1. General Provisions

1.1 Purpose

This procedure is established to ensure the personal safety of workshop personnel during equipment maintenance, inspection, and commissioning activities. It aims to standardize operational processes, promptly correct unsafe actions, and prevent safety incidents.

1.2 Scope of Application

This procedure applies to all personnel in the instrument workshop, including maintenance staff, operators, shift personnel, work leaders, and supervisors. It covers various activities such as shutdown maintenance, partial power-off work, live-line work, and high-altitude operations.

1.3 Core Principle

The principle of “the supervisor is responsible for the supervision” shall be followed. Supervisors must have solid field experience, be familiar with equipment conditions, safety risks, and emergency measures, and ensure continuous and effective supervision throughout the work process.

2. Supervisor Qualifications and Responsibilities

2.1 Qualification Requirements

Minimum of three years’ relevant work experience in the instrument workshop, with knowledge of equipment structure, performance, and safe operating procedures.

Competence in electrical safety, high-altitude safety, fire and explosion prevention, and hazard identification.

Holder of a valid workshop-approved safety supervision training certificate.

Ability to handle emergencies, including immediate rescue actions.

2.2 Core Responsibilities

Before work: Assist the work leader in completing permits, confirm safety measures (isolation, lockout, grounding, etc.), and brief workers on hazards and precautions.

During work: Remain on-site throughout, monitor operations, ensure safe distance from live/operating equipment (complying with GB 4728 standard), and prohibit violations such as live-line plugging/unplugging of instrument modules.

After work: Oversee site clearance, confirm equipment recovery status, assist in work closure, and record any abnormal situations.

3. Work Supervision Procedure

3.1 Preparation Phase

The work leader designates qualified supervisors according to task type.

Joint safety inspection with work leader and operators (power isolation, grounding, safety ladders, PPE, etc.).

Deliver a pre-job briefing covering tasks, hazards, and emergency measures.

3.2 Monitoring Phase

No personnel may remain alone in hazardous areas (e.g., near HV switchgear, high-temperature equipment, or toxic instrument zones).

For energized or partially de-energized tasks, supervisors must ensure safe clearance (≥0.7 m for ≤10 kV equipment), and verify proper tool use.

Supervisors may not perform other work unless all safety conditions are fully met.

For complex or multi-area tasks, additional supervisors must be appointed and dedicated solely to monitoring.

3.3 Handling Special Situations

If the work leader leaves, a substitute must be formally assigned, with written handover if absence exceeds 4 hours.

Supervisors must stop unsafe acts (e.g., crossing barriers, missing PPE). In urgent cases, suspend work, evacuate personnel, and report immediately.

3.4 Completion Phase

Verify work quality and equipment restoration (instruments reset, valves closed, power restored).

Record details in the Work Supervision Log, including participants, key risks, anomalies, and corrective actions.

4. Special Supervision Requirements

4.1 High-Altitude Work (≥2 m)

Confirm use of certified safety belts (anchored high, used low), helmets, and stable climbing tools.

Prohibit non-essential personnel from entering danger zones below.

Supervisors must not perform climbing work; monitor workers’ physical condition throughout.

