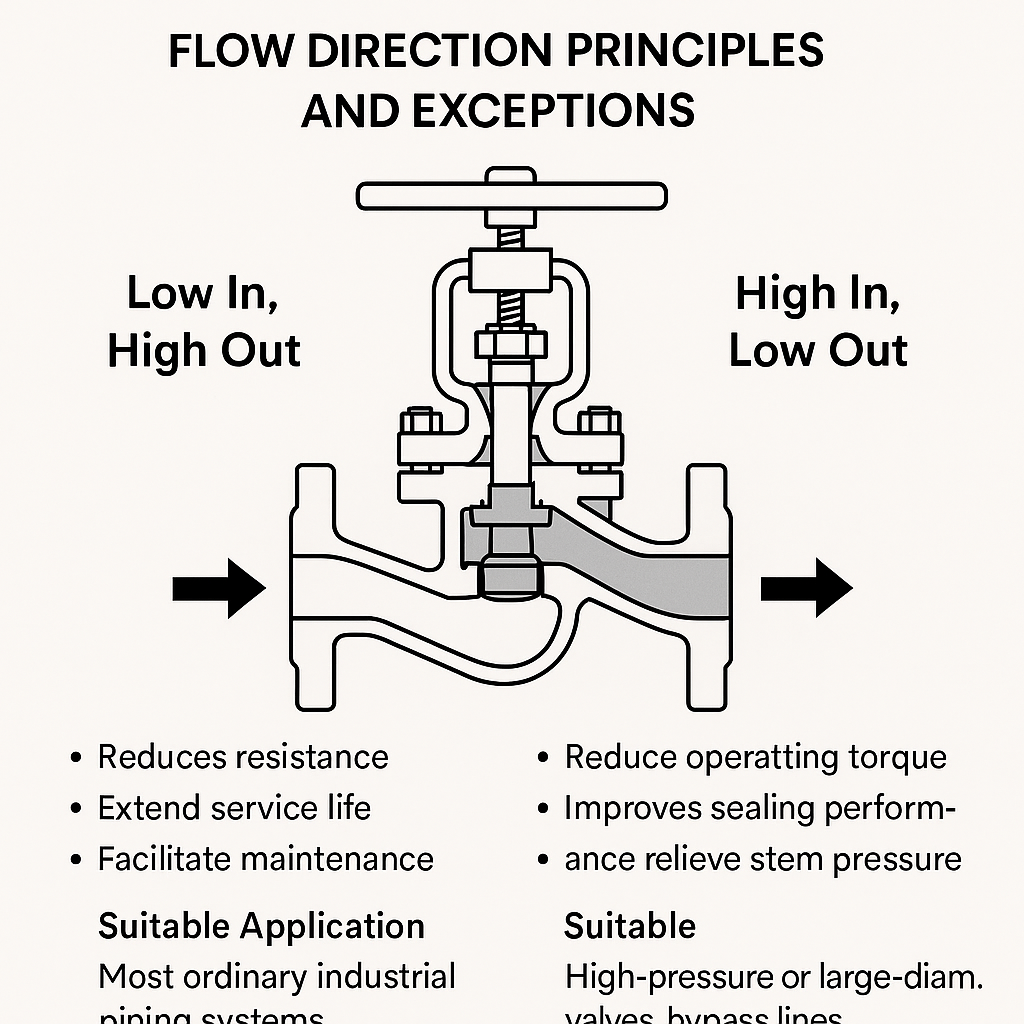

Globe valves are commonly used in industrial pipelines for fluid control, especially where precise throttling or frequent operation is needed. One frequently asked question is whether the flow direction of a globe valve must always follow the “low in, high out” principle.

While “low in, high out” is the standard design in most installations, it is not absolute. In some special conditions, the flow direction can and should be reversed. This article explores the reasoning behind each configuration, when to use them, and how to avoid installation errors.

