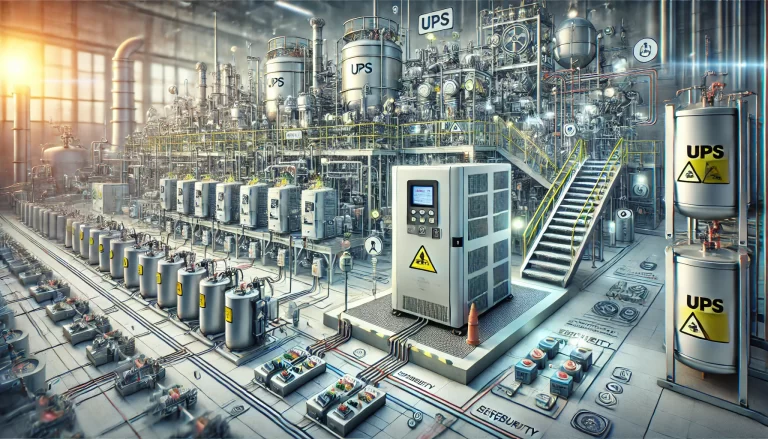

In industrial environments, critical systems such as Safety Instrumented Systems (SIS), Distributed Control Systems (DCS), and Gas Detection Systems (GDS) play a vital role in ensuring safety, reliability, and operational efficiency. A key aspect of maintaining the robustness of these systems is the provision of Uninterruptible Power Supply (UPS). Whether the UPS for these systems should be independent or shared is a significant design consideration. Below, we delve into the reasoning, standards, and best practices surrounding the independence of UPS in these systems.

1. Overview of SIS, DCS, and GDS

SIS (Safety Instrumented System): SIS is designed to detect abnormal conditions and bring the process to a safe state automatically. It is the last line of defense in preventing catastrophic failures. For this reason, it requires the highest level of reliability and fault tolerance.

DCS (Distributed Control System): DCS handles process control, including managing production parameters and optimizing efficiency. While less critical than SIS from a safety perspective, the failure of a DCS can lead to significant downtime and economic losses.

GDS (Gas Detection System): GDS monitors potentially hazardous gases and provides alerts to prevent risks to personnel and the environment. It is critical for early hazard detection, especially in industries dealing with flammable or toxic gases.

2. Why UPS Independence is Essential

Eliminating Shared Failure Points: A shared UPS introduces a single point of failure. If the UPS fails, all connected systems will lose power, potentially leading to safety incidents, production downtime, or undetected gas leaks.

Prioritizing Safety: SIS, being a safety-critical system, must function independently of DCS and GDS. An issue in the power supply to DCS or GDS should not compromise the functionality of SIS, which directly protects lives and prevents environmental disasters.

Minimizing Risk of Cascading Failures: Power anomalies in one system (e.g., a power surge or overload in DCS) should not propagate to other systems like SIS or GDS. Independent UPS configurations ensure electrical isolation, mitigating such risks.

3. Standards and Regulations

IEC 61508/61511 (Functional Safety Standards): These international standards emphasize the reliability and independence of SIS, including power supply considerations. They recommend designing SIS to remain operational even under severe fault conditions, which includes using an independent UPS.

Industry Best Practices: In sectors such as oil and gas, pharmaceuticals, and petrochemicals, it is common to see SIS, DCS, and GDS powered by separate UPS systems. This design approach aligns with risk management and regulatory compliance.

4. Detailed Design Considerations

a. SIS UPS Requirements

- Full Independence: The UPS for SIS must be completely independent to ensure it can continue to power safety-critical functions during power outages or disturbances.

- High Reliability: Redundant UPS configurations (e.g., N+1 or 2N) are often employed to further enhance reliability.

- Integration with Emergency Power: The SIS UPS should be connected to an emergency power source, such as a diesel generator, for extended autonomy during prolonged power losses.

b. DCS UPS Requirements

- Selective Independence: While DCS may share UPS with GDS in some cases, it is often better to use a separate UPS to reduce complexity and risks.

- Capacity and Redundancy: The UPS should be sized to handle the full load of the DCS with some redundancy to account for unexpected demand spikes or failures.

c. GDS UPS Requirements

- Isolation from SIS: GDS must not share a UPS with SIS to ensure that gas monitoring remains unaffected by SIS or DCS malfunctions.

- Robustness in Harsh Environments: The UPS for GDS should be designed to function reliably in hazardous or explosive environments, where gas detection is critical.

5. Risk Assessment and Decision-Making

For each specific installation, a detailed risk assessment should be conducted to determine whether DCS and GDS can share a UPS. Factors to consider include:

- System Criticality: Prioritize independence for systems with higher safety and operational impact.

- Environmental Conditions: Harsh environments may necessitate separate UPS systems for better reliability.

- Economic Trade-Offs: While independent UPS systems are more expensive, the potential cost of downtime or incidents often justifies the investment.

6. Maintenance and Monitoring

- Regular Testing: All UPS systems must be regularly tested under load conditions to ensure functionality during actual power outages.

- Battery Health Monitoring: Batteries are a critical component of any UPS. Their health should be closely monitored, and replacements made proactively.

- Alarm and Notification Systems: UPS systems should be integrated with monitoring systems to provide alerts in case of faults or capacity issues.

7. Conclusion

To maximize safety, reliability, and operational efficiency, it is highly recommended that SIS, DCS, and GDS have independent UPS systems. While DCS and GDS may share a UPS in low-risk scenarios, SIS should always have a fully independent power source. Following international standards, industry best practices, and a thorough risk assessment ensures that these systems can function seamlessly, even during power disruptions.

By prioritizing the independence of UPS systems for critical industrial applications, organizations can significantly reduce risks, enhance safety, and protect both personnel and assets.