1. Introduction

This guide provides detailed instructions for using a digital multimeter in typical industrial scenarios, such as current loop measurement, RTD and thermocouple testing, and voltage measurements. Emphasis is placed on safety, accuracy, and practical steps for on-site diagnostics.

2. Measuring 4–20 mA Current Loop Signals

Method 1: Break-Point Series Measurement

Ensure the loop is powered and stable.

Disconnect one of the signal wires between the transmitter and control system.

Set the multimeter to the DC current range (typically 200 mA) and insert the red probe into the mA jack.

Connect the probes across the break in series.

If the reading is negative, reverse the probes.

⚠ Warning: Never directly connect the probes across the transmitter terminals in current mode — this can cause internal fuse blowout or meter damage.

Method 2: Extra Terminal Tapping

Without removing wires, locate a third (spare) terminal on the transmitter.

Set the meter to mA range.

Connect the red probe to the transmitter’s negative terminal, and the black probe to the third terminal.

Read the output current.

3. RTD (Pt100) Resistance Measurement & Diagnosis

Three-wire RTD Circuit Check

Set the multimeter to resistance (Ω) mode.

Verify meter calibration: short probes and confirm 0Ω.

Disconnect all three RTD wires at the terminal block.

Measure:

Between a–b and a–c: ~110Ω at 25°C

Between b–c: ~0Ω

Fault Conditions:

a–b or a–c < 100Ω: Possible short circuit

a–b or a–c = ∞: Open circuit

If b–c ≠ 0Ω: Wiring error or wire degradation

Field Resistance-to-Temperature Estimation

Use the formula:

Temperature (°C) ≈ (MeasuredΩ – 100) / 0.385Example: If Pt100 shows 162Ω → Temp ≈ (162–100)/0.385 ≈ 161°C

4. Thermocouple Testing

Step-by-Step

Visually inspect for corrosion, leaks, or mechanical damage.

Use resistance mode to test continuity:

Standard thermocouple: <2Ω

Mineral insulated cable: <50Ω

1kΩ: Likely broken

No Thermoelectric Signal

If display remains fixed or maximum value shows:

Check for open circuit

Inspect internal junction for mechanical or heat damage

Weak/Incorrect Signal

Possible causes:

Improper insertion depth

Scaling or corrosion on protection tube

Moisture ingress

Electrode thinning or color change

Poor weld at measuring junction

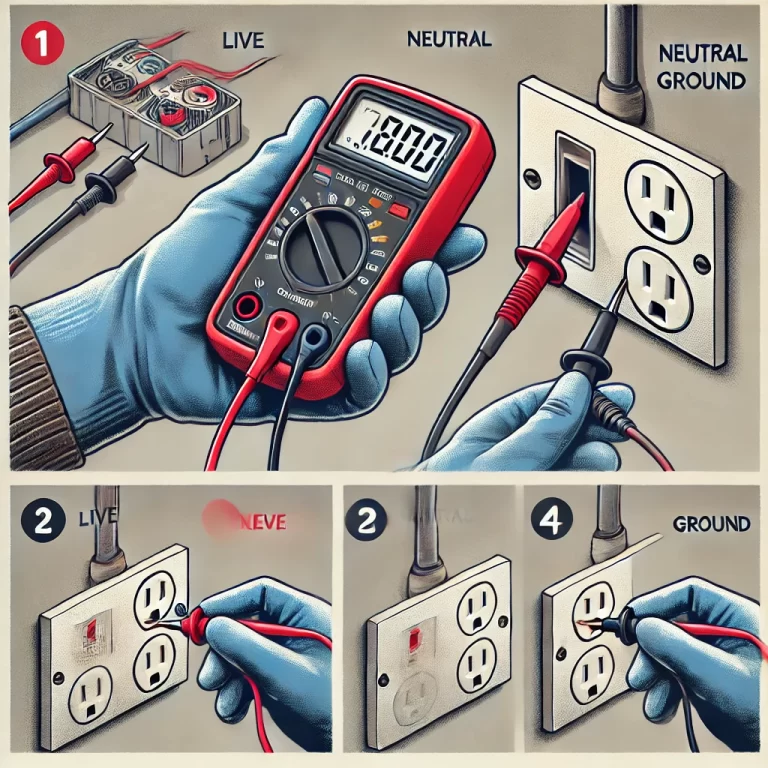

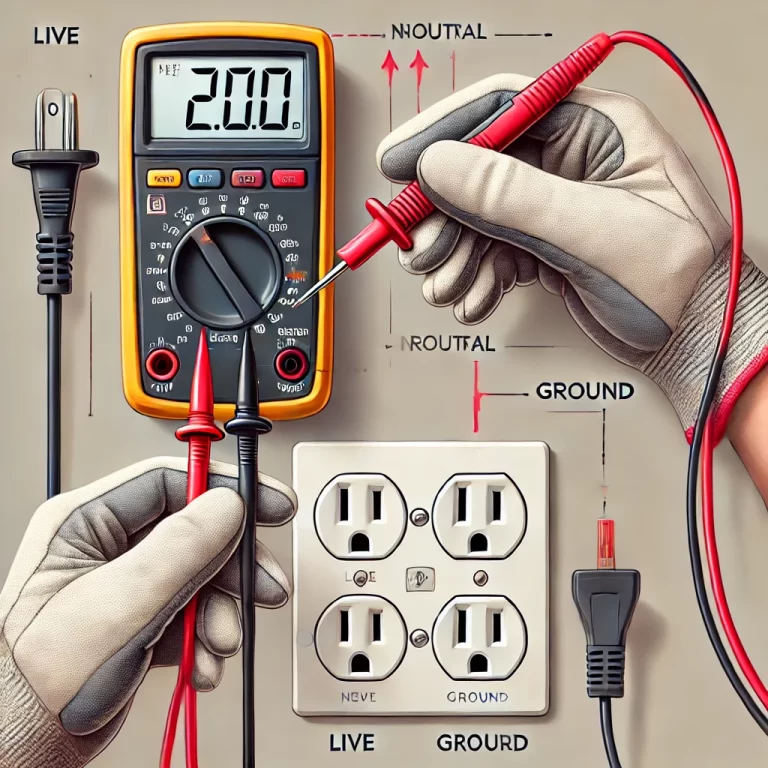

5. Voltage Measurement

DC Voltage

Black probe to COM, red to V/Ω.

Set meter to V– (DC), select appropriate range.

Connect across power source/load.

AC Voltage

Same probe setup.

Set meter to V~ (AC).

Measure across terminals.

Caution:

Always start with highest range if voltage level is unknown.

“1” on display = Overrange → switch to higher range.

Avoid inputting voltages beyond rated limits to prevent internal damage.

Do not touch probe metal during high-voltage tests.

Beware of false readings due to external electromagnetic interference.

6. General Safety Notes

Never use current mode across voltage sources.

Observe polarity and range settings.

Avoid measuring in wet or explosive environments.

Ensure test leads and multimeter are in good condition.

Always isolate the circuit when in doubt.

7. Conclusion

Proper use of a digital multimeter enhances diagnostic accuracy and ensures operator safety. Familiarity with these methods helps technicians quickly detect faults in transmitters, RTDs, and thermocouples across industrial installations.