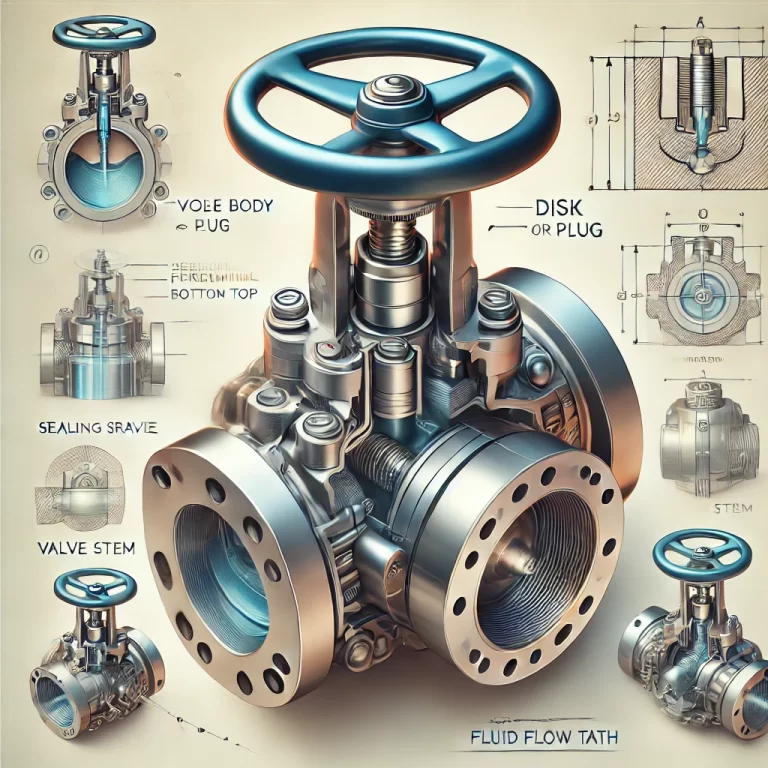

🔧 How Does a Globe Valve Work?

A globe valve operates by the vertical movement of a disc (plug) that regulates flow. The disc is attached to a stem, which is moved up and down by rotating the handwheel. The fluid enters one side of the valve body, passes through the seat beneath the disc, and exits from the other side.

📈 Why “Low In, High Out” is the Standard Configuration

✅ 1. Reduces Flow Resistance

When fluid enters from below the seat and exits from the top, it produces a more stable laminar flow through the valve body. This mimics the effect of a gentle curve or elbow, reducing turbulence and flow resistance. Additionally, this flow direction assists the upward movement of the valve disc, reducing the torque needed to open the valve.

✅ 2. Protects Valve Seat and Disc

The disc and seat of a globe valve are finely machined for tight sealing. With bottom-inlet flow, the disc is pressed evenly against the seat during closure. If flow enters from the top, it may cause uneven force distribution on the sealing surface, leading to localized wear and shorter service life.

✅ 3. Improves Packing Seal Life and Maintenance Safety

In the “low in, high out” configuration, when the valve is closed, the upstream pressure does not act directly on the packing (the sealing area around the stem). This reduces the risk of leakage and allows for safer maintenance, such as replacing packing under shutdown conditions without depressurizing the entire pipeline.

⚠️ When “High In, Low Out” Is Preferable

Though uncommon, the “high in, low out” configuration is appropriate in the following situations:

🔹 1. High-Pressure or Large-Diameter Valves (DN > 100 mm)

In high-pressure applications, if the fluid enters from the bottom, the stem must overcome full system pressure to open the valve, requiring a larger actuator or more manual force.

Allowing the fluid to enter from the top reduces opening torque, enabling a thinner stem and smaller actuator.

It also allows the fluid pressure to assist in pressing the disc more tightly onto the seat when closed, improving sealing reliability.

🔹 2. Bypass or Equalizing Lines with Dual Globe Valves

In systems with two globe valves installed in series (e.g., on bypass lines for pressure balancing or isolation), the second valve is often configured as “high in, low out.”

This minimizes long-term exposure of the packing and bonnet to high pressure and temperature, extending the valve’s reliability in standby conditions.

🔹 3. Boiler Vent and Drain Valves

These valves operate infrequently but must seal tightly to prevent pressure loss.

Installing them in a “high in, low out” direction uses system pressure to aid in sealing, improving tightness and reducing leakage risk during long idle periods.

✅ Installation Guidelines

Regardless of the chosen flow direction, installation should strictly follow the flow arrow marked on the valve body. Installing the valve against the recommended flow direction can lead to:

Seal failure

Increased torque requirements

Safety hazards

Premature wear or valve malfunction

🧾 Quick Comparison Table: Flow Direction in Globe Valves

| Flow Direction | Advantages | Recommended Use Cases |

|---|---|---|

| Low In, High Out | – Lower flow resistance – Easier opening – Protects packing | Standard piping systems DN ≤ 100 mm Frequent operation |

| High In, Low Out | – Lower operating torque – Better sealing under pressure | High-pressure systems Large-diameter valves Bypass or venting lines |

📌 Conclusion

Although “low in, high out” is the default and most widely used flow direction for globe valves, specific process conditions such as pressure level, valve size, and operational frequency may justify reversing the flow.

Engineers and maintenance personnel must always verify:

Flow direction markings on the valve body

System pressure conditions

Maintenance requirements

Making the right decision will improve system performance, extend valve life, and reduce total lifecycle costs.