1. Working Principle (Core Logic: Magnetic Field Interaction + Time Difference Calculation)

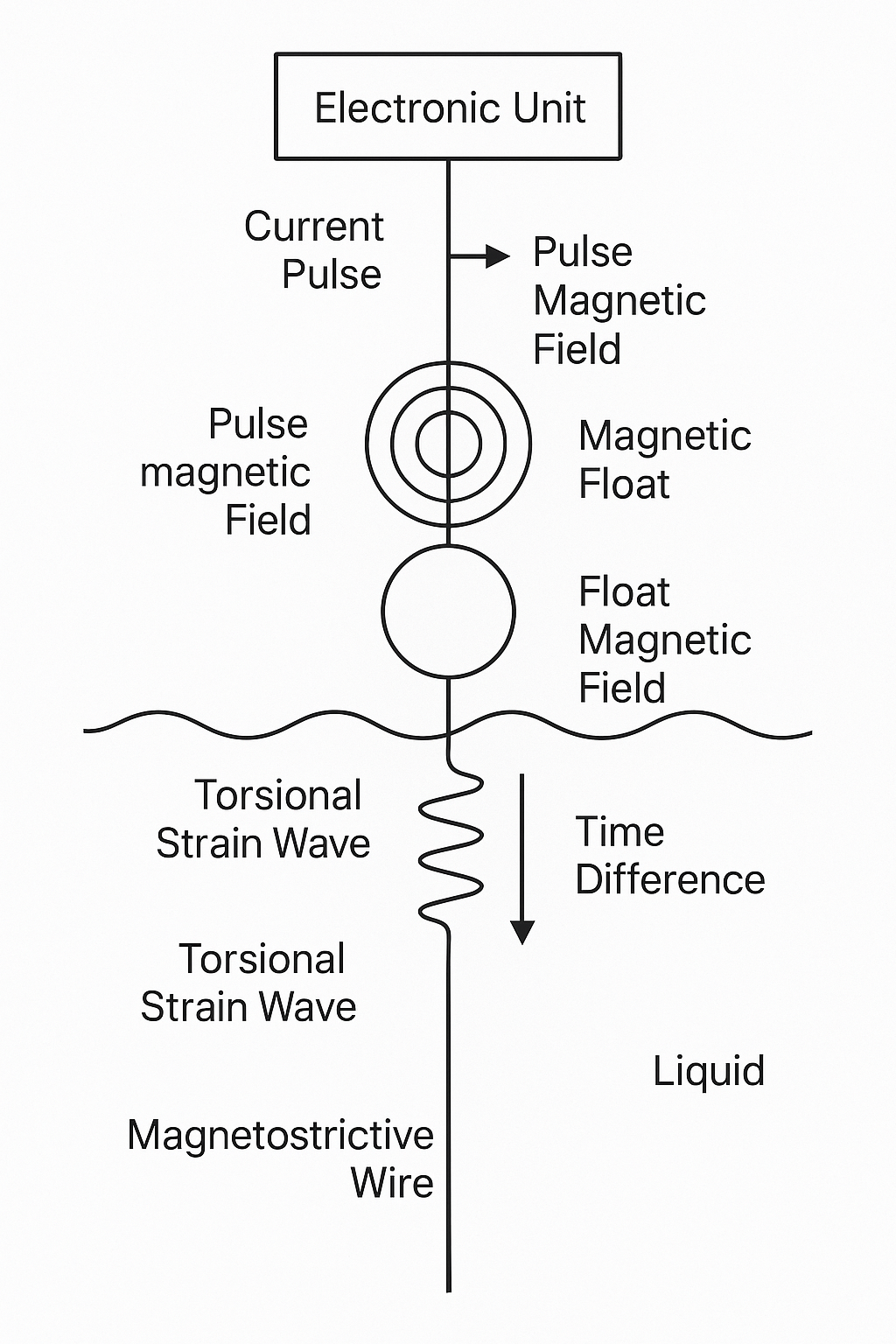

A magnetostrictive level gauge measures liquid level based on the magnetostrictive effect. The measurement process can be summarized as follows:

The electronic unit sends a current pulse into the magnetostrictive wire located inside the probe. This pulse generates a circular magnetic field along the wire.

A magnetic float, which moves with the liquid surface, carries a permanent magnetic field. When the two magnetic fields intersect, a torsional strain wave (magnetostrictive effect) is produced.

The torsional wave propagates back along the wire to the electronic unit.

The electronics calculate the precise time difference between “pulse emission” and “torsional wave reception.”

