As industrial automation and technological advancements surge, Programmable Logic Controllers (PLCs) have become essential in modern industrial processes. Often described as an advanced relay control panel, PLCs significantly reduce industrial control costs while enabling centralized management and automation. For anyone aspiring to master PLCs, a solid understanding of its basics is indispensable. Let’s delve into 15 foundational PLC concepts with explanations, examples, and practical insights.

1. What Are the Interfaces Beyond the CPU, Memory, and Communication Ports in a PLC?

- Input Interface: Receives signals from controlled devices. Using optoelectronic couplers and input circuits, it determines whether internal circuits are engaged or disengaged.

- Output Interface: Delivers program execution results to external loads. This is achieved through optoelectronic couplers and output devices such as relays, thyristors, or transistors.

2. What Are the Core Components of a PLC, and Their Functions?

- CPU: The brain of the PLC, responsible for processing instructions, managing data, and diagnosing errors.

- Memory: Stores system configurations, user programs, and execution data.

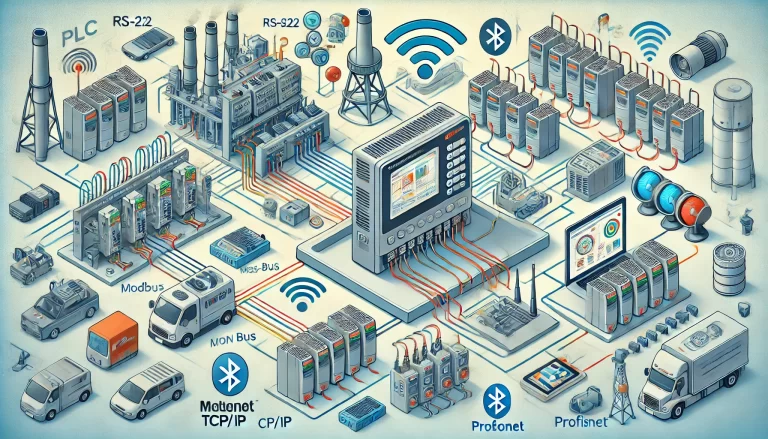

- I/O Interfaces: Facilitate communication between the PLC and industrial equipment, both for receiving inputs and delivering outputs.

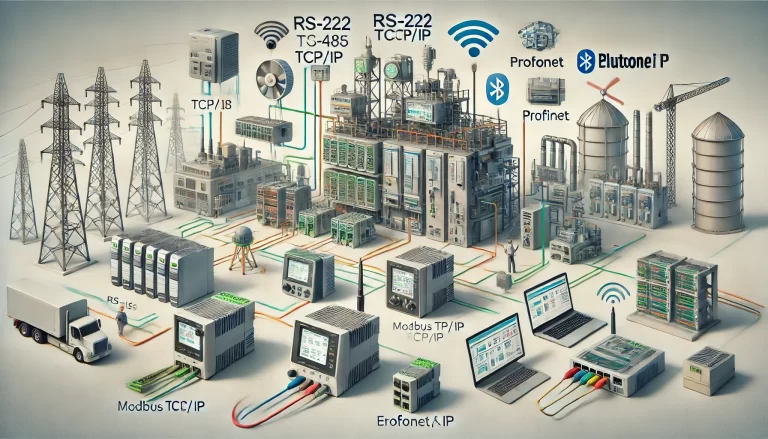

- Communication Ports: Enable data exchange with devices like monitors, printers, and other controllers.

- Power Supply: Ensures stable operation of the PLC.

3. Types of Output Interfaces in PLCs and Their Characteristics

- Thyristor Output: Suitable for AC loads, known for fast response and high switching frequencies.

- Transistor Output: Typically used for DC loads with similar advantages in speed and frequency.

- Relay Output: Compatible with both AC and DC loads but slower in response and limited in switching frequency.

4. Structural Types of PLCs

- Integrated Type: Combines CPU, power supply, and I/O modules in a single chassis. Compact and affordable, this type is ideal for small-scale systems.

- Modular Type: Each component is a separate module, providing flexibility for expansion and easier maintenance. Commonly used in medium to large systems.

- Stacked Type: A hybrid design where components are individual modules connected via cables, offering flexibility and compactness.

5. What Is the PLC Scanning Cycle?

The scanning cycle encompasses five stages:

- Internal Processing: Handles internal diagnostics and maintenance tasks.

- Communication Service: Exchanges data with external devices.

- Input Sampling: Reads input signals at the start of the cycle.

- Program Execution: Processes the user program.

- Output Refresh: Updates output devices with the program’s results.

The duration of the scanning cycle depends on the CPU’s processing speed, hardware configuration, and the length of the user program.

6. How Does a PLC Execute User Programs?

PLCs operate on a cyclic scanning mechanism, progressing through:

- Input Sampling: Reads the current status of inputs.

- Program Execution: Executes user-defined instructions.

- Output Refresh: Updates output statuses based on the program.

7. Advantages of PLCs Over Relay Control Systems

- Flexibility: Control methods can be easily modified by reprogramming, and PLCs have virtually unlimited contact points.

- Reliability: Robust design and built-in self-diagnostic features ensure high reliability.

- Speed: Operations occur at microsecond levels, far surpassing relay systems.

- Advanced Functions: Integrated counters and timers offer high precision and versatility.

- Ease of Maintenance: Self-check and monitoring capabilities simplify troubleshooting and maintenance.

