Introduction

In modern industrial environments, particularly those with explosive gas atmospheres, ensuring the safety of electrical equipment is critical. Electrical faults, such as sparks or excessive heat, can trigger explosions, leading to significant property damage or even loss of life. To address these challenges, intrinsic safety (IS) technology has emerged as a solution. Intrinsic safety ensures that electrical equipment does not release sufficient energy to ignite explosive substances, even in fault conditions.

However, a common question arises: Can intrinsic safety circuits be used alongside relays? Relays, as widely used electrical control components, play a crucial role in automation and switching circuits. This article explores whether relays can be safely incorporated into intrinsic safety circuits by examining the working principles of both and proposing solutions for compatibility.

Understanding the Basics of Intrinsic Safety

Intrinsic safety is a design approach that limits electrical energy to safe levels, ensuring that even under fault conditions, the circuit does not ignite explosive gases or dust. The core principles of intrinsic safety include:

Low Voltage and Current: Intrinsic safety circuits operate with strictly limited voltage and current, well below the levels required to produce sparks or generate heat capable of ignition.

Energy Limitation: Components like resistors and capacitors are used to restrict energy flow, ensuring that any potential faults do not release excessive energy.

Electrical Isolation: Techniques such as isolation transformers or optocouplers are employed to electrically separate circuits, preventing fault propagation.

These design principles make intrinsic safety a cornerstone in industries such as oil and gas, chemical processing, and natural gas operations, where explosion risks are significant.

The Working Principles of Relays

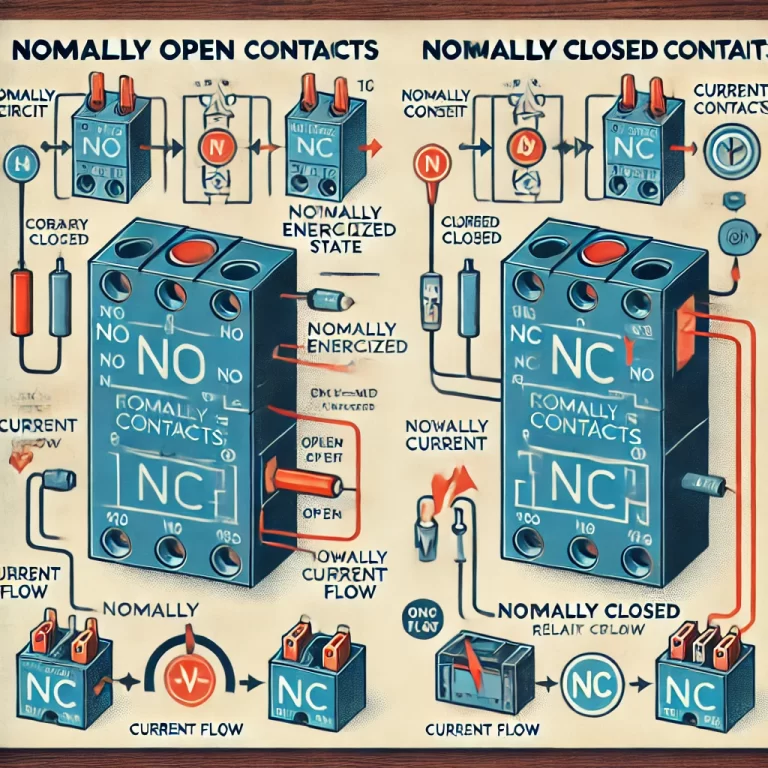

Relays are electromechanical devices that use an electromagnetic field to open or close contacts, controlling the flow of electrical current in a circuit. Key components of a relay include a coil, contacts, and a spring mechanism. When the coil is energized, it generates a magnetic field that moves the contacts, enabling or interrupting the current flow.

Relays are invaluable for:

Converting low-power control signals into high-power switching operations.

Providing electrical isolation between control and load circuits.

Enhancing the flexibility and scalability of automation systems.

However, a critical issue with relays is the generation of electrical arcs. When the relay contacts open or close, especially under load, an arc can form due to the sudden interruption of current. While brief, these arcs can become ignition sources in explosive environments, presenting a significant safety hazard.

Can Relays Be Used in Intrinsic Safety Circuits?