Using the known wave propagation velocity, the distance is calculated with the formula:

Distance=Wave Speed×Time DifferenceThis distance corresponds directly to the float position, i.e., the current liquid level.

2. Core Applications

Magnetostrictive level gauges are primarily used for high-precision measurement of liquid levels or liquid–liquid interfaces. Typical features include accuracy up to ±0.1% of full scale, excellent stability, and long service life.

They are widely applied in:

Petrochemical industry: measurement of crude oil, solvents, and refined products

Water treatment: sewage, chemicals, and dosing tanks

Food & pharmaceuticals: beverage tanks, medical solutions

Power industry: transformer oil tanks, boiler water tanks

The instruments can be customized for corrosive, high-temperature, and high-pressure environments with suitable materials and models.

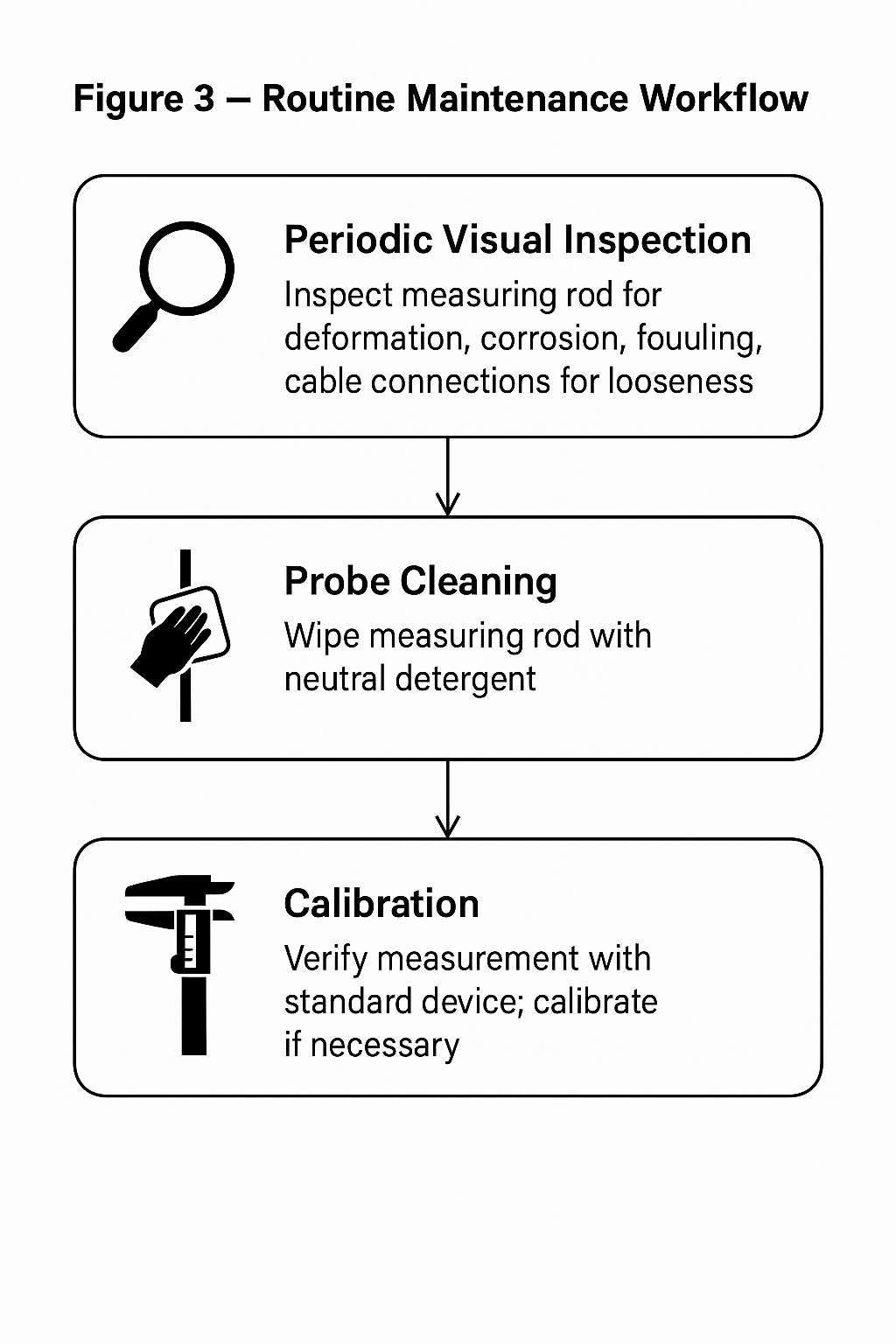

3. Routine Maintenance (3 Key Points)

To ensure reliable operation and maintain accuracy, the following checks are recommended:

Visual Inspection (monthly): Check the probe for deformation, corrosion, or scaling. Ensure cable connections are tight and free from mechanical damage.

