

Non-contact radar level meters: These commonly use horn or rod antennas to transmit and receive microwaves. Installed at the top of the vessel, they do not come into contact with the measured medium. This setup is easy to install and requires minimal maintenance, unaffected by the gas composition, dust, or temperature changes inside the tank.

Contact radar level meters: These utilize metal waveguides (rods or cables) to conduct microwaves. The antenna reaches the bottom of the tank, with microwaves being transmitted along the guide and reflected back from the material’s surface.

Types of Radar Level Meter Antennas

Rod Antenna

Material: Typically made of corrosion-resistant materials like PTFE or polypropylene.

Applications: Ideal for measuring corrosive media in large tanks or silos with relatively simple internal structures. They offer a wide microwave emission angle (~30°), which can lead to more noise and lower accuracy in complex tank environments. However, they are easy to clean and work well in non-volatile mediums.

Limitations: Less effective for precise measurements in complex structures due to lower signal-to-noise ratio.

Water Drop Antenna

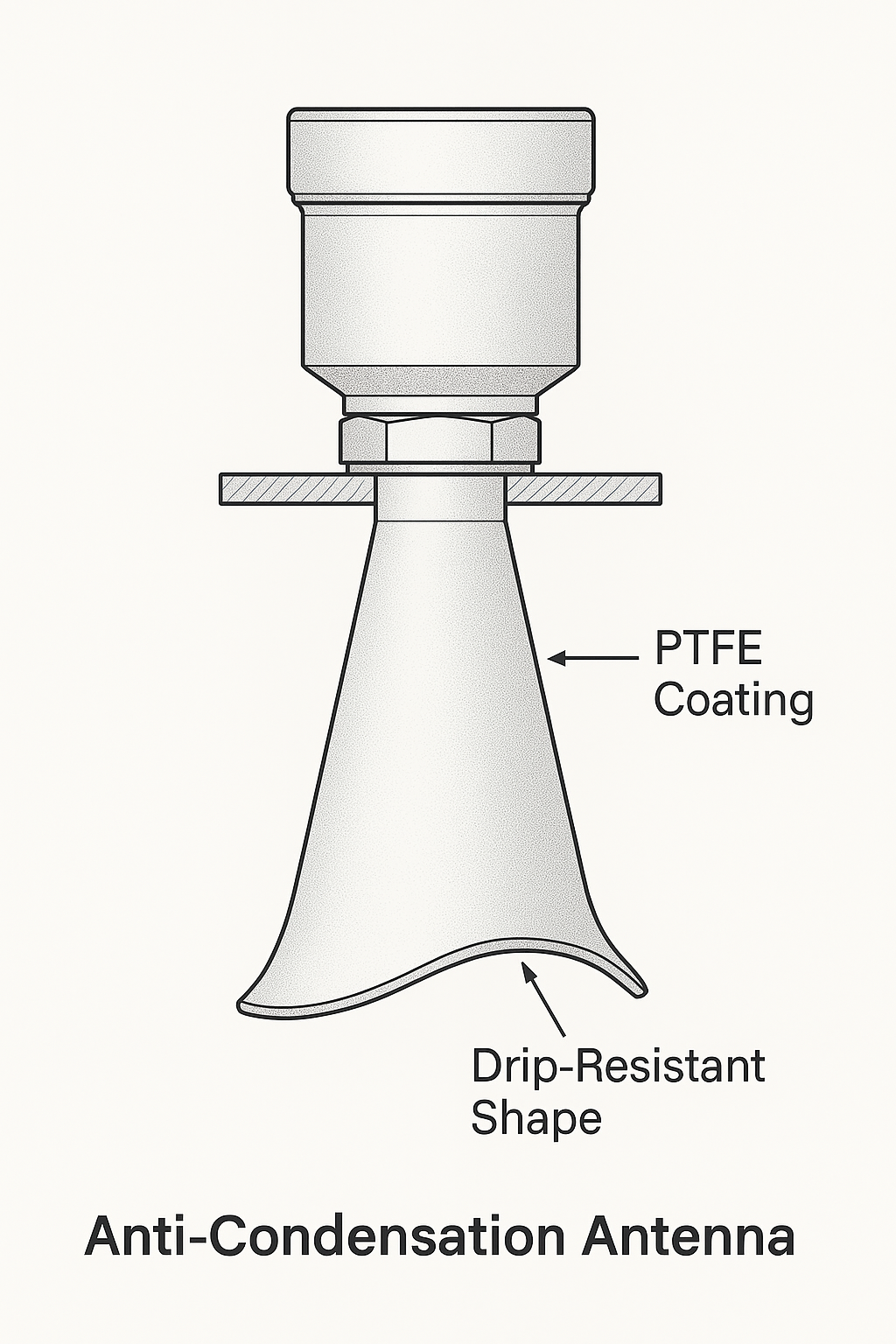

Design: This antenna design extends the radar emitter above the tank, reducing condensation interference on the signal.

Applications: Best suited for high-temperature applications, such as oil storage or steam-related environments. The design helps to prevent condensation and material buildup.

Advantages: Minimizes interference from liquid condensation, making it ideal for challenging conditions.

