The insertion depth of a temperature sensor refers to how deeply the sensor’s probe is inserted into the medium being measured. This parameter plays a critical role in ensuring accurate and reliable temperature measurements. The optimal insertion depth can influence both the precision of the temperature readings and the sensor’s response time. Several factors need to be considered when determining the correct insertion depth, as outlined below.

1. Accuracy and Stability of Measurements

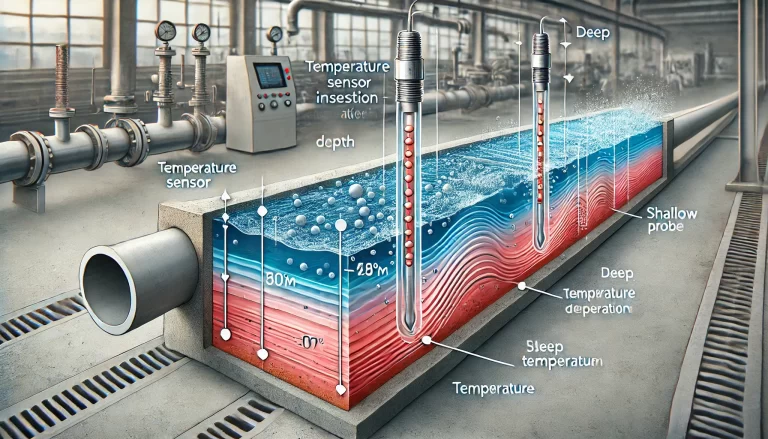

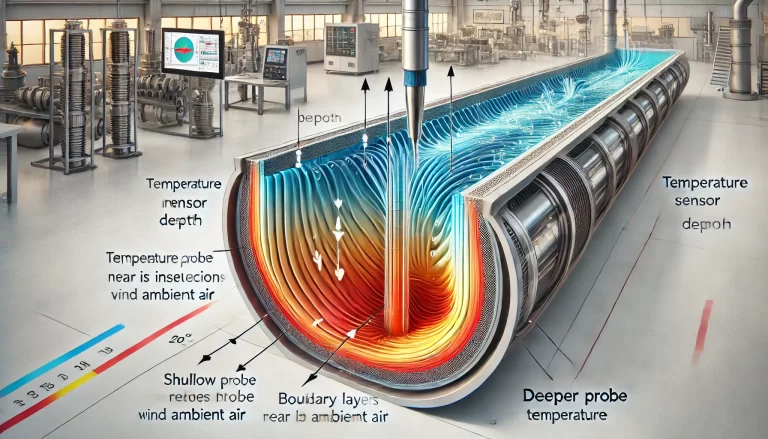

- Shallow Insertion: If the temperature sensor probe is inserted too shallowly, it may not reflect the true temperature of the medium. Surface temperatures are more likely to be influenced by external environmental factors, which can distort readings. For instance, ambient air temperature, radiative heat transfer, or proximity to other heat sources can cause discrepancies, making the temperature reading inaccurate.

- Excessive Depth: Conversely, if the probe is inserted too deeply, the measurement could also suffer inaccuracies, particularly in fluid systems. In such cases, deeper insertion could lead to variations in the readings due to turbulence, flow dynamics, or thermal stratification within the fluid.

2. Thermal Response Time

- Shallow Insertion and Quick Response: A shallow insertion often leads to a faster thermal response, meaning that the sensor reacts more quickly to temperature changes. However, this may come at the cost of measurement stability, as shallow probes are more exposed to external influences.

- Deep Insertion and Delayed Response: With a deeper insertion, the sensor might have a slower response time to temperature fluctuations. The longer response time occurs because the sensor needs more time to reach thermal equilibrium with the medium. However, once it stabilizes, the reading will typically be more accurate and less susceptible to external interference.

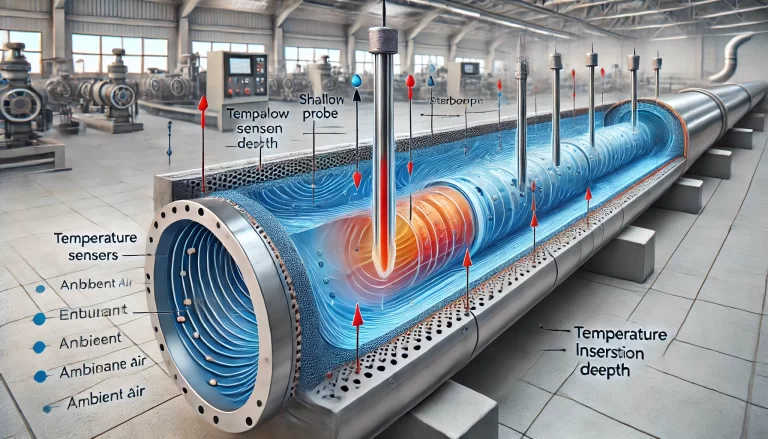

3. Influence of Fluid Dynamics

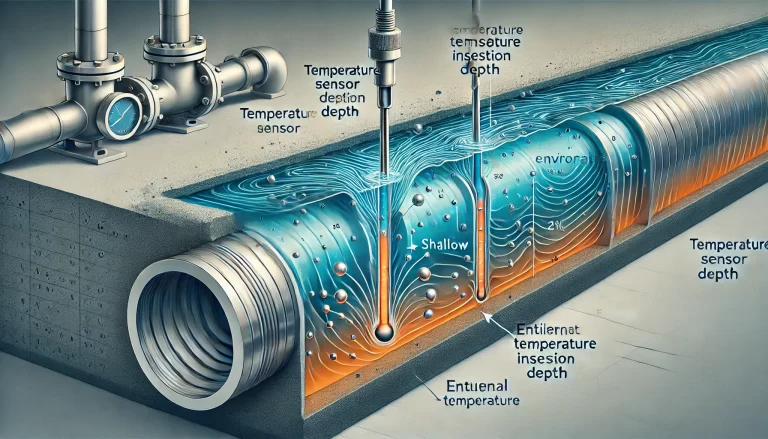

In scenarios involving fluid flow, such as in pipelines or open-channel flows, the insertion depth is critical for obtaining a representative temperature of the fluid:

- Shallow Insertions in Flowing Fluids: A shallowly inserted probe in a flowing fluid may only measure the temperature of the boundary layer, which is the thin layer of fluid close to the wall of the pipe. This region may not accurately represent the bulk temperature of the fluid because the flow may be slower or experience different thermal conditions near the boundary.

- Recommended Insertion Depth in Flowing Fluids: In practical applications, it’s often recommended that the insertion depth should be at least one-third to one-half of the pipe’s diameter. This ensures that the sensor is sufficiently immersed in the flow to measure the average temperature across the fluid’s cross-section. By avoiding the boundary layer, the sensor can provide a more accurate representation of the fluid’s overall temperature.

4. Environmental and Installation Considerations

The installation environment can also affect the optimal insertion depth:

- Ambient Temperature Influence: In environments with significant temperature gradients or strong radiative heating, the sensor’s proximity to external surfaces (such as walls or heat sources) can distort the measurement. Ensuring sufficient insertion depth will minimize this interference by isolating the sensor probe from these external factors.

- Installation Position: The location and orientation of the sensor in the system should be carefully chosen. Horizontal and vertical installations may demand different insertion depths based on factors like fluid stratification, buoyancy-driven flow patterns, or heat convection.

5. Standards and Guidelines for Insertion Depth

Industry standards and best practices offer guidelines for the appropriate insertion depth in different measurement environments:

- Static Medium (Air or Liquid): In non-flowing or static mediums, such as air or still liquid, the sensor’s insertion depth should generally be 15 to 20 times the diameter of the sensor probe. This ensures that the sensor reaches an undisturbed zone of the medium, free from surface effects.

- Flowing Medium (Pipelines or Ducts): For flowing fluids, the sensor should be inserted at least 10 times the probe diameter, though a greater depth might be needed depending on the flow characteristics of the medium. This depth allows the sensor to bypass the thermal boundary layer and reach a region where the temperature distribution is more uniform and representative of the entire flow.

6. Material and Structural Design of the Sensor

The material and structural design of the temperature sensor can also influence the optimal insertion depth:

- Protective Sheaths: In high-temperature or corrosive environments, sensors are often encased in protective sheaths. These protective layers may alter the sensor’s thermal conductivity and response time, meaning that a greater insertion depth might be necessary to achieve accurate measurements. The increased thermal mass of a sheathed sensor may also slow the sensor’s response time, further justifying deeper insertion.

- Sensor Type: Some sensor designs, such as resistance temperature detectors (RTDs) or thermocouples, have specific insertion depth requirements based on their operating principles. RTDs, for instance, generally benefit from deeper insertion due to their sensitivity to surface effects, whereas thermocouples, which measure temperature through voltage differences at the junction of two metals, can be more flexible depending on the application.

7. Influence of Medium Type

The type of medium being measured also plays a role in determining the ideal insertion depth:

- Gases: In gases, particularly those with low thermal conductivity, the insertion depth is crucial because gases tend to have slower heat transfer rates compared to liquids or solids. This makes it essential for the sensor to be deeply inserted into the gas medium to ensure the probe reaches thermal equilibrium with the gas.

- Liquids: In liquids, heat transfer is generally more efficient, so the sensor may require a shorter insertion depth compared to gases. However, factors such as liquid viscosity, flow velocity, and the presence of suspended particles must be considered when determining the optimal insertion depth.

Conclusion

In conclusion, the insertion depth of a temperature sensor is a vital factor that can significantly impact the accuracy, stability, and response time of temperature measurements. A carefully determined insertion depth balances the need for precision, thermal response, and environmental considerations. While shallow insertion can lead to quick responses but compromised accuracy, deep insertion ensures better stability but slower reactions to temperature changes. The choice of insertion depth must therefore account for the characteristics of the medium, the flow dynamics, sensor design, and environmental conditions. By tailoring the insertion depth to the specific measurement context, one can achieve reliable and precise temperature readings in various industrial and scientific applications.