Probe Cleaning (quarterly, or more frequently for dirty media): Wipe the probe with a soft cloth and neutral cleaning agent to remove oil, scaling, or crystallization that may interfere with the magnetic signal.

Calibration & Verification (annually): Compare readings against a standard level device (e.g., calibration cylinder). If deviations exceed tolerance, perform recalibration via the instrument menu or configuration software.

4. Key Selection Parameters (5 Critical Factors)

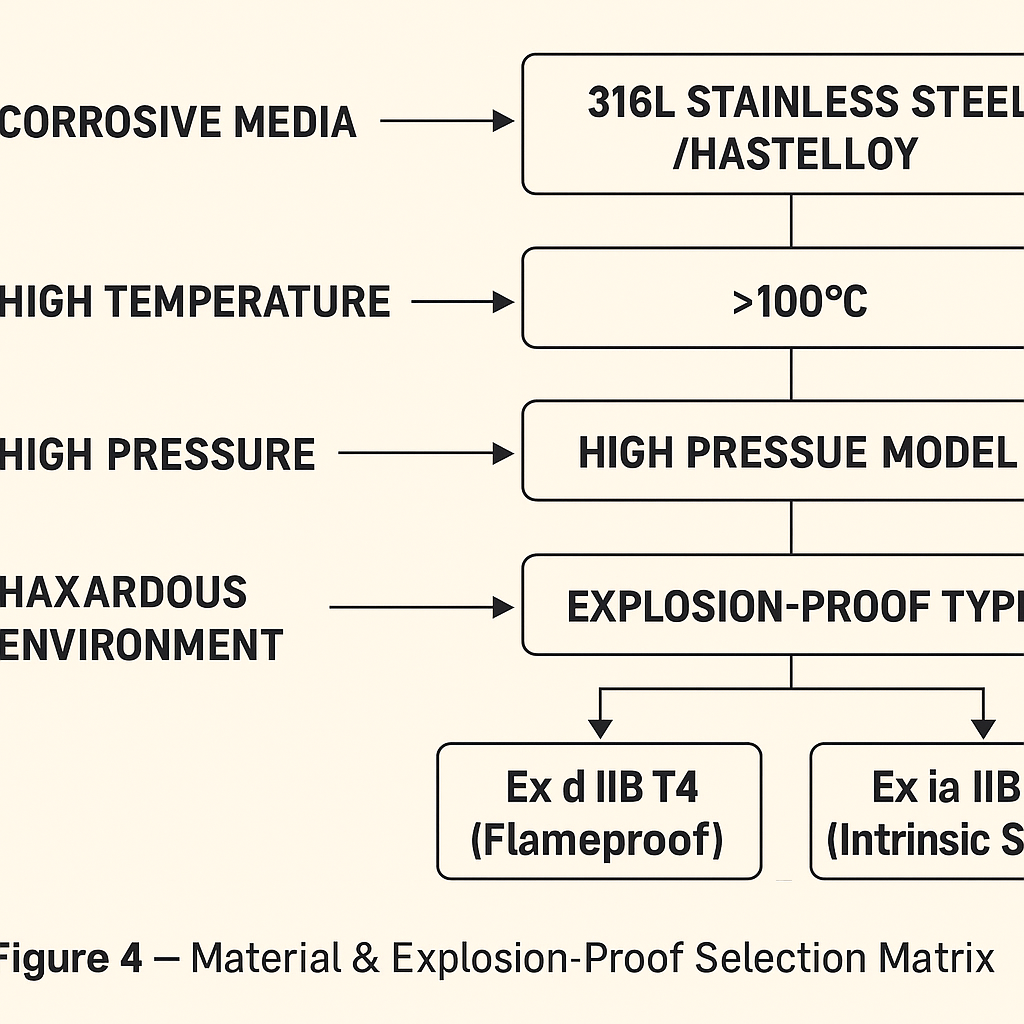

When selecting a magnetostrictive level gauge, the following aspects should be considered:

Measuring Range: Select according to actual liquid height (e.g., 0–3 m, 0–8 m). A 10–20% safety margin is recommended to avoid exceeding the range.

