Selecting the right temperature transmitter is critical to ensuring accurate and reliable temperature measurements in various industrial and commercial applications. This guide provides a detailed overview of the parameters to consider and the steps involved in the selection process.

1. Key Parameters for Selection

1.1 Measurement Range

Choose a transmitter with a measurement range that matches the expected temperature range in your application.

For instance, applications in extreme environments may require ranges exceeding -200°C to 1200°C, while standard environments typically operate within -50°C to 150°C.

1.2 Accuracy

Determine the precision required for your application. Common accuracy levels include ±0.1°C, ±0.5°C, or ±1°C.

For high-precision applications, such as laboratory settings, opt for devices with higher accuracy specifications.

1.3 Output Signal

Select a transmitter based on the required signal output for compatibility with your control system.

4-20 mA: Widely used for long-distance signal transmission.

0-10 V: Common in short-distance and simple systems.

1.4 Sensor Type

Thermocouples: Suitable for wide temperature ranges (e.g., Type K or Type N for high-temperature processes).

RTDs (Resistance Temperature Detectors): Ideal for high-accuracy measurements in lower temperature ranges, such as PT100 or PT1000 sensors.

1.5 Environmental Adaptability

Explosion-Proof Rating: If used in hazardous environments (e.g., oil and gas), ensure compliance with ATEX or similar standards.

Protection Rating: Match the device’s protection rating to the environmental conditions. For example:

IP65: Resistant to dust and low-pressure water jets.

IP67: Suitable for temporary immersion in water.

1.6 Installation Method

Choose an installation method based on site conditions:

Threaded Connection: Common in compact installations.

Flanged Connection: Preferred for high-pressure systems.

Insertion-Type: Ideal for quick and easy maintenance.

1.7 Electrical Connection

Select appropriate electrical connectors based on site requirements:

Screw Terminals: Secure and reliable for fixed installations.

Quick Connectors: Facilitate fast and easy wiring changes.

1.8 Certifications and Standards

Ensure the transmitter complies with relevant certifications and standards, such as:

CE: Required for European markets.

EX: Necessary for explosion-proof environments.

Verify compliance with national or industry-specific standards.

1.9 Brand and After-Sales Support

Opt for reputable brands to ensure product quality, stable performance, and reliable after-sales service.

Consider brands with a proven track record in your industry.

2. Steps for Selection

Step 1: Needs Assessment

Define the requirements for the temperature measurement process:

Medium to be measured.

Temperature range and precision requirements.

Environmental conditions (e.g., humidity, dust, corrosive agents).

Step 2: Market Research

Compare technical specifications and pricing from various manufacturers.

Look for models with features matching your application needs.

Step 3: Sample Testing

Request product samples and perform on-site tests under actual operating conditions.

Evaluate performance metrics such as response time, stability, and accuracy.

Step 4: Supplier Evaluation

Assess the supplier’s capability in terms of:

Manufacturing quality.

Customer service and technical support.

Warranty and service options.

Step 5: Cost Analysis

Account for total costs, including:

Purchase price.

Installation and integration costs.

Maintenance and calibration expenses.

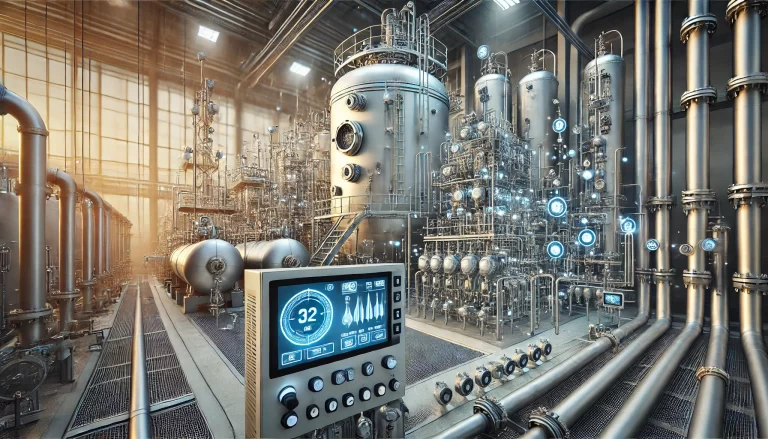

3. Practical Example

Scenario: Selecting a Temperature Transmitter for a Chemical Plant

Requirements:

Medium: Corrosive chemicals.

Range: -50°C to 300°C.

Accuracy: ±0.1°C.

Solution:

Choose an RTD-based transmitter with a PT100 sensor.

Ensure a protective housing with an IP67 rating and explosion-proof certification.

Opt for a 4-20 mA signal output to integrate with the plant’s control system.

Select a brand known for its robust after-sales service.

By following these guidelines and considerations, you can confidently select a temperature transmitter that meets your technical and operational requirements. Proper selection ensures enhanced system performance, reduced maintenance, and improved measurement reliability.