In modern industrial and home automation, relays play a critical role in controlling electrical circuits by opening and closing contacts in response to electrical signals. Relays are essential components that ensure the smooth operation of complex systems, providing safety, efficiency, and reliability. Understanding the various types of relays and their applications is crucial for anyone involved in automation systems.

In this article, we will explore the different types of relays commonly used in automation, their working principles, and the importance of each in the automation landscape.

What is a Relay?

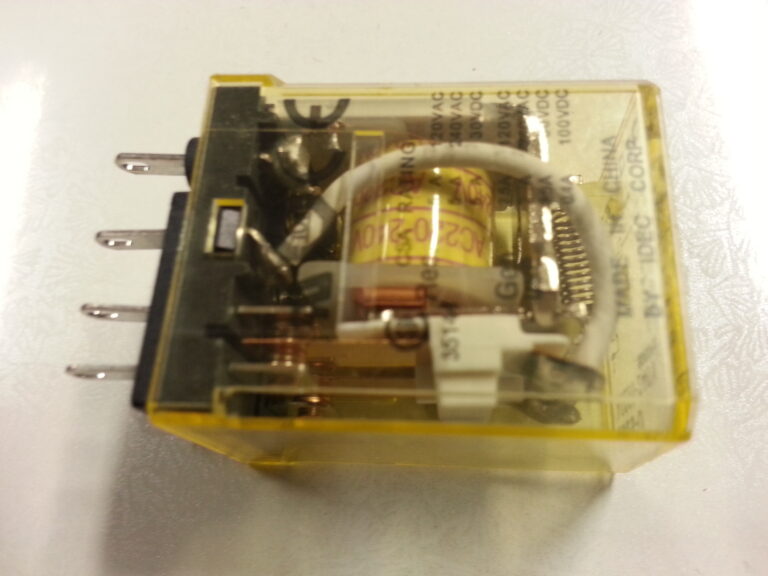

A relay is an electrically operated switch that allows low-power signals to control high-power devices, providing an interface between control systems and electrical circuits.

It operates by using an electromagnet to mechanically control the opening and closing of contacts within the relay. Relays come in various types, each designed for specific applications and operating conditions, including control of motors, lighting systems, heating elements, and more.

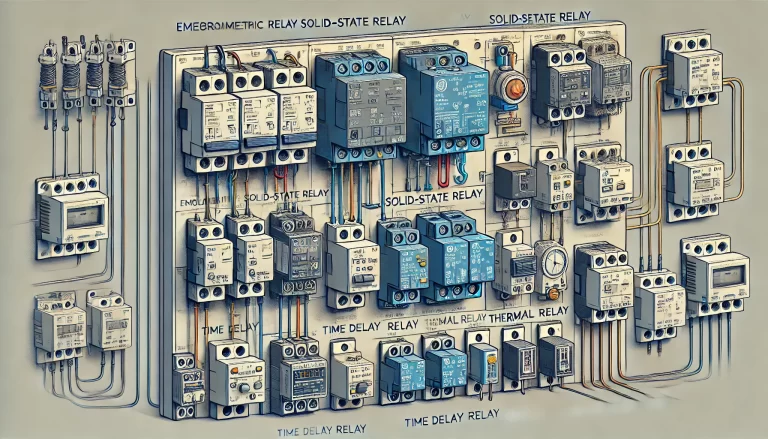

Types of Relays Used in Automation Systems

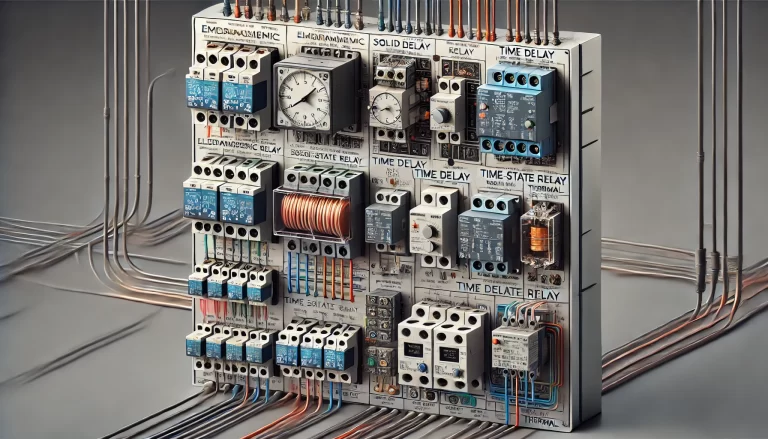

Electromagnetic Relays (EMR)

