Despite the promise of automation, manual interventions and recurring oscillations still haunt many industrial processes. Are these signs of control limitations — or misconceptions about what “automatic” truly means?

👻 The Two Ghosts of Automation: Manual Intervention & Oscillations

In the battlefield of industrial control, two persistent “ghosts” continue to challenge engineers and operators alike:

Frequent manual interventions

Persistent or periodic oscillations in process variables

These are not just operational annoyances — they are clear symptoms of deeper system deficiencies. A truly successful automatic control system must eliminate both, allowing the operator to shift from “emergency firefighter” back to a process supervisor, and ensuring variables follow their setpoints with stability and autonomy.

🧤 Ghost #1: Manual Interventions — A Sign of Control System “Trust Collapse”

When operators are constantly adjusting valves, bypassing controllers, or frequently modifying setpoints, it reflects a fundamental failure of trust in the automation system.

🔹 Symptoms of Inadequate Automation:

Poor disturbance rejection

Slow setpoint tracking

Control instability and risk accumulation

In such cases, experienced operators are forced to rely on intuition and manual corrections to compensate for the shortcomings of the control loop.

🔹 Hidden Costs of Manual Interventions:

Human resource strain: Continuous monitoring and intervention drain attention and increase workload, especially in multi-unit plants.

Suboptimal performance: Manual actions rarely match the precision of a well-tuned control system, leading to quality variation, higher energy consumption, and reduced output.

Inconsistency: Different operators, or even the same operator at different times, may act differently — resulting in variability between batches and shifts.

Knowledge loss risk: Relying heavily on experienced operators can hide underlying process or control issues. Once those operators leave, chaos may ensue.

