Introduction

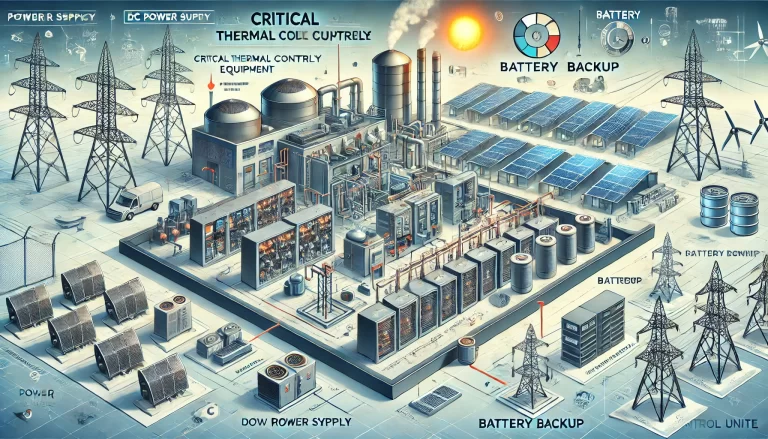

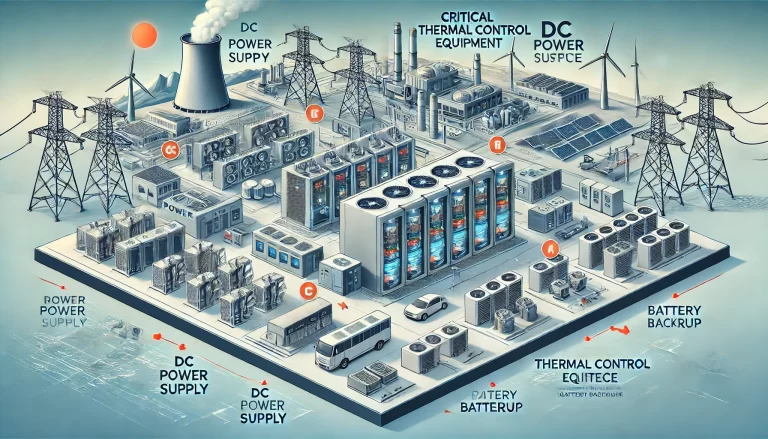

Critical thermal control equipment plays a vital role in various industries, including power plants, aerospace, telecommunications, and industrial automation. Ensuring the reliability and stability of such equipment is paramount, and one of the key considerations in their design is the choice of power supply. Direct Current (DC) power supply is often preferred over Alternating Current (AC) for these critical systems. This article explores the reasons behind this preference and the advantages that DC power brings to critical thermal control equipment.

1. Enhanced Reliability and Power Stability

One of the primary reasons for adopting DC power supply in critical thermal control systems is its superior reliability. Many of these systems operate in environments where power disruptions can lead to severe consequences. DC power systems are generally backed by uninterruptible power supplies (UPS) and battery storage, allowing them to function even during AC power failures.

Continuous Operation: DC power systems can continue running seamlessly in case of an AC outage, ensuring that critical control systems remain operational.

Voltage Stability: DC voltage does not experience frequency fluctuations like AC power, making it more stable and reducing the risk of equipment failure.

2. Superior Resistance to Electrical Interference

Electrical interference and noise can severely impact the performance of precision control systems. DC power offers better immunity against electromagnetic interference (EMI) and radio frequency interference (RFI), which are common in AC-powered systems.

Reduced Harmonics: AC power introduces harmonics that can distort signals and affect the operation of sensitive control devices. DC power, on the other hand, provides cleaner energy.

Lower Transients and Surges: DC systems are less susceptible to voltage spikes and transients, which can cause damage to delicate electronic components.

3. Ensuring Continuous Power Supply in Emergencies

Many critical applications, such as nuclear power plants, rail transit control, and communication networks, require an uninterrupted power supply. DC power systems often include redundant power storage units, such as lead-acid or lithium-ion batteries, ensuring continued operation in case of AC grid failures.

Uninterrupted Backup: Unlike AC systems that rely on generators requiring startup time, DC battery systems provide instant backup power.

Automatic Switching: DC power sources can seamlessly transition between different power sources without affecting the operation of connected equipment.

4. Compatibility with Control and Monitoring Systems

Most control and monitoring devices used in thermal systems, such as sensors, Programmable Logic Controllers (PLCs), and Distributed Control Systems (DCS), operate on low-voltage DC power. Supplying DC power directly to these components eliminates the need for multiple power conversion steps, improving efficiency and reducing potential points of failure.

Reduced Conversion Losses: Converting AC to DC introduces power losses. Direct DC supply minimizes energy wastage and improves efficiency.

Simplified Circuit Design: Using DC power reduces the complexity of power circuits, leading to fewer components and lower maintenance requirements.

5. Lower Maintenance and Extended Equipment Lifespan

Using DC power reduces wear and tear on electrical contacts, relays, and other components, leading to longer equipment life and reduced maintenance needs.

Elimination of Zero-Crossing Issues: AC power cycles through zero voltage, causing contact wear in switching devices. DC power does not have this issue, enhancing durability.

Lower Heat Generation: DC-powered systems tend to generate less heat compared to their AC counterparts, reducing cooling requirements and increasing system longevity.

6. Adaptability to Renewable and Emerging Energy Systems

With the increasing adoption of renewable energy sources such as solar and fuel cells, DC power is becoming more prevalent. Many of these energy sources generate DC power directly, which can be utilized without conversion losses, further improving efficiency in thermal control systems.

Seamless Integration with Solar Power: Solar panels generate DC electricity, making it easier to integrate them with DC-powered control systems.

Compatibility with Microgrids and Smart Grids: Many modern power distribution systems incorporate DC microgrids, which can enhance the resilience and efficiency of thermal control applications.

7. Common Applications of DC Power in Thermal Control Equipment

DC power is widely used in numerous critical applications where thermal control is essential:

Power Plants: Protection relays, monitoring systems, and emergency cooling mechanisms.

Aerospace & Defense: Spacecraft thermal control systems, satellite electronics, and defense radar cooling systems.

Industrial Automation: Precision temperature control for manufacturing processes and robotic systems.

Rail Transport: Signaling and railway track heating systems for snow removal.

Telecommunications: Cooling systems for data centers and transmission equipment.

Conclusion

The adoption of DC power in critical thermal control equipment is driven by its reliability, stability, and superior resistance to electrical disturbances. It ensures uninterrupted operation during power outages, reduces maintenance costs, and is well-suited for integration with modern renewable energy sources. As industries continue to evolve, DC power will play an even greater role in ensuring the efficiency and longevity of essential control systems.