1. Introduction

As industrial processes evolve, hazardous substances such as flammable gases, vapors, dusts, and fibers are commonly present in production, processing, storage, and transportation.

Explosion accidents, if not prevented, can lead to equipment damage, production downtime, and even severe casualties.

To mitigate such risks, the concept of hazardous area zoning and classification has become a fundamental element of industrial safety management, enabling targeted protective measures and equipment selection.

2. Historical Development

2.1 Early Origins

In the early 19th century, frequent gas explosions in coal mines led to inventions like the Davy Lamp. However, there was no systematic zoning—only simple classifications such as “gassy” vs. “non-gassy.”

2.2 Industrial Revolution and Growing Needs

The rise of petrochemical and electrical equipment created complex hazardous environments that traditional experience-based methods could not manage effectively. Major accidents in Europe and North America spurred the need for standardized zoning systems.

2.3 Formation of Global Standards

European System (led by UK & Germany): Developed the Zone classification based on frequency and duration of explosive atmospheres.

American System (led by NFPA): Established the Class/Division system based on material type and exposure conditions.

International Harmonization: The IEC 60079 series unified global standards.

Key Milestones:

1975: Introduction of ATEX certification in Europe.

1996: IEC released the revised hazardous area classification standard, promoting global alignment.

3. Core Principles of Zoning

Hazardous area classification is based on:

The frequency, duration, and distribution of explosive atmospheres.

The likelihood of release, ventilation conditions, and process stability.

Key Evaluation Factors:

Release source characteristics

Ventilation effectiveness

Process conditions (normal/abnormal)

Environmental type (indoor/outdoor, confined/open)

