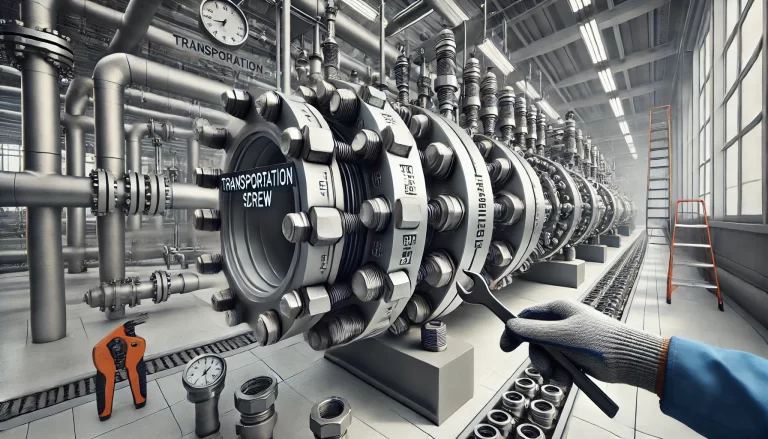

Pipe expansion joints are essential components in piping systems, designed to absorb thermal expansion, contraction, and other mechanical movements. A common question arises when dealing with the external screws (often called transportation bolts or limit rods) on these joints: should they be removed, or should the nuts be tightened during installation and operation? The answer depends on their purpose and the design of the expansion joint. Below is a detailed guide to understanding and handling these screws.

1. Purpose of External Screws on Expansion Joints

External screws on expansion joints serve different purposes, depending on their design and application. Common functions include:

Transportation Lock:

- These screws are often installed by the manufacturer to prevent the expansion joint from being deformed during shipping and handling.

- They temporarily hold the joint in its manufactured position, ensuring safety and structural integrity before installation.

Limit Rods:

- In some designs, external screws act as limit rods, restricting the maximum movement of the expansion joint.

- These rods protect the joint from excessive compression or elongation that might occur due to pressure surges or misalignment in the piping system.

Pressure Testing:

- In certain cases, the screws are tightened temporarily to lock the joint during hydraulic or pneumatic pressure testing. This prevents the joint from absorbing test-induced movements.

2. Do the Screws Need to Be Removed?

Whether these screws should be removed depends on their purpose:

Transportation Screws:

- Typically Removed: If the screws were installed purely for transportation purposes, they must be removed after the expansion joint is securely installed in the pipeline. This allows the joint to perform its function—compensating for movement and thermal expansion.

Limit Rods:

- Usually Retained: If the screws are designed to serve as limit rods, they should not be removed. Instead, the nuts on these screws may need to be adjusted to ensure the rods are neither too loose nor too tight, allowing the joint to move within its designed range.

3. Should the Nuts Be Tightened?

The degree to which the nuts on the screws should be tightened depends on the type of screws and the operational requirements of the expansion joint:

For Limit Rods:

- Adjust, Do Not Over-Tighten: Limit rods are typically equipped with nuts that need to be adjusted to provide the necessary movement range for the expansion joint. Tightening the nuts too much can prevent the joint from moving as intended, while leaving them too loose can risk excessive movement or failure under pressure.

- Refer to Manufacturer Specifications: Always follow the manufacturer’s guidelines for the exact clearance or torque required for the nuts.

For Transportation Screws:

- Tightened During Transport, Loosened After Installation: If the screws are there solely for transportation, they should be securely tightened during shipping but fully removed once the joint is installed.

4. Steps for Handling External Screws

To properly handle external screws on a pipe expansion joint:

Consult the Manufacturer’s Manual:

- The manual will provide specific instructions regarding the screws, including whether they should be removed, retained, or adjusted.

Inspect the Screws Before Installation:

- Check the condition of the screws to ensure they are not damaged or corroded during transport or storage.

Adjust or Remove Based on Function:

- If they are transportation screws, remove them once the joint is installed.

- For limit rods, adjust the nuts to provide proper movement clearance as specified.

Pressure Testing (If Applicable):

- During hydraulic or pneumatic pressure testing, the screws may need to be temporarily tightened to lock the joint. After testing, adjust or remove them as required for operation.

Recheck After Installation:

- Ensure all screws are correctly adjusted or removed, and confirm the expansion joint can move freely within its design limits.

5. Potential Risks of Improper Handling

Failure to handle external screws properly can lead to:

- Restricted Movement: If transportation screws are not removed, the expansion joint will not function as intended, potentially leading to excessive stress on the pipeline.

- Excessive Movement: If limit rods are removed or improperly adjusted, the joint may move beyond its design limits, risking rupture or damage.

- Reduced Lifespan: Improper handling can accelerate wear and tear on the joint, reducing its operational lifespan.

6. Conclusion

External screws on pipe expansion joints play a vital role during transportation, installation, and operation. Understanding their purpose and following proper handling procedures is critical to ensuring the joint functions as designed. Always consult the manufacturer’s documentation and involve qualified professionals if uncertainties arise. By doing so, you can prevent equipment failures, extend the lifespan of the expansion joint, and maintain the integrity of the piping system.