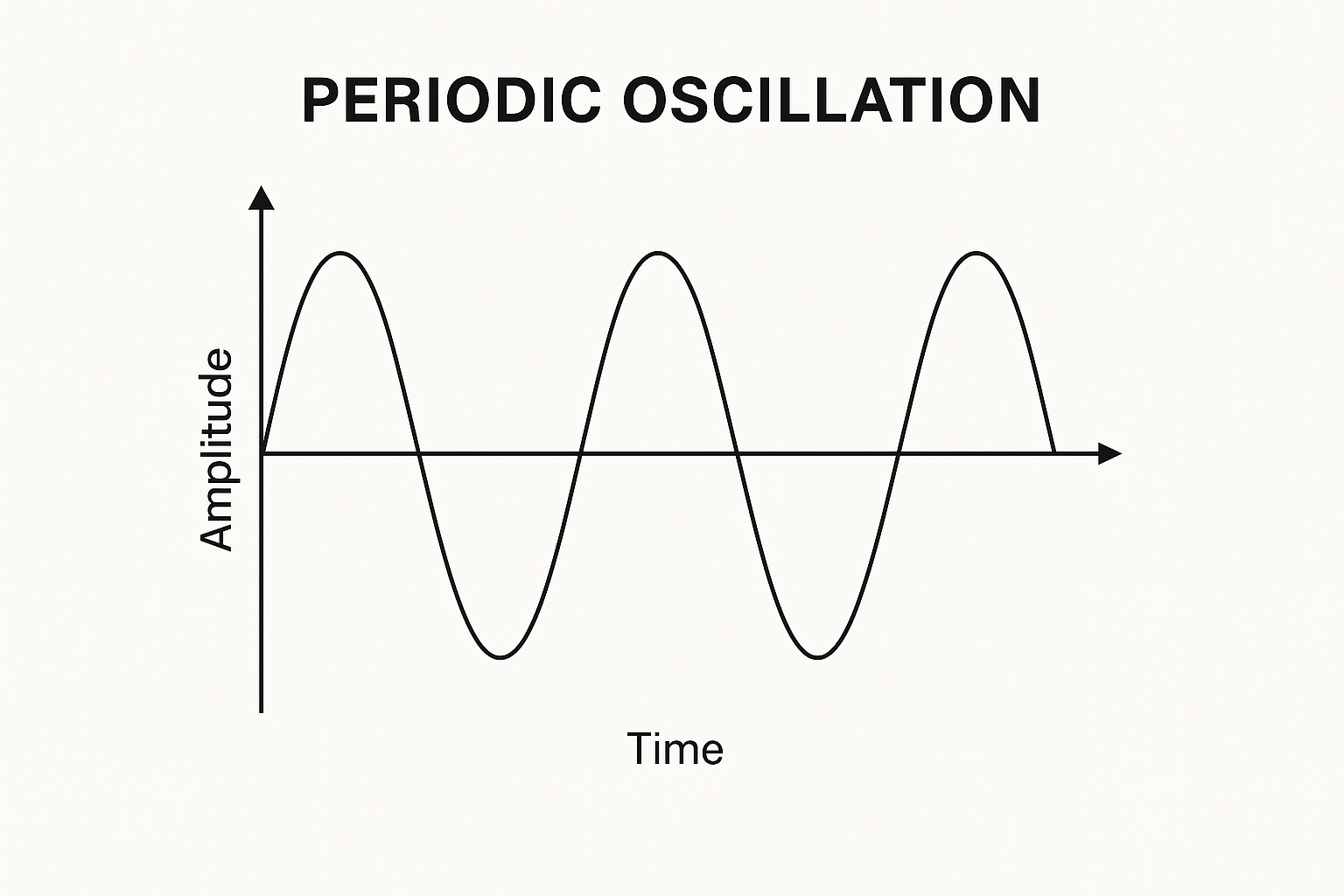

📉 Ghost #2: Cyclical Oscillations — The Poison of Stability

Periodic or sustained oscillations are not just noise — they are a disease in control loops, and the consequences are far-reaching.

🔹 Process Destruction:

Accelerated equipment wear: Actuators, pumps, and valves suffer from constant back-and-forth movement.

Product inconsistency: Fluctuations in temperature, pressure, level, or composition lead directly to off-spec products.

Energy inefficiency: Oscillating variables often translate into unnecessary usage of steam, electricity, or cooling water.

🔹 Systemic Disruption:

Oscillations in one loop (e.g., flow) often ripple downstream, disturbing level, pressure, and temperature loops. This domino effect can compromise entire unit or plant stability.

🔹 Root Cause Concealment:

Oscillations frequently mask deeper problems: sticky control valves, faulty transmitters, poor loop tuning, or even resonance in process piping.

