Introduction

Temperature control is a critical factor in the chlor-alkali and polyethylene (PE) industries, as it directly influences production efficiency, product quality, and equipment longevity. Accurate temperature measurement ensures optimal process conditions, minimizes energy consumption, and enhances safety in both industries. This article explores the various applications of temperature instruments in these sectors, focusing on their role in different production processes and considerations for their selection.

1. Temperature Instrumentation in the Chlor-Alkali Industry

The chlor-alkali industry primarily involves the production of chlorine (Cl₂), caustic soda (NaOH), and hydrogen (H₂) through the electrolysis of brine. Temperature monitoring is essential in various stages, including electrolysis, drying, storage, and transportation.

1.1 Electrolysis Process Temperature Monitoring

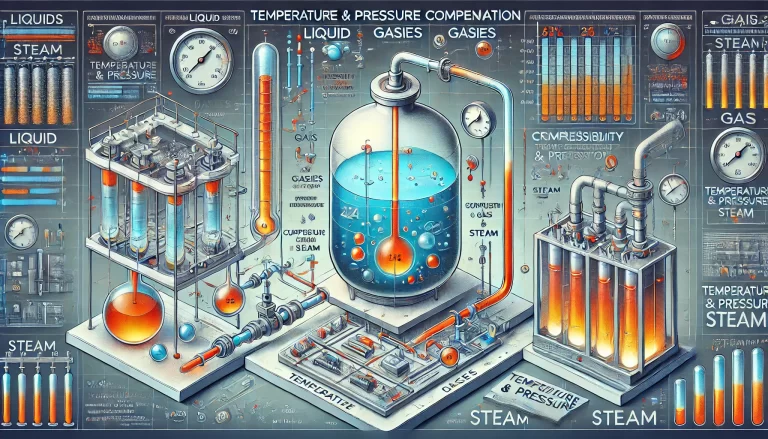

In membrane or diaphragm cell electrolysis, the temperature needs to be maintained within an optimal range (typically 85-90°C) to ensure maximum efficiency and to extend the lifespan of the electrodes.

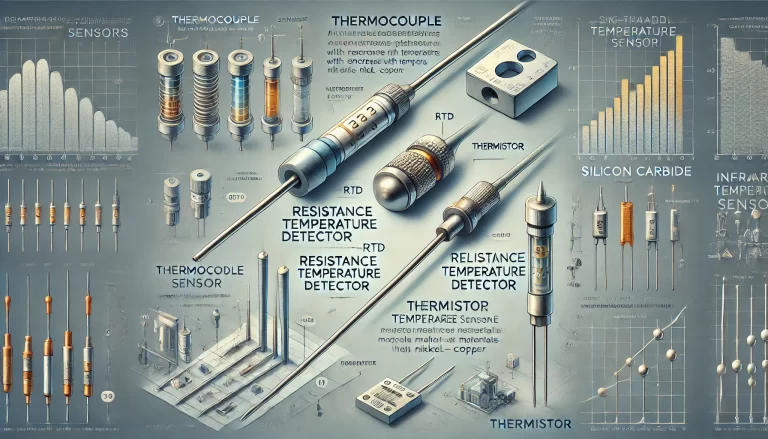

Commonly Used Temperature Instruments:

Thermocouples (K-type, J-type): Chosen for their corrosion resistance and wide temperature range (-200°C to 1300°C).

Platinum Resistance Thermometers (PT100): High-accuracy sensors suitable for monitoring electrolyte temperatures (-200°C to 850°C).

1.2 Chlorine Gas Cooling and Drying

Chlorine gas undergoes cooling and drying to achieve the desired purity levels. The cooling system must maintain temperatures within -50°C to 500°C to prevent condensation and corrosion.

Instruments Used:

Infrared Temperature Sensors: Non-contact measurement suitable for monitoring gas cooling systems.

Corrosion-resistant Thermocouples: Specialized coatings protect against chlorine-induced degradation.

