Relays are essential components in electrical and industrial control systems. They act as electrically operated switches, enabling low-power circuits to control high-power systems. Among the types of relays, general relays and safety relays are commonly used, each serving distinct purposes. This article delves into their principles, characteristics, and differences in detail.

General Relays

Principles of Operation

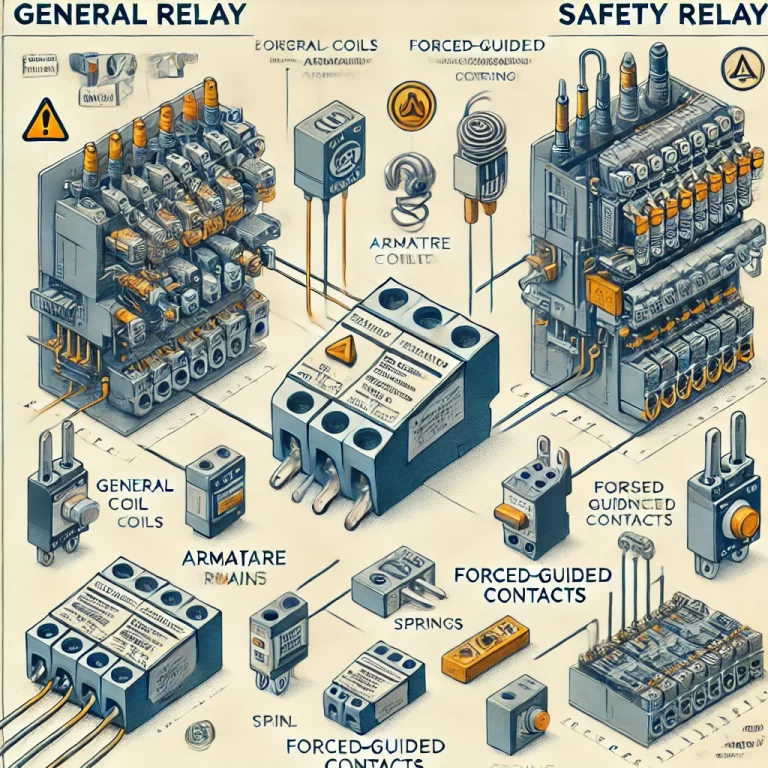

A general relay operates based on electromagnetic induction. When an electrical current passes through its coil, a magnetic field is generated. This magnetic field attracts a movable armature (or contact lever), causing the relay’s contacts to either open or close. Once the current is interrupted, the magnetic field disappears, and a spring returns the armature to its original position.

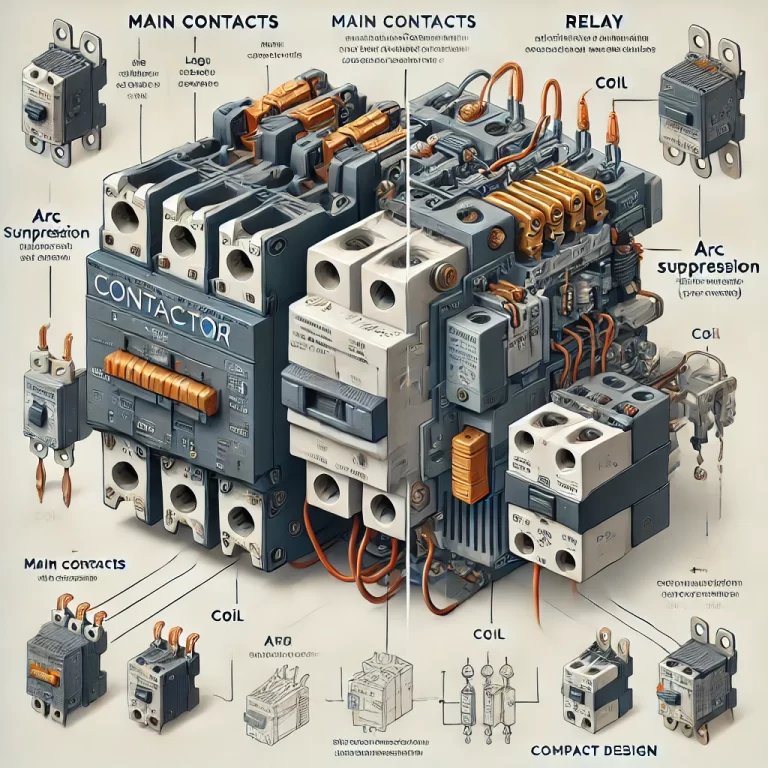

Key Components:

- Coil: Generates a magnetic field when current flows through it.

- Armature: A movable iron piece that responds to the magnetic field.

- Contacts: Switch points that change states (open/close) depending on the armature’s movement.

- Spring: Restores the armature to its default position when the coil is de-energized.

Characteristics of General Relays

- Simplicity: The structure is straightforward, making them cost-effective and easy to use.

- Versatility: They are available in various sizes and configurations for different voltage and current ranges.