4. Zoning System Based on IEC Standards

4.1 Gases and Vapors

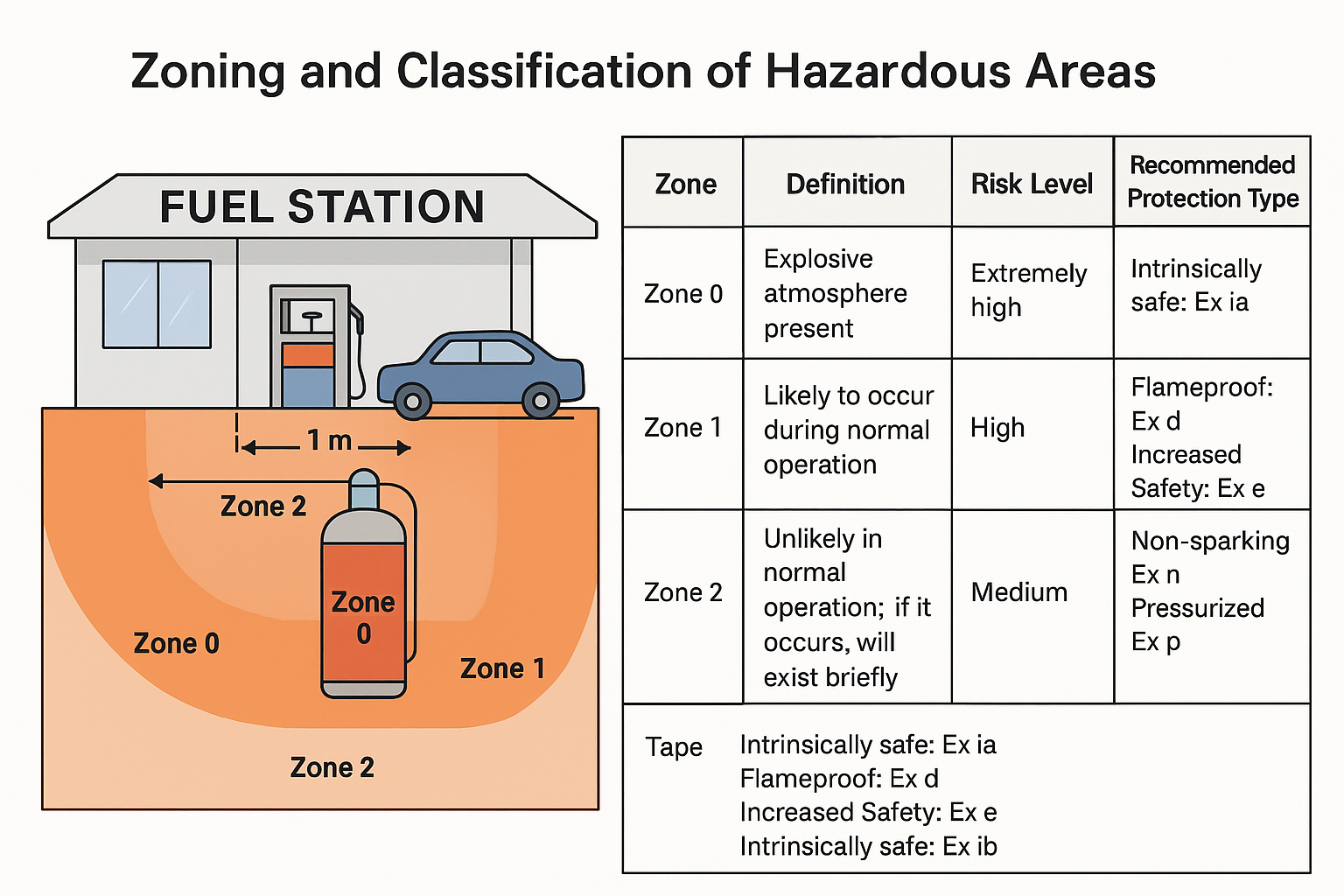

| Zone | Definition | Risk Level |

|---|---|---|

| Zone 0 | Explosive gas atmosphere is present continuously or for long periods. | Extremely high |

| Zone 1 | Likely to occur during normal operation. | High |

| Zone 2 | Unlikely in normal operation; if it occurs, it will exist briefly. | Medium |

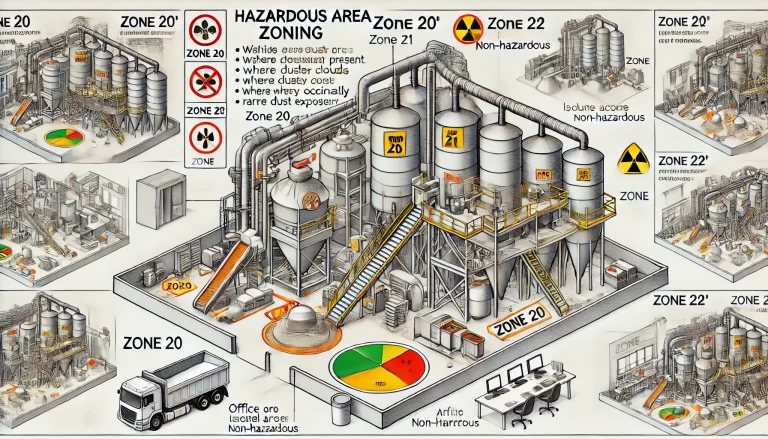

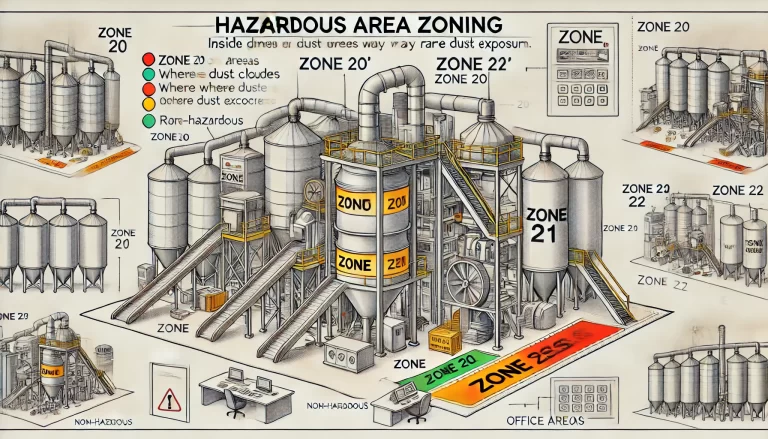

4.2 Combustible Dusts

| Zone | Definition | Risk Level |

|---|---|---|

| Zone 20 | Dust clouds are present continuously or frequently. | Extremely high |

| Zone 21 | Likely to occur occasionally during normal operation. | High |

| Zone 22 | Unlikely during normal operation; if present, short-term only. | Medium |

