Working characteristics of vibrating rod level switch

The vibrating rod level switch is an instrument used to detect the height of materials. Its working principle is based on piezoelectric drive and vibration detection.

When the measured medium reaches and partially covers the probe of the vibrating rod switch, the amplitude or frequency of the vibrating probe will be significantly reduced. This change in vibration parameters is detected and analyzed by the intelligent circuit, and a switch signal is output to realize the level detection.

The vibrating rod level switch is suitable for measuring the level of granular solid materials such as sodium hydroxide, lime, cement, sand, soil, coal, dust, flour, sugar, salt, grains, beans, etc.

The influence of probe accumulation and hanging material on the operation of vibrating rod level switch

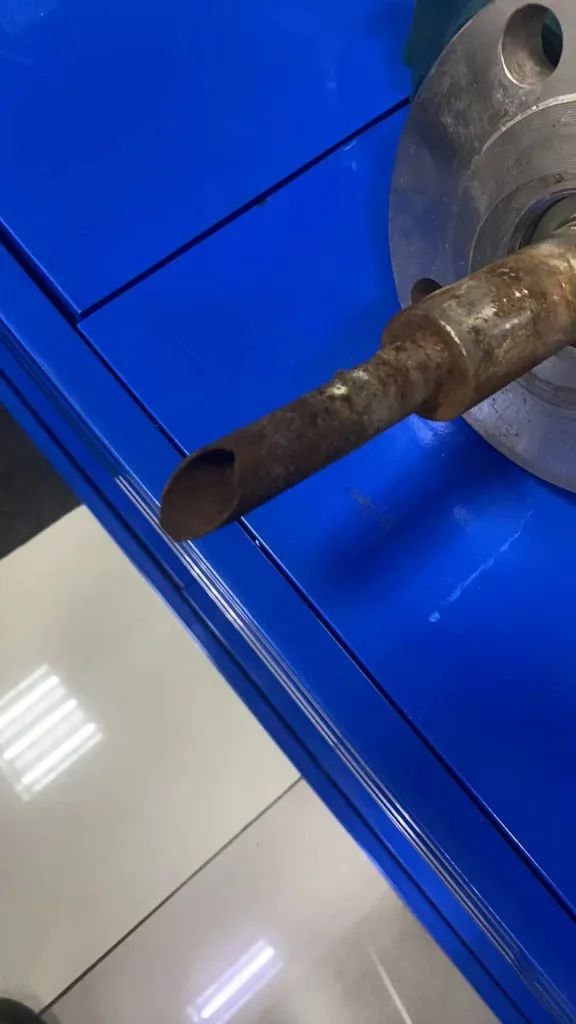

Although the vibrating rod level switch performs well in many applications, the material level switch will be hung to varying degrees on the sensor probe due to the different characteristics of the measured material during long-term operation, and the lumps will not fall off and become part of the probe, causing the vibration of the switch probe to slowly weaken, causing the intelligent analysis detection circuit to mistakenly believe that it has contacted the material and generate a false alarm. When the hanging material is serious, the switch may even work abnormally and fail, resulting in the switch being unable to accurately detect the material height, affecting normal production.

Therefore, in order to maintain the normal operation of the vibrating rod level switch, the accumulated material on the probe must be cleaned regularly to restore the switch to normal operation.

Advantages of vibrating rod level switch over similar switches, advantages of double-tube vibrating rod

Compared with traditional single-tube vibrating rod level switches, our vibrating rod level switch has unique advantages in level detection performance.

Our vibration probe adopts a double-tube design with inner and outer nesting. Driven by piezoelectric devices, the inner and outer tubes resonate at completely consistent resonant frequencies, with small energy loss, making the vibration characteristics of the probe more stable, and the detection accuracy and reliability higher.

At the same time, this double-tube structure also provides higher mechanical strength, strong deformation resistance, higher vibration frequency than similar products, high processing accuracy, improved anti-hanging ability, and longer maintenance cycle than similar products.

At the same time, the probe is designed with anti-corrosion materials, suitable for harsh working conditions, and is widely used in the measurement of various solid granular material levels in petrochemical, pharmaceutical, environmental protection, power plants and other industries.

Regular cleaning of the probe is essential to maintain the normal operation of the vibrating rod level switch.

Accumulated materials on the probe will affect the vibration characteristics of the vibrating rod, causing false alarms or failures, and increasing maintenance costs.

Our vibrating rod level switch has significantly improved mechanical strength and anti-hanging ability through a double-tube design, reducing maintenance requirements and improving detection accuracy and reliability.

These advantages have performed well in various industrial applications, making it a leading product in the field of vibrating rod level switches.