1.3 Caustic Soda Concentration and Evaporation

In the concentration process, the temperature is maintained at 120-150°C to achieve the desired caustic concentration.

Recommended Temperature Instruments:

PT100 Sensors: Ensure accurate monitoring of the caustic solution.

Smart Temperature Transmitters: Integrated with Distributed Control Systems (DCS) for real-time control.

1.4 Storage and Pipeline Temperature Monitoring

Chlorine and caustic soda storage tanks and pipelines require continuous temperature monitoring to prevent leaks and material degradation.

Applicable Instruments:

Explosion-proof Temperature Sensors: Ensure safety in hazardous environments.

Wireless Temperature Sensors: Enable remote monitoring.

2. Temperature Instrumentation in the Polyethylene Industry

Polyethylene production involves polymerization, extrusion, molding, and cooling processes. Temperature control in these stages is critical for achieving desired polymer properties and preventing defects.

2.1 Polymerization Reaction Temperature Control

Polyethylene is produced through various polymerization techniques such as high-pressure (LDPE), low-pressure (HDPE), and gas-phase polymerization. Maintaining reaction temperatures (typically 150-300°C) ensures polymer consistency and prevents side reactions.

Common Temperature Instruments:

High-pressure Resistant Thermocouples (K-type, S-type): Suitable for environments with pressures up to 2000 bar.

Fiber Optic Temperature Sensors: Allow multi-point monitoring within reactors.

2.2 Extrusion Process Temperature Monitoring

During the extrusion process, polymer melts and is shaped into desired forms at temperatures between 180-250°C.

Recommended Sensors:

Embedded Thermocouples: Installed in extruder barrels for real-time temperature feedback.

Infrared Temperature Sensors: Provide non-contact monitoring of the melt.

2.3 Mold Temperature Control

In injection molding and blow molding, mold temperature influences the final product’s surface finish and dimensional stability (typically 50-150°C).

Temperature Monitoring Devices:

Surface Thermocouples: Measure mold temperatures accurately.

Precision Temperature Controllers: Maintain uniform heat distribution.

2.4 Cooling and Solidification

Cooling systems maintain polymer shapes and reduce internal stresses at temperatures between 20-80°C.

Key Instruments Used:

PT100/PT1000 Sensors: Offer high-accuracy monitoring of coolant temperatures.

Digital Temperature Sensors: Provide integration with SCADA systems for remote control.

2.5 Storage and Transportation

Polyethylene pellets require temperature control during storage and transport to avoid agglomeration and degradation.

Recommended Instruments:

Portable Temperature Meters: Ensure monitoring during transportation.

Wireless Temperature Sensors: Enable remote tracking of storage conditions.

3. Selection Criteria for Temperature Instruments

When choosing temperature measurement devices for chlor-alkali and polyethylene industries, the following factors must be considered:

Corrosion Resistance: Materials such as Hastelloy and 316L stainless steel are preferred for highly corrosive environments.

Measurement Accuracy: High precision sensors (e.g., PT100) for critical process control.

Response Time: Rapid response sensors for dynamic processes such as extrusion.

Explosion-proof Design: Compliance with ATEX standards for hazardous areas.

Data Integration Capabilities: Compatibility with PLC, DCS, and IoT systems.

4. Future Trends in Temperature Instrumentation

With the advancement of Industry 4.0, the role of temperature monitoring in these industries is evolving towards smart and automated systems. Key trends include:

Wireless Monitoring Systems: Reducing installation costs and improving flexibility.

Multi-parameter Sensors: Combining temperature, pressure, and flow monitoring.

Predictive Maintenance: AI-driven analytics to predict potential failures.

Conclusion

In the chlor-alkali and polyethylene industries, precise temperature measurement is crucial for process optimization, safety, and quality control. The selection of appropriate temperature instruments ensures efficient operations, reduces maintenance costs, and enhances product quality. As technology advances, the industry is increasingly adopting smart sensors and automated monitoring systems to improve overall efficiency.