Horn Antenna

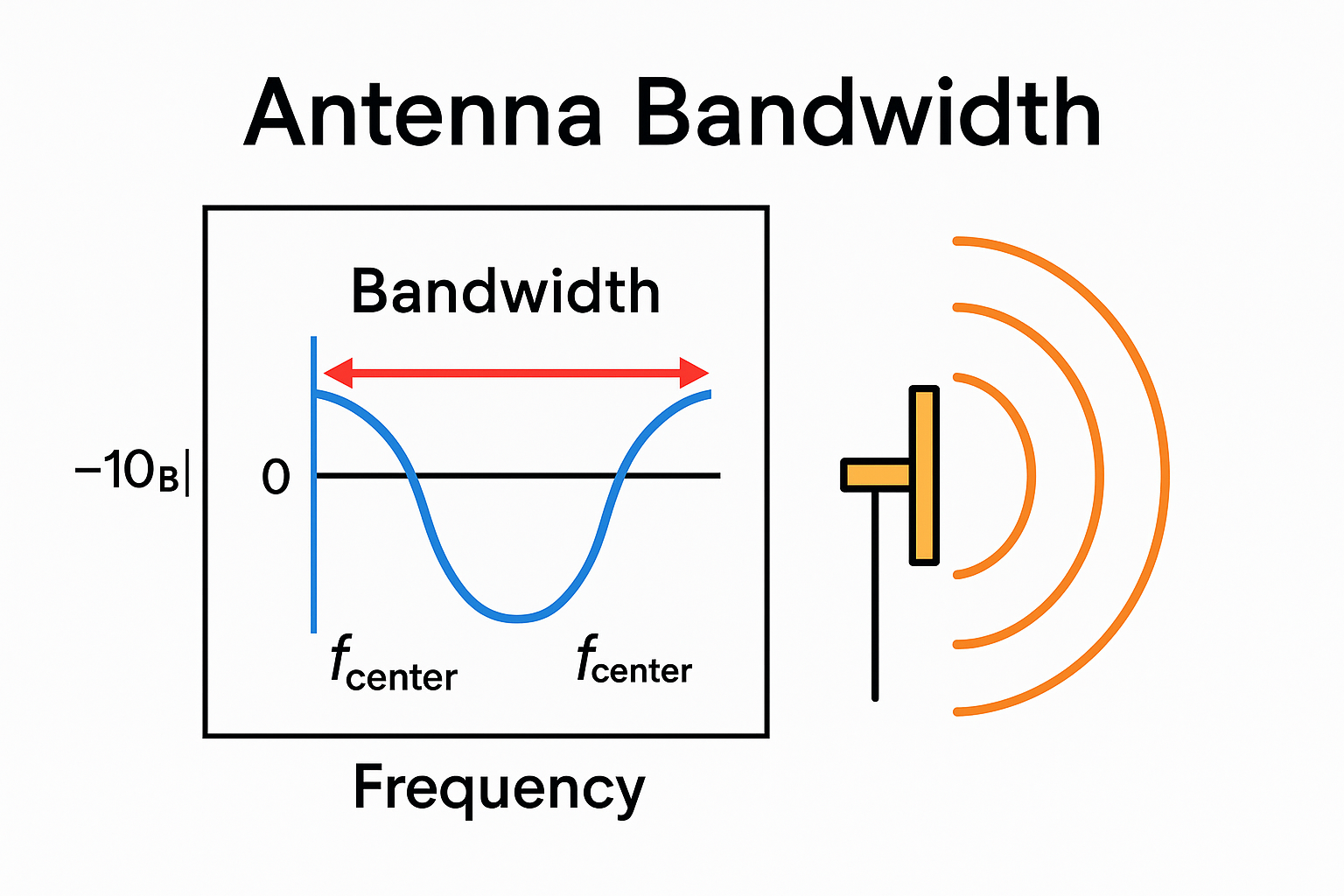

Design: A larger diameter horn antenna reduces the emission angle, leading to improved measurement accuracy, especially in high-frequency radar systems.

Applications: Commonly used in buffer tanks, storage tanks, and reaction vessels, but not recommended for corrosive media.

Limitations: Installation can be difficult due to its larger size, and performance improvements are limited beyond a certain diameter increase.

Parabolic Antenna

Design: Offers a narrow emission angle (as low as 3.5°), making it ideal for precise measurement over long distances or through obstructions.

Applications: Suitable for high-frequency radar systems requiring high precision and minimal interference.

Limitations: Complex installation, especially in floating roof tanks, and maintenance challenges due to heavy and large reflective panels.

Planar Antenna

Design: Utilizes a flat array of multiple points for transmission, offering high precision (±1mm).

Applications: Primarily used in precision metering applications such as high-accuracy storage tank measurements.

Advantages: Excellent for applications requiring very precise measurements, offering excellent resistance to environmental variations.

Guided Wave Radar Antenna

Design: Uses metal or cable waveguides to conduct microwave signals directly to the material surface.

Applications: Ideal for measuring solid materials and low-dielectric constant liquids.

Advantages: Less affected by environmental factors such as dust, steam, or condensation, making it highly reliable.

Limitations: Installation may require additional infrastructure, such as metal platforms for maintenance, increasing complexity and cost.

Sleeve Antenna

Design: A specialized antenna for low dielectric constant materials or when strong surface fluctuations occur.

Applications: Suitable for materials with low dielectric constants (1.6-3) or situations where false reflections are common due to swirling fluids or tank designs.

