In chemical processing plants, equipment start-up and shutdown are common operations. For short-term shutdowns, instrumentation impact is minimal. However, during large-scale maintenance shutdowns or extended outages due to specific events, instrument personnel must follow strict procedures to ensure safety and reliability. This article outlines the key tasks and precautions for instrument technicians during plant shutdown and start-up (excluding new plant commissioning).

🔻 I. Instrumentation Work During Plant Shutdown

Plant shutdown is relatively straightforward, but instrument personnel should pay attention to the following:

Close Collaboration with Process Team

Communicate closely with process operators to align shutdown timing and responsibilities.Understand Maintenance Schedules

Be aware of planned shutdown duration and equipment overhaul schedules.Instrument Removal According to Equipment Maintenance Progress

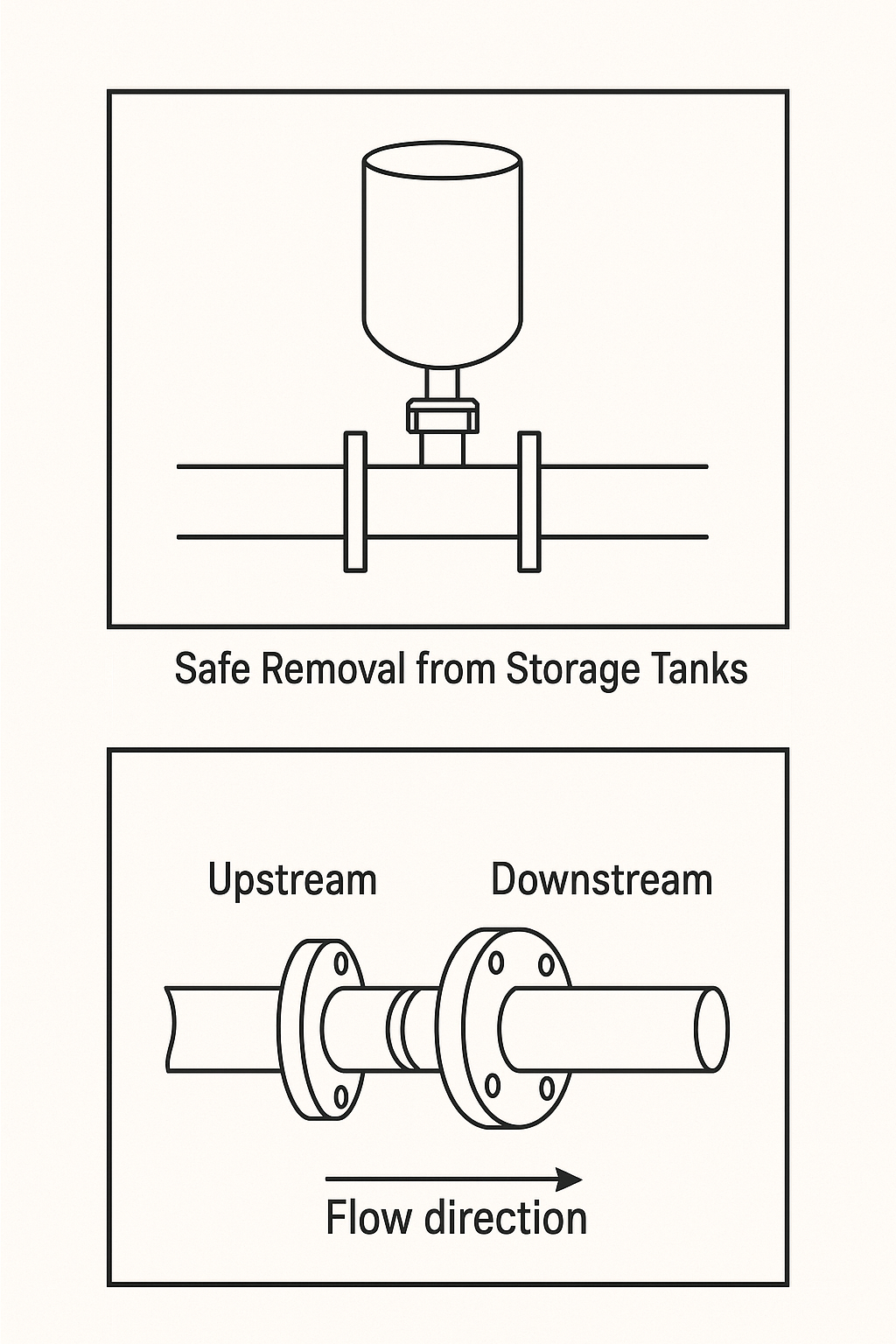

Remove instruments mounted on equipment to be serviced, such as thermocouples, RTDs, differential pressure transmitters, float level gauges, capacitive level transmitters, pressure gauges, etc. Always cut off instrument power and air supply before removal.Safe Removal from Storage Tanks

For DP transmitters on tanks, confirm the tank is empty or that the liquid level is below the tapping flange. Blind flanges should be installed immediately after removal.Cable Protection After Removal

Wrap power and signal cable ends with insulating tape and place them properly. Always power off transmitters before disconnection.Safe Pressure Relief Before Removal

When removing pressure gauges or transmitters, be alert to potential blockage in pressure taps that may cause sudden material discharge. First loosen bolts slightly to relieve trapped pressure before removal.Shut Off Air Supply for Pneumatic Devices

For I/P converters, pneumatic positioners, etc., close air supply and loosen filter-regulator connections.Orifice Plate Handling

When removing concentric orifice plates, note the flow direction. Also check for pipeline sag that may complicate reinstallation due to insufficient pipe support.Marking and Identification

Clearly label each instrument’s tag number for correct reinstallation to avoid mismatches that may cause malfunctions.For Interlocked Instruments

Switch to manual mode before disconnection to avoid system trips.

🟢 II. Instrumentation Work During Plant Start-Up

Successful plant start-up reflects high-quality maintenance. If not well-prepared, instrument faults may delay start-up or even halt production.

Key tasks for instrument technicians during start-up:

Coordinate Closely with Process Operations

Ensure timely installation of instruments post leak/pressure tests. Require operator supervision and use safety measures during installation.Ensure Correct Instrument Reinstallation

Double-check all instrument tags. Incorrect installation is difficult to trace and can lead to undetected errors.Power Supply Management

After completing wiring checks, energize instruments via local and panel circuit breakers. For 24VDC systems, verify output voltage to avoid damage.Air Supply Purging

Clean the air supply system thoroughly to remove rust, dust, and gel from filters. Purge main air headers, branch lines, and regulators on all pneumatic instruments to prevent clogs.Orifice Plate Installation Check

Ensure correct orientation, clean and smooth pipe inner surfaces, and verify gaskets and centering. Open pressure taps after installation.Control Valve Precautions

Match valve body flow direction with process flow. For dirty fluids, flush the line before installation. Fully open isolation valves and then back off half a turn.Negative Pressure Side Filling for DP Level Measurement

When using liquid-filled capillaries, refill the reference leg with the correct liquid to match negative span settings.Fill Isolation Liquid for Pressure Transmitters

Ensure impulse lines are completely filled. Close root valves during filling to avoid high-pressure blowout.Leak Test Pneumatic Connections

Use soap solution to check fittings and avoid air signal leakage.Steam Flow Measurement

Close high and low pressure valves, open the balance valve, wait for steam to condense, then open the transmitter. Alternatively, pre-fill the impulse line with cold water to avoid start-up vibration and damage.Thermocouple and RTD Wiring

Ensure correct polarity for thermocouples. For RTDs, avoid mixing A/B/C terminals.Loop Calibration and Signal Verification

Conduct loop checks between field devices and DCS. Verify valve positions, controller outputs, and indication consistency.Switch to Automatic Control Last

Activate automatic control only after confirming all instrumentation and process conditions are stable.Start-Up of Metal Tube Rotameters

Bypass initial flow to prevent debris damage. Follow the correct valve opening sequence: open bypass → then inlet → outlet → close bypass.

✅ Conclusion

Proper handling of instrumentation during shutdown and start-up is critical for ensuring plant safety, reducing downtime, and avoiding costly mistakes. Instrument technicians must operate carefully, follow procedures, and maintain close coordination with process personnel.