5. U.S. Class/Division System (NEC/NFPA)

5.1 Classification by Material Type:

Class I: Flammable gases or vapors

Class II: Combustible dusts

Class III: Ignitable fibers or flyings

5.2 Classification by Exposure Frequency:

Division 1: Hazardous atmosphere exists during normal operation

Division 2: Hazardous atmosphere exists only under abnormal conditions

Examples:

Class I, Division 1: Zone with frequent gas exposure

Class II, Division 2: Zone with dust hazard only during malfunction or leakage

6. Key Zoning Determinants

| Factor | Description |

|---|---|

| Substance characteristics | Flash point, explosive limits, minimum ignition energy |

| Release source strength | Continuous, secondary, or emergency releases |

| Duration | Annual exposure time (e.g. >1000 hrs/year = Zone 0) |

| Ventilation level | Good, moderate, or poor |

| Spatial layout | Indoor/outdoor, sealed/open/semi-open environments |

Example:

Continuous flammable gas release >1000 hours/year → Zone 0

Rare leakage during maintenance <1 hour/year → Zone 2

7. Application Case Studies

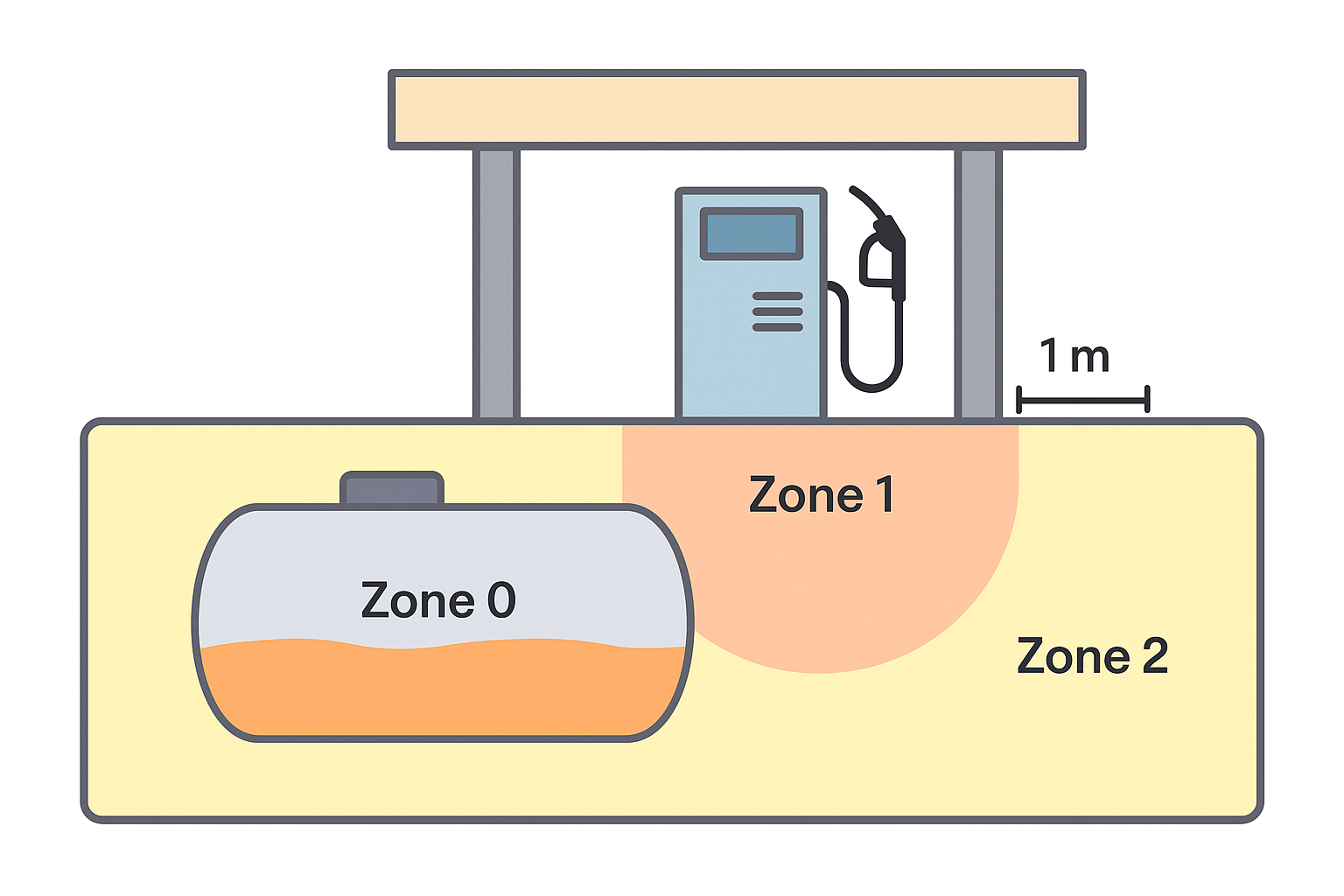

Case 1: Fuel Station

Inside fuel tank: Zone 0

1 meter around nozzle: Zone 1

Further areas: Zone 2

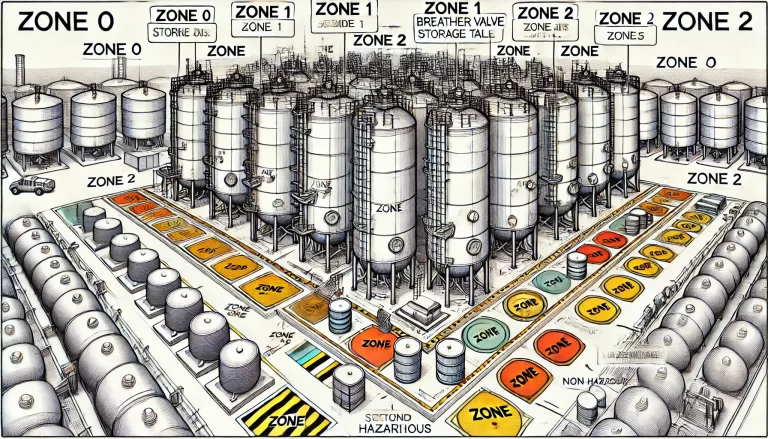

Case 2: Chemical Storage Tank Area

Breather valve: Zone 1

Ground-level vapor area: Zone 2

Distant locations: Non-hazardous