Advantages: Reduces interference and enhances measurement reliability in challenging environments.

Comparing Key Performance Metrics of Radar Level Meter Antennas

The three most common types of radar level meter antennas—parabolic, guided wave, and horn—each have their own unique set of characteristics:

Performance Stability: Conical antennas generally offer the most stable performance over time, with fewer instances of failure or measurement interruptions.

Cost: Parabolic antennas are the most affordable option, suitable for applications where measurement precision is not critical and the budget is limited.

Measurement Precision: Guided wave antennas provide the highest precision, followed by conical antennas. Parabolic antennas, while economical, have the highest potential for measurement errors and should be used with caution in high-precision applications.

Choosing the Right Antenna Based on Application

Floating Roof Tanks: For large-volume floating roof tanks, guided wave antennas are recommended due to their precision and ability to handle complex conditions. Although they require special installation and maintenance procedures, their long-term performance justifies the extra effort.

Small-Scale or Less Complex Tanks: For smaller tanks or simpler applications, parabolic antennas are a cost-effective choice, though they may not be suitable for environments requiring the highest level of accuracy.

In conclusion, selecting the right radar level meter antenna involves balancing cost, performance, and the specific demands of your environment. By considering the antenna types, their installation requirements, and their application suitability, you can ensure accurate and reliable level measurements.

Final Thoughts

When selecting a radar level meter antenna, it’s essential to account for factors such as the physical environment, required accuracy, and ease of maintenance. The right choice will help optimize performance, reduce interference, and ensure long-term reliability in various industrial settings.