Hydrogen is an essential gas with widespread applications in industries ranging from energy production to chemical manufacturing and medical research. Its significance is rapidly increasing due to its role as a clean fuel in the transition towards sustainable energy systems.

However, measuring the flow rate of hydrogen, especially in small amounts, can be challenging. Accurate measurement of small hydrogen flow rates is crucial in many applications, such as fuel cell technology, chemical reactions, and laboratory experiments.

This article discusses the importance of measuring small hydrogen flow rates and the various types of flow meters that are best suited for this purpose.

Why Accurate Hydrogen Flow Measurement Matters

Hydrogen is highly reactive, has low molecular weight, and possesses unique physical properties. These characteristics make it both a valuable resource and a potentially dangerous substance to handle. Precise control and measurement of hydrogen flow are essential in several industries:

- Fuel Cells: Hydrogen is a key fuel in fuel cells, which are used in clean energy systems. Accurately controlling the hydrogen flow rate is critical to ensure efficient energy production and avoid excess consumption.

- Chemical Reactions: In the chemical industry, hydrogen is commonly used in reactions such as hydrogenation and gas-phase catalysis. The precise flow rate of hydrogen must be maintained to optimize the reaction conditions and ensure safety.

- Laboratory Research: Small-scale hydrogen flows are often used in experiments, particularly in material science and energy research. Accurate measurement is needed to obtain reliable and reproducible results.

Due to these critical applications, selecting the right flow meter for hydrogen is essential for safety, efficiency, and cost-effectiveness. But given the unique properties of hydrogen, choosing the right instrument for small flow measurements can be tricky.

Challenges in Measuring Hydrogen Flow

Hydrogen presents specific challenges for flow measurement because of its low density and high diffusivity. Here are some of the key challenges:

- Low Density: Hydrogen is much lighter than most gases, which means that many traditional flow meters may not detect it accurately, especially at low flow rates.

- High Diffusivity: Hydrogen tends to diffuse quickly, which can affect measurement stability, particularly in systems with long tubing or multiple flow points.

- High Reactivity: In some environments, hydrogen can react with materials or components in the flow meter, potentially leading to inaccurate measurements or safety hazards.

These challenges necessitate the use of specialized instruments capable of handling hydrogen’s physical properties while delivering high accuracy, especially at low flow rates.

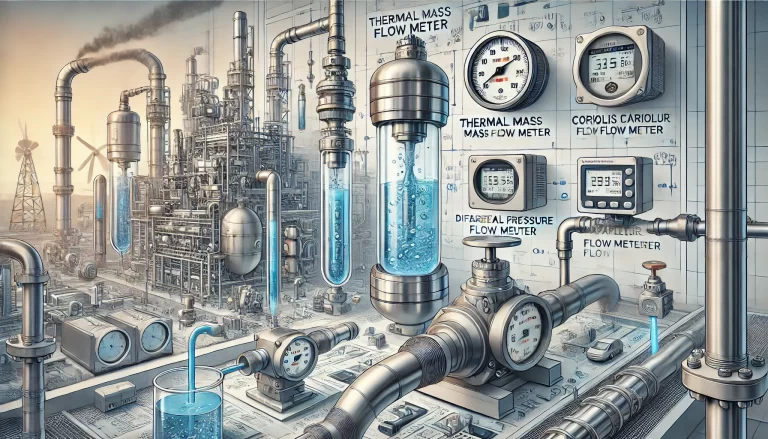

Types of Flow Meters for Small Hydrogen Flow Measurement

To accurately measure small hydrogen flow rates, several types of flow meters are commonly used, each offering distinct advantages. Below are the most effective types for this application:

1. Thermal Mass Flow Meters

Thermal mass flow meters are one of the most widely used instruments for measuring small hydrogen flow rates. These flow meters work by measuring the amount of heat that is absorbed by the gas as it passes over a heated element. Because hydrogen has high thermal conductivity, thermal mass flow meters are well-suited for this application.

- Advantages:

- High sensitivity to low flow rates.

- Direct measurement of mass flow without the need for temperature or pressure compensation.

- Stable and accurate readings even with low-density gases like hydrogen.

- Applications:

- Ideal for applications requiring precision control of hydrogen flow, such as fuel cells, laboratory research, and gas blending systems.

2. Coriolis Mass Flow Meters

Coriolis mass flow meters are another excellent option for measuring small hydrogen flow rates. They operate based on the Coriolis effect, where the mass flow of gas through a vibrating tube creates measurable deflections. These flow meters measure the mass flow rate directly and are not affected by changes in gas density, temperature, or pressure.

- Advantages:

- Extremely accurate, even at very low flow rates.

- Direct measurement of mass flow, providing consistent results.

- Suitable for hydrogen, even in small quantities.

- Applications:

- Used in industries such as chemical processing and fuel cell development where high accuracy is critical.

3. Capillary Flow Meters

Capillary flow meters are designed for extremely low flow rates, making them an excellent choice for small hydrogen flows. These meters use the principle of pressure drop across a small capillary tube to measure flow rates. Due to their design, they can measure minute gas flows with high precision.

- Advantages:

- Very accurate for low flow rates.

- Compact and simple design.

- Minimal maintenance required.

- Applications:

- Common in laboratory settings and experimental setups where the precise measurement of micro-flows is required.

4. Differential Pressure Flow Meters

Differential pressure (DP) flow meters measure the pressure drop across an obstruction in the flow path, such as an orifice or venturi tube, to determine the flow rate. Although traditionally used for larger flow rates, some models are designed for measuring low flow rates, including hydrogen.

- Advantages:

- Robust design, suitable for various gases, including hydrogen.

- Cost-effective for low- to medium-accuracy applications.

- Applications:

- Suitable for industrial processes where moderate accuracy at low hydrogen flows is acceptable.

5. Rotameters

Rotameters, also known as variable area flow meters, measure flow rates by allowing gas to pass through a tapered tube that contains a float. The position of the float within the tube indicates the flow rate. For low hydrogen flow rates, special low-flow rotameters can be used.

- Advantages:

- Simple and visual method of flow measurement.

- Cost-effective for general monitoring.

- Applications:

- Used in applications where precision is less critical, such as basic hydrogen flow monitoring.

Selecting the Right Flow Meter

When selecting a flow meter for small hydrogen flow measurements, several factors must be considered:

- Flow Rate Range: Ensure the chosen flow meter can accurately measure within the expected flow range.

- Precision: The required level of precision will dictate whether a high-end Coriolis or thermal mass flow meter is necessary, or whether a simpler device like a rotameter will suffice.

- Material Compatibility: Hydrogen is highly reactive with certain materials, so selecting a flow meter made from compatible materials is critical to prevent leaks or degradation.

- Cost: Higher precision often comes at a higher cost, so it’s essential to balance the budget with measurement needs.

Conclusion

Measuring small hydrogen flow rates accurately is vital in various industries, from energy to scientific research. Given hydrogen’s unique properties, choosing the right flow meter is essential for ensuring safety, efficiency, and precision in applications.

Thermal mass flow meters, Coriolis meters, capillary flow meters, and differential pressure meters are all strong candidates for this task, each with their strengths. Careful consideration of the specific requirements of the application will help in selecting the most appropriate instrument for measuring hydrogen’s small flow rates.