Medium Characteristics:

Corrosive liquids → 316L stainless steel or Hastelloy probe

High temperature (>100 °C) / High pressure (>1 MPa) → special reinforced model

Installation Method:

Top-mounted: vertical probe insertion (for open/closed tanks)

Side-mounted: horizontal probe installation (for horizontal vessels)

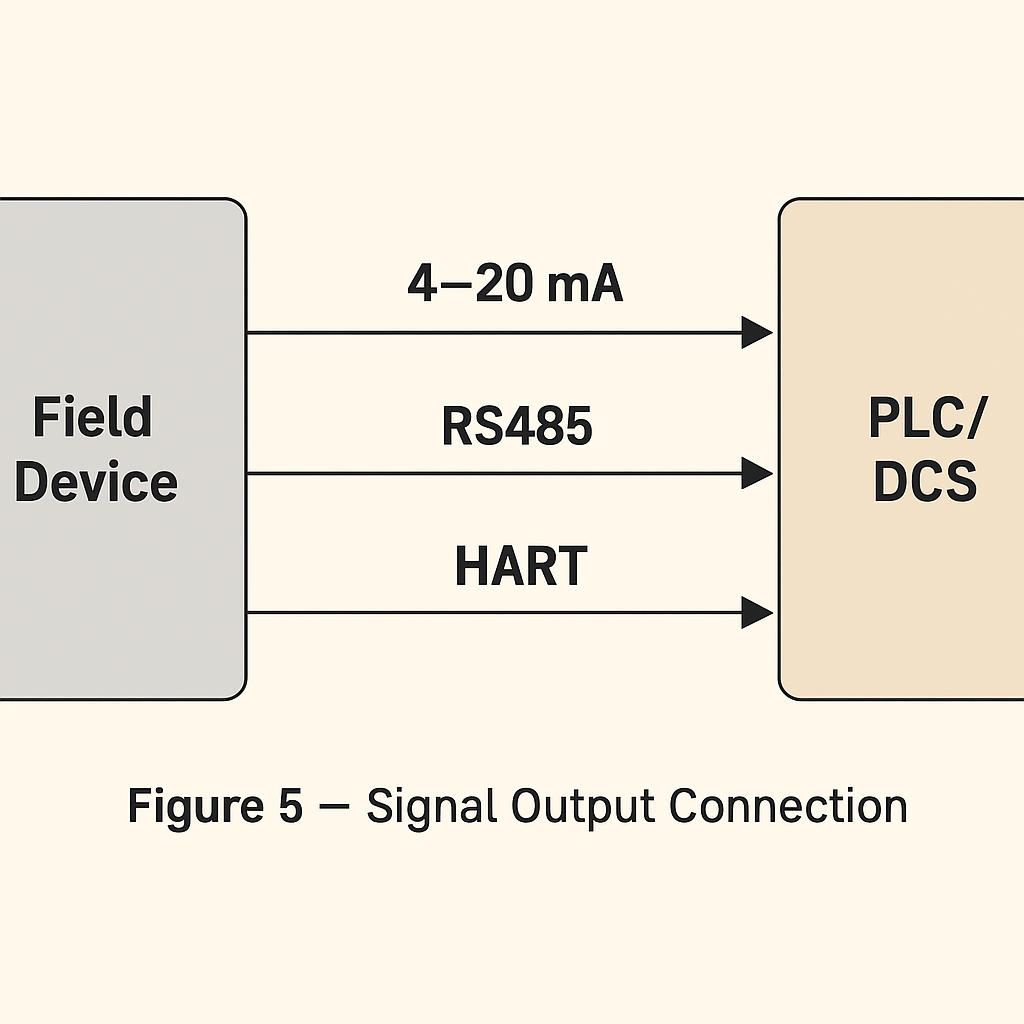

Output Signal:

Standard: 4–20 mA analog signal (compatible with PLC/DCS)

Optional: RS485 (Modbus), HART communication for remote monitoring

Explosion-Proof Rating:

Hazardous areas require explosion-proof design

Common certifications: Ex d IIB T4 (flameproof), Ex ia IIB T4 (intrinsic safety), ATEX/IECEx approval

5. Advantages at a Glance

High accuracy: up to ±0.1% FS

Maintenance-free design: no moving parts inside the electronics

Long service life: >10 years under normal operation

Versatile applications: suitable for clean, dirty, or interface measurement

Digital integration: supports advanced protocols for industrial automation