- Applications: Widely used in control systems for lights, motors, and other appliances.

- Reliability: While reliable under normal conditions, they are not designed for fail-safe operations in high-risk scenarios.

Safety Relays

Principles of Operation

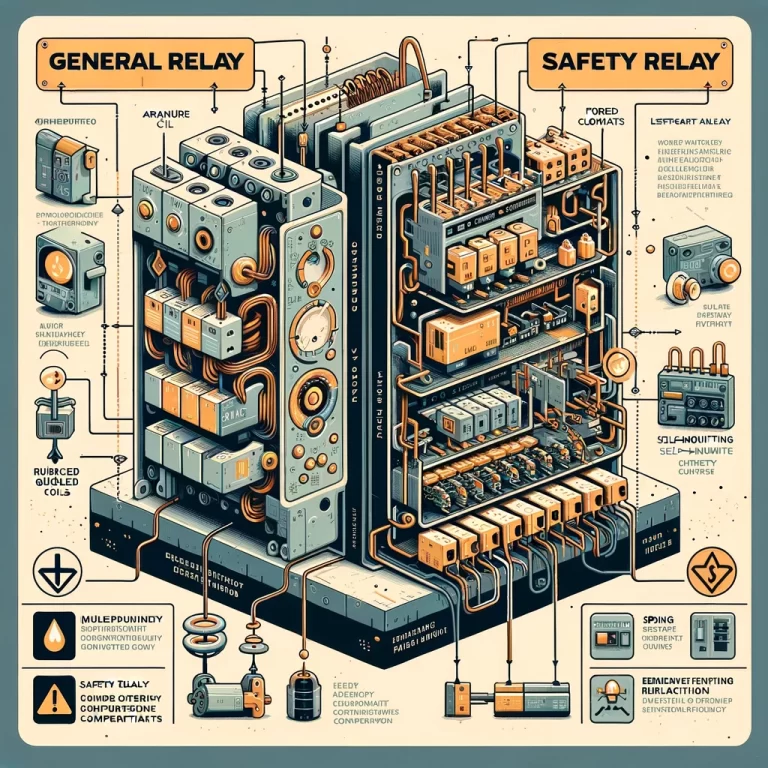

Safety relays are designed to provide fail-safe operation in critical systems. They incorporate advanced features such as redundancy, self-monitoring, and fault detection to ensure that even in the event of a failure, the system remains safe. While the basic principle of using electromagnetic induction remains the same as general relays, safety relays include additional mechanisms to enhance reliability and ensure safety compliance.

Unique Features:

- Redundancy: Often, multiple coils and contacts are employed to ensure backup functionality.

- Forced-Guided Contacts: The contacts are mechanically linked to ensure that if one contact fails, the others remain in a predictable and safe state.

- Self-Monitoring: The relay checks its own operation for issues like coil failure or contact welding.

- Fault Tolerance: Designed to enter a safe state in case of internal or external faults.

Characteristics of Safety Relays

- High Reliability: Ensures operational safety even in adverse conditions.

- Compliance: Conforms to stringent international safety standards such as ISO 13849 or IEC 62061.

- Application: Used in systems where human safety or critical operations depend on uninterrupted control.

- Cost: More expensive than general relays due to their advanced features.

Key Differences Between General Relays and Safety Relays

| Aspect | General Relay | Safety Relay |

|---|---|---|

| Primary Function | General control of circuits. | Ensuring safety in critical systems. |

| Structural Complexity | Simple design. | Complex with redundant and self-monitoring features. |

| Response to Faults | May fail unpredictably. | Designed to fail in a safe and controlled manner. |

| Contact Design | Standard contacts. | Forced-guided contacts for fault transparency. |

| Applications | Routine circuit switching tasks. | Emergency stop, safety doors, and hazardous equipment control. |

| Standards Compliance | No specific safety standards. | Must meet rigorous safety regulations. |

| Cost | Low. | Higher due to specialized safety features. |

Applications of Each Type of Relay

General Relay Applications

- Lighting Control: Used in household and commercial lighting systems.

- Motor Control: Commonly used for starting and stopping motors in industrial machines.

- Automation Systems: Provides control in non-critical systems like HVAC or irrigation systems.

Safety Relay Applications

- Emergency Stop Systems: Ensures safe disconnection of power during emergencies.

- Safety Doors: Monitors and controls access to hazardous areas in machinery.

- Critical Process Controls: Used in scenarios like robotic arms or industrial presses where operator safety is paramount.

Why Choose a Safety Relay?

- Human Safety: Designed to protect human lives by ensuring machines stop or remain in a safe state during malfunctions.

- Regulatory Compliance: Mandatory in many industries to meet international safety standards.

- Reliability: Provides peace of mind in high-risk environments by minimizing the possibility of failure.

Conclusion

The choice between general and safety relays depends on the application’s safety and reliability requirements. While general relays are sufficient for routine electrical control tasks, safety relays are indispensable in environments where human safety and system reliability are paramount. Understanding their principles and differences ensures the appropriate relay is selected for every application.