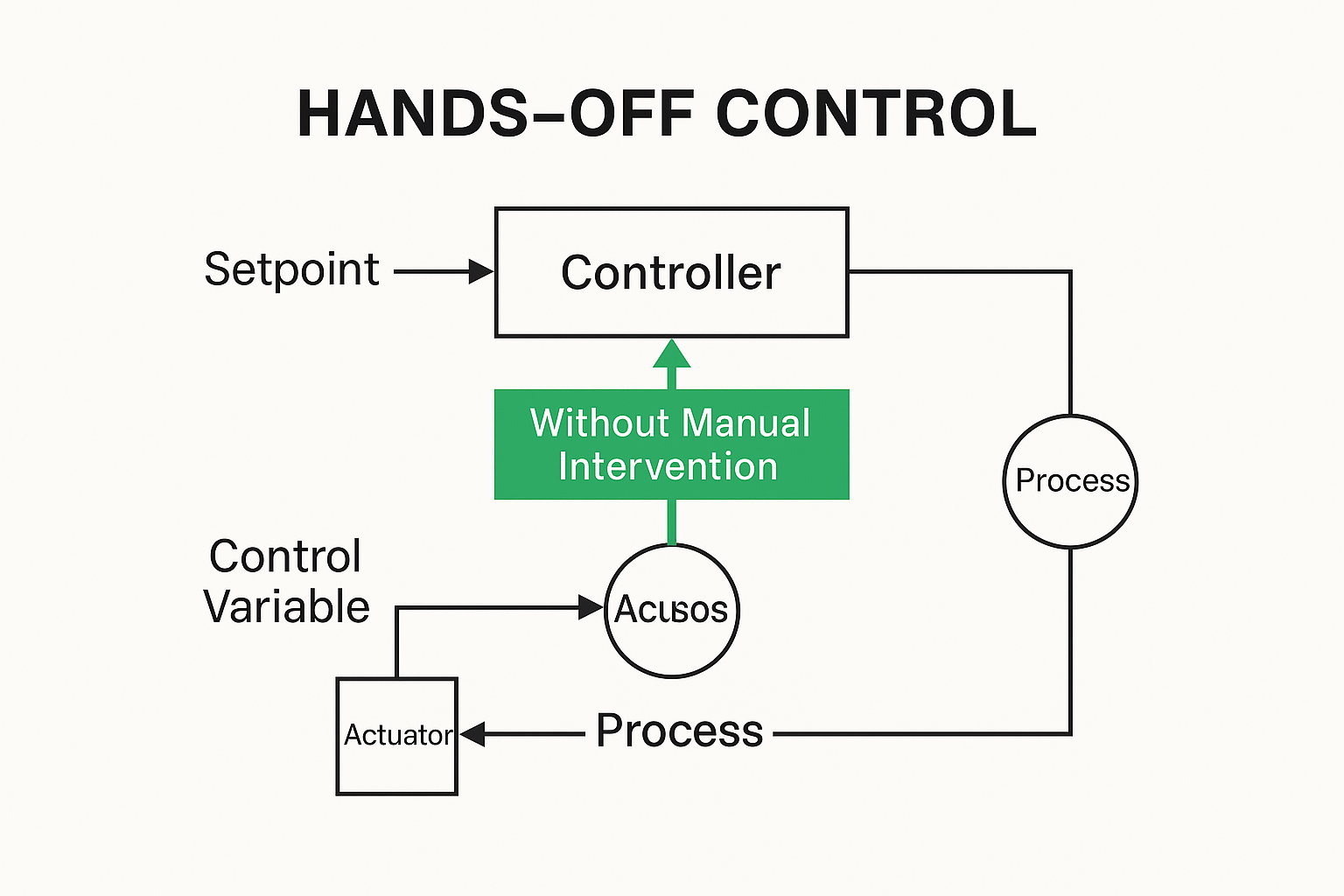

🧭 A Unified Goal: Autonomous and Robust “Hands-Off” Control

Eliminating manual interventions and oscillations is not a two-step process — it is a unified journey toward high-performance automation.

Stability enables autonomy: No operator will “let go” if the system is unstable.

Autonomy proves stability: A system that maintains smooth operation under normal conditions and disturbances — without intervention — is, by nature, robust and well-tuned.

🎯 The Value of Hands-Off Control:

Enhanced safety: Reduces risks from human errors and control-induced equipment failures.

Consistent product quality: Stable process variables are key to repeatable output.

Optimized productivity: Maximizes throughput, reduces waste, lowers energy/material usage.

Lower O&M costs: Less wear and fewer interventions translate to savings.

🚀 The Twin-Zero Pursuit: Zero Manual Intervention + Zero Sustained Oscillation

The ultimate mission of automation is clear:

📌 “Zero unnecessary manual intervention”

📌 “Zero sustained process oscillation”

These are not utopian goals — they are technical challenges that must and can be overcome.

🔧 Practical Engineering Recommendations:

1. Tune for Stability First

Understand the process dynamics (e.g., fast flow, integrating level, delayed temperature).

Avoid derivative action, use integral carefully, and set proportional gain conservatively.

2. Embrace Advanced Strategies

Implement feedforward, cascade, or adaptive control schemes to improve robustness and responsiveness.

3. Monitor, Diagnose, Act

Continuously evaluate loop performance.

Trace and eliminate root causes of oscillations and intervention triggers.

4. Hardware and Process Health Check

Ensure valves and transmitters are in good condition.

Validate that process design supports control objectives.

🧠 From “Looks Automatic” to “Truly Autonomous”

When an automation system successfully suppresses both manual interventions and cyclical oscillations, it completes the transformation from “automatic in appearance” to “autonomous in essence”.

This is the ultimate proof of control system engineering — a foundation for safe, efficient, and high-quality industrial production.