Case 3: Flour Mill

Grinder room: Zone 20

Adjacent machine surfaces: Zone 21/22

Office: Non-hazardous

8. Explosion-Proof Equipment Selection

| Zone | Recommended Protection Type |

|---|---|

| Zone 0 | Intrinsically safe – Ex ia |

| Zone 1 | Flameproof (Ex d), Increased Safety (Ex e), Intrinsically safe – Ex ib |

| Zone 2 | Non-sparking (Ex n), Pressurized (Ex p), simplified protection |

Note: Equipment selection must also consider gas group (e.g., IIA/IIB/IIC) and temperature class (e.g., T1–T6).

9. Emerging Trends

Real-time monitoring: Intelligent sensors continuously track hazardous conditions for dynamic zoning updates.

Risk-based zoning: Moving from static zones to probability-based assessment models.

Global standard convergence: Wider adoption of IEC/ISO standards across regions.

Green explosion-proof technologies: Spark-free design, gas-tight enclosures, suppression-based explosion mitigation.

10. Conclusion

The zoning and classification of hazardous areas originated from hard-learned lessons during the Industrial Revolution. Over time, it has evolved into a globally recognized framework for preventing explosions and ensuring industrial safety.

For modern enterprises, accurate zoning not only fulfills compliance requirements but also safeguards personnel and assets through scientifically guided equipment selection and risk control.