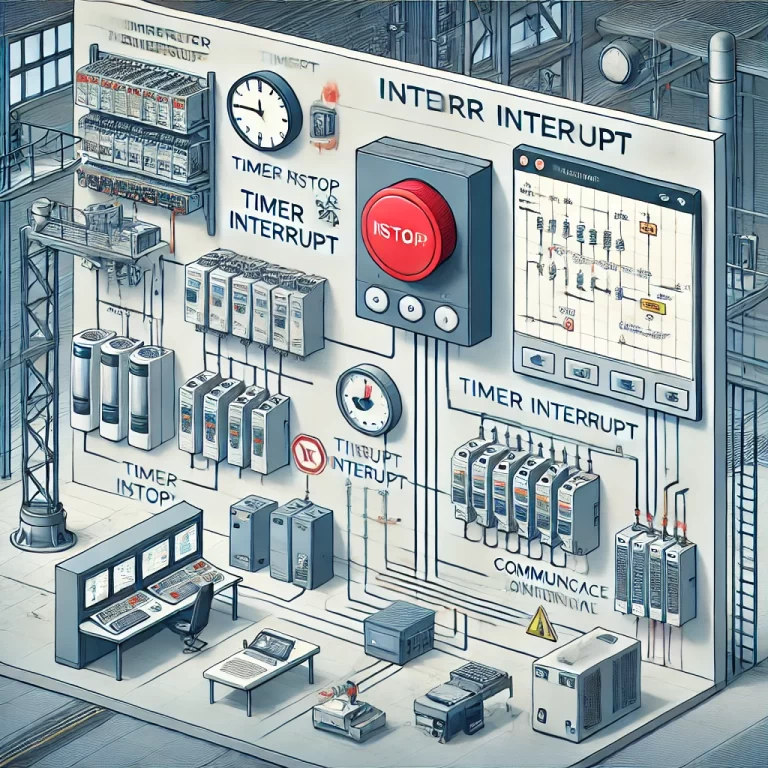

8. Why Do PLCs Exhibit Output Response Delays?

Output delays arise due to the PLC’s cyclic scanning nature:

- Input signals are read only during the input sampling stage.

- Program results are updated during the output refresh stage.

Solutions:

- Use direct input/output sampling.

- Employ interrupt-based I/O operations or intelligent I/O modules.

9. What Are the Internal Relays in the FX0N Series PLC?

- Input Relays

- Output Relays

- Auxiliary Relays

- Status Registers

- Timers and Counters

- Data Registers

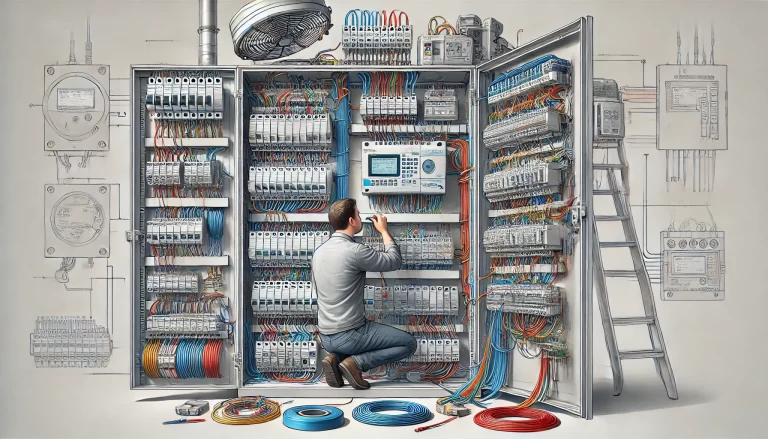

10. How to Choose the Right PLC?

- Model Selection: Consider structural type, installation methods, functionality, and reliability.

- Capacity: Evaluate I/O points and memory capacity.

- Modules: Choose appropriate I/O modules for digital and analog inputs/outputs.

- Additional Equipment: Select suitable power modules, programming devices, and other peripherals.

11. Characteristics of Centralized Sampling and Output in PLCs

- Centralized Sampling: Input states are read only during the input sampling phase of a scan cycle, ignoring any changes thereafter.

- Centralized Output: Outputs are updated only during the output refresh phase, enhancing noise immunity but introducing delays.

12. What Are the Working Principles of PLCs?

PLCs operate using centralized sampling, centralized output, and cyclic scanning:

- Inputs are read once per cycle.

- Outputs are refreshed once per cycle.

- Instructions are executed sequentially within the cycle.

13. Key Components of an Electromagnetic Contactor

- Electromagnetic System: Generates magnetic force to move the armature.

- Contacts: Facilitate circuit switching.

- Arc Suppression: Prevents damage from arcing.

- Spring Mechanism: Ensures contact reset when de-energized.

14. What Is a PLC?

A PLC is an industrial digital computer designed to control machines or processes through programmable logic. It handles operations such as:

- Logic and sequence control

- Timing and counting

- Mathematical computations

PLCs are engineered for seamless integration into industrial systems, offering scalability and functionality.

15. How Do PLCs Differ from Relay-Based Systems?

- Components: PLCs utilize microprocessors and memory, while relays are mechanical.

- Contact Points: PLCs have unlimited “virtual” contacts compared to physical ones in relays.

- Programming: PLCs are programmed with instructions, offering flexibility compared to fixed wiring.

- Operation: PLCs work in cycles, whereas relays operate instantly on input changes.

Practical Application of PLCs

To make these concepts more tangible, let’s consider an example: A factory conveyor system controlled by a PLC can dynamically adjust speeds, count products, and synchronize robotic arms — a task nearly impossible with traditional relay systems.

Interactive Challenge

Now it’s your turn! Can you answer these questions and test your knowledge? Understanding these principles is the first step to becoming a PLC expert. With practice and application, you’ll unlock the full potential of PLCs in industrial automation.