Given that relays can produce arcs, their compatibility with intrinsic safety circuits is not straightforward. Standard relays are generally unsuitable for IS circuits because:

Arc Energy: The energy from arcs often exceeds the thresholds defined by IS standards, undermining the circuit’s safety integrity.

Fault Conditions: Relay failures can introduce energy spikes, posing additional risks.

The solution lies in using intrinsically safe relays specifically designed for such environments. These relays meet stringent safety standards and incorporate features that mitigate safety risks.

Characteristics of Intrinsically Safe Relays

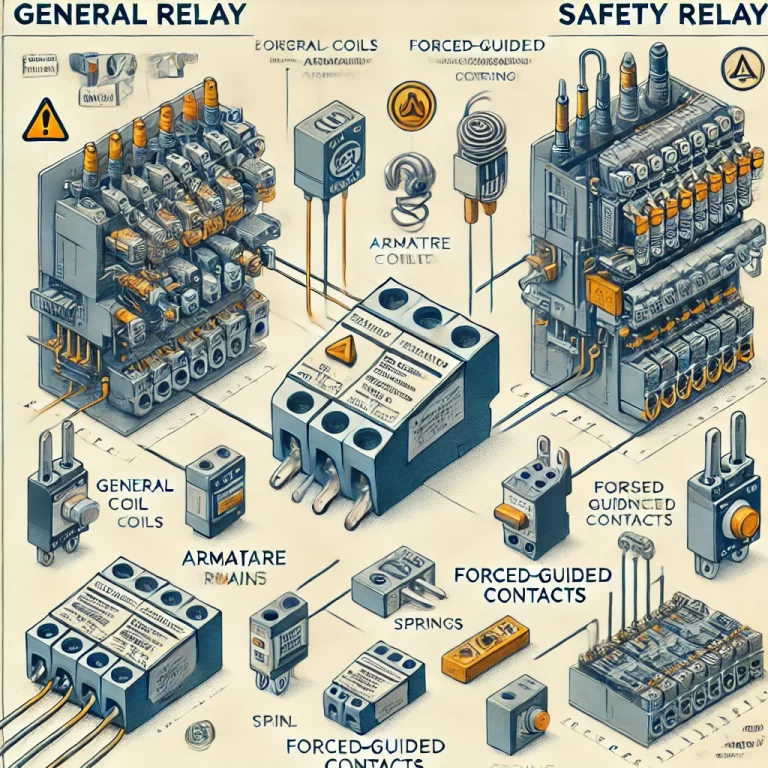

Intrinsically safe relays address the limitations of standard relays through the following characteristics:

Low-Power Design: The coil and switching mechanisms of IS relays consume minimal power, ensuring they do not overload IS circuits.

Electrical Isolation: IS relays often include robust isolation methods to separate control and load circuits, preventing fault propagation.

Arc Suppression: These relays are engineered to minimize or eliminate arcing during contact operation, often using sealed enclosures or advanced contact materials.

Compliance with Standards: IS relays are certified under international safety standards such as ATEX, IECEx, or UL, ensuring their suitability for hazardous environments.

Practical Integration of Intrinsic Safety and Relays

The successful integration of IS circuits with relays requires attention to detail and the implementation of supplementary measures:

Signal Isolation: Using devices like signal isolators ensures that high-energy control signals do not interfere with the IS circuit. These isolators act as barriers, maintaining the low-energy integrity of IS circuits.

Protective Components: Incorporating components such as current-limiting resistors and overvoltage protection devices can help manage fault conditions and prevent energy surges.

System-Level Design: The entire system, including relays, should be evaluated as a whole to ensure that all components contribute to maintaining intrinsic safety.

Conclusion

Relays can be used in intrinsic safety circuits, but only under strict conditions and with the appropriate selection of components. Traditional relays are unsuitable due to the risks posed by arcing and energy spikes. Intrinsically safe relays, with their low-power design, isolation features, and compliance with safety standards, provide a reliable solution.

For successful implementation, engineers must ensure proper system design and use additional measures like signal isolation and protective components. Understanding the interplay between intrinsic safety and relays is essential for creating secure, efficient systems in hazardous environments. By following these guidelines, industries can leverage the benefits of relays without compromising safety.