As cold weather approaches, chemical plants must implement robust anti-freezing and anti-condensation measures to ensure safe production and prevent equipment malfunction. Freezing can lead to blockages, ruptures, and hazardous conditions if not properly managed. Below is an in-depth guide to essential anti-freezing measures for chemical plants:

1. Insulation for Equipment and Pipelines

- Selecting Insulation Materials: Use high-quality insulation materials like fiberglass, foam, or composite materials tailored to the specific needs of chemical equipment. These materials should be water-resistant and durable under both temperature fluctuations and chemical exposure.

- Insulating Vulnerable Areas: Special attention should be given to sections most vulnerable to freezing, such as bends, valves, and flanges in pipelines. These areas are more susceptible to temperature drops and can quickly become a bottleneck. Increase the insulation thickness or install protective covers in these critical spots to ensure thorough protection.

- Routine Insulation Checks: Inspect insulation layers periodically to detect wear, gaps, or damage and replace them if necessary. This regular upkeep helps maintain insulation efficacy, especially in key sections.

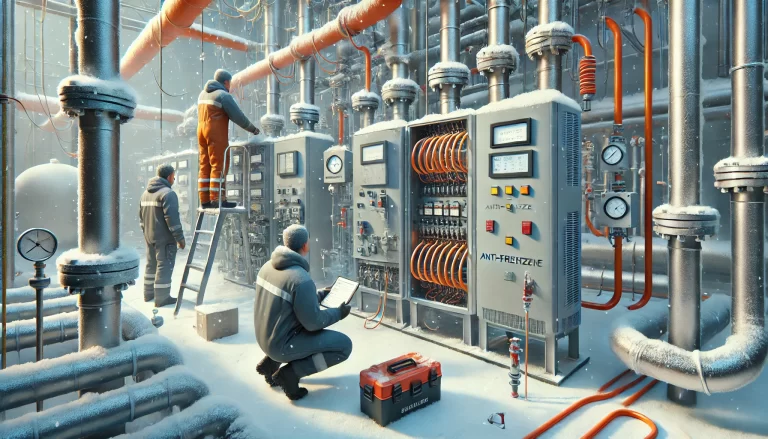

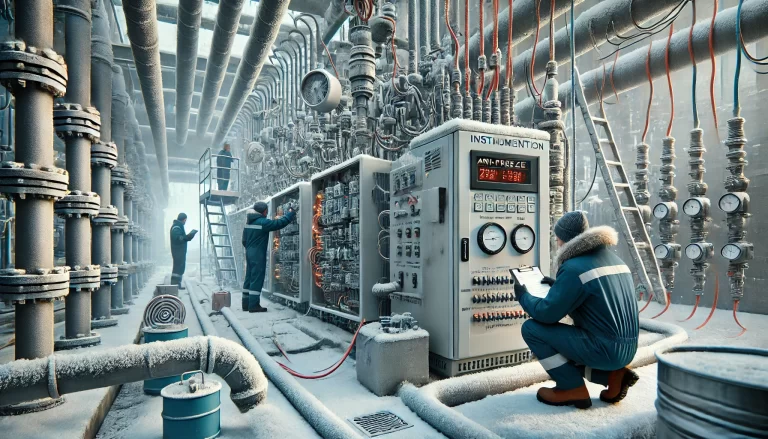

2. Electrical Heat Tracing System

- Installing Electric Heat Tracing: For critical pipelines and equipment prone to freezing, electric heat tracing (EHT) cables can maintain the temperature above freezing. These cables run along pipelines and prevent liquid from solidifying by emitting controlled heat.

- Calibrating Temperature Controls: EHT systems should have well-calibrated thermostats or control units that prevent overheating or inadequate heating. Setting the proper activation temperatures ensures that pipes remain warm without risking excess energy consumption or overheating.

- Redundancy and Monitoring: Consider installing a monitoring system to alert personnel if the heat tracing system fails, so any issues can be promptly addressed.

3. Drainage and Water Removal in Pipelines

- Regular Drainage: Ensure periodic drainage of water from pipes, especially in steam pipelines where condensation tends to accumulate. Stagnant water can freeze in low temperatures, leading to blockages and potential damage.

- Installing Drain Valves: Place drain valves at low points or where condensation gathers. Automatic drain valves can be beneficial, as they continuously discharge water, ensuring that the system remains dry and free from freezing risks.

- Manual Inspections: Even with automatic systems in place, regular manual inspections are necessary, particularly during temperature drops, to check for residual water or possible clogs.

4. Use of Antifreeze Solutions

- Choosing Appropriate Antifreeze: In water-based systems or circulating fluids, adding antifreeze, such as glycol solutions, can significantly lower the freezing point. Select antifreeze solutions compatible with the materials in use to avoid corrosion or chemical reactions.

- Concentration Adjustment: The concentration of antifreeze should be adjusted according to predicted weather conditions and system requirements. Too low a concentration will be ineffective, while too high can increase system pressure and reduce efficiency.

- Regular Sampling and Testing: Test antifreeze solutions periodically to ensure they maintain effectiveness and adjust as needed. This routine also helps detect possible contamination that could affect the system’s stability.

5. Routine Pipeline and Equipment Inspections

- Temperature Monitoring: Install temperature sensors to monitor conditions in pipelines and equipment, especially in colder months. Real-time monitoring allows early detection of low-temperature risks and enables a swift response.

- Manual Inspection Rounds: Assign personnel to conduct regular rounds of manual inspections, focusing on critical areas and high-risk spots where temperatures are likely to drop faster. Inspection frequencies should increase during colder weather or when freezing conditions are imminent.

- Documentation of Inspections: Keep records of each inspection and log any adjustments made or areas of concern. This history helps in assessing patterns and making improvements to freeze prevention measures.

6. Backup Heating Sources and Emergency Response Plans

- Standby Heating Equipment: Have backup heating equipment such as space heaters, hot air blowers, or portable heating units ready in case of severe temperature drops or emergencies. These can quickly warm pipelines and equipment as a temporary solution.

- Emergency Action Plans: Prepare and train teams on emergency protocols for extreme cold conditions. The plan should include steps to follow in case of freezing in critical systems, such as immediate shutdowns, rerouting, or temporary heating solutions.

- Conducting Drills: Regular drills should be conducted to ensure that personnel are familiar with emergency procedures and can respond efficiently under cold-weather scenarios.

7. Preventive Measures for Idle or Out-of-Service Equipment

- Draining Systems: If equipment or systems are to remain unused for an extended period, drain all fluids to prevent freezing and expansion damage. Completely empty tanks, pipes, and other containers to avoid potential ruptures from residual water freezing.

- Closing Valves and Inlets: Ensure that all valves, vents, and inlets connected to inactive equipment are securely closed to prevent cold air from entering and causing internal freezing.

- Periodic Checks on Idle Equipment: Even when out of use, equipment should be periodically inspected to ensure that no environmental conditions have led to freezing or leaks.

8. Employee Training and Awareness Programs

- Cold Weather Operations Training: Train employees on specific anti-freeze and anti-condensation protocols, including the correct use of insulation, antifreeze application, and electric heat tracing. Ensure that they understand how to handle equipment in cold conditions safely.

- Raising Awareness on Cold Safety: Educate employees on the potential hazards associated with cold weather, such as slip risks from icy surfaces or exposure to extreme temperatures, which can affect both safety and productivity.

- Regular Refresher Courses: Conduct periodic refresher courses to keep safety protocols top of mind and integrate lessons learned from previous cold seasons.

By systematically implementing these preventive measures, chemical plants can effectively reduce the risk of production downtime, equipment damage, and safety hazards caused by freezing temperatures. Planning and preparation are essential, and by staying proactive, plants can operate safely and efficiently even in extreme winter conditions.