The electromagnetic relay is the most basic and widely used relay in automation systems. It operates on the principle of electromagnetism. When current flows through a coil, it generates a magnetic field that moves a switch, either opening or closing the contacts. These relays are commonly used in low-voltage control circuits to manage higher voltage systems.

Applications:

- Motor control circuits

- Power distribution systems

- HVAC systems

Advantages:

- Simple design and reliable operation

- Capable of handling high current and voltage levels

Disadvantages:

- Mechanical wear over time

- Slower response compared to solid-state relays

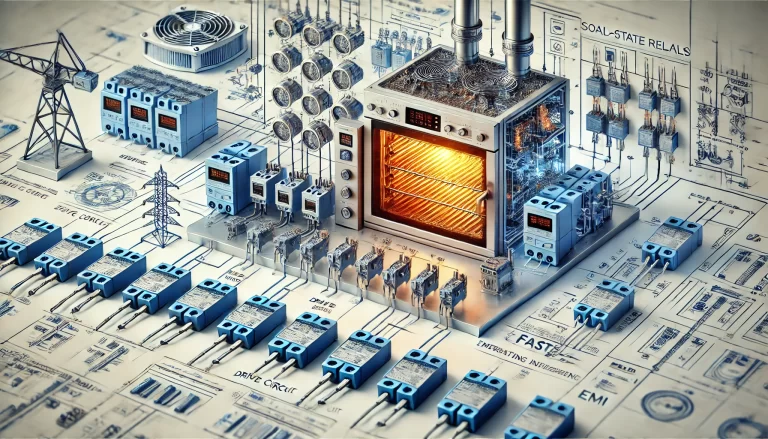

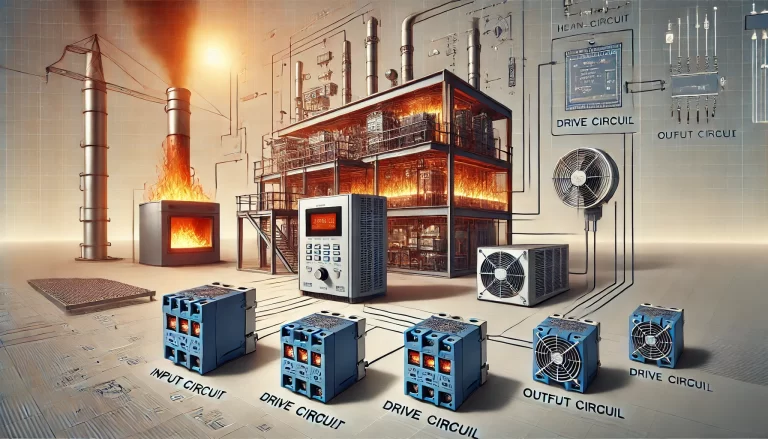

2. Solid State Relays (SSR)

Unlike electromagnetic relays, solid-state relays have no moving parts. They use semiconductor switching elements like transistors, diodes, or thyristors to perform the switching function. Because they have no mechanical components, SSRs are more durable and can operate at faster switching speeds.

Applications:

- Industrial automation systems

- Electronic devices

- Temperature control systems

Advantages:

- Longer lifespan due to no mechanical wear

- Silent operation

- Faster response time

Disadvantages:

- More expensive than electromagnetic relays

- Heat dissipation can be an issue in high-power applications

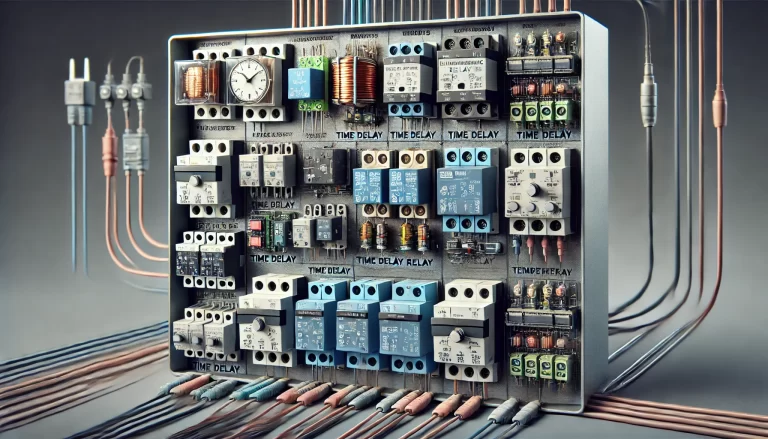

3. Time Delay Relays (TDR)

Time delay relays are designed to open or close contacts after a specified time delay, making them ideal for applications that require a delay in action. These relays are commonly used in automation systems where timing is critical, such as in sequential operations or processes that require a specific delay between tasks.

Applications:

- Conveyor belt systems

- Sequential motor start-up systems

- Lighting control

Advantages:

- Accurate control over timing operations

- Can be customized for specific time delays

Disadvantages:

- Limited use in high-speed automation systems

4. Thermal Relays

Thermal relays use temperature as the primary factor in controlling the operation of the relay. These relays often use a bimetallic strip that bends when heated to either open or close the contacts. Thermal relays are commonly used for overload protection in motors and other electrical equipment.

Applications:

- Motor protection

- Overload protection in electrical circuits

Advantages:

- Effective in protecting equipment from overheating

- Simple and reliable design

Disadvantages:

- Limited to temperature-based control applications

- Slower response compared to other relays

5. Latching Relays

Latching relays, also known as bistable relays, are designed to maintain their position even after the control signal is removed. They require only a brief pulse to change their state and will remain in that state until another pulse is received. This makes them energy-efficient since they don’t require continuous power to hold their position.

Applications:

- Lighting control

- Memory storage in control systems

- Circuit breakers

Advantages:

- Energy-efficient since no power is needed to maintain position

- Suitable for memory-related applications

Disadvantages:

- More complex circuitry compared to standard relays

6. Protective Relays

Protective relays are essential for ensuring the safety of power systems. They detect abnormal conditions such as overcurrent, undercurrent, or voltage imbalances and activate circuit breakers to isolate the faulty section of the system. These relays are crucial in preventing damage to equipment and ensuring the safe operation of electrical systems.

Applications:

- Power distribution systems

- High-voltage electrical grids

- Industrial safety systems

Advantages:

- Enhances system reliability and safety

- Quick response to faults

Disadvantages:

- Requires calibration for accurate protection

- Expensive compared to simpler relays

Why Relays Are Important in Automation

Relays are fundamental components in automation systems for several reasons:

Isolation Between Control and Power Circuits: Relays provide electrical isolation between low-power control circuits and high-power load circuits. This isolation ensures that sensitive control components are protected from high voltage or current surges, preventing damage to the system.

Automation of Processes: Relays enable the automation of complex processes by controlling multiple devices simultaneously. With relays, systems can be programmed to perform sequences of actions without manual intervention, increasing efficiency and reducing the potential for human error.

Safety and Protection: Many relays, such as thermal and protective relays, are designed to safeguard equipment by detecting abnormal conditions and disconnecting power to prevent damage. This function is critical in industrial settings where equipment failure can result in costly downtime or hazardous situations.

Energy Efficiency: Relays such as latching relays require minimal power to maintain their state, contributing to energy-efficient system designs. They can be particularly useful in battery-powered or energy-constrained systems.

Customization and Flexibility: Different relay types allow for a high degree of customization in automation systems. Whether the need is for precise timing (with time delay relays) or overload protection (with thermal relays), there is a relay designed for virtually every requirement.

Conclusion

Relays are indispensable in the world of automation. Whether used for simple on-off control, protection, or time-based operations, they enable systems to function safely and efficiently.

By understanding the various types of relays—such as electromagnetic, solid-state, time delay, thermal, latching, and protective relays—automation professionals can design more reliable and responsive systems. As technology advances, the role of relays continues to expand, integrating with modern digital control systems and playing a pivotal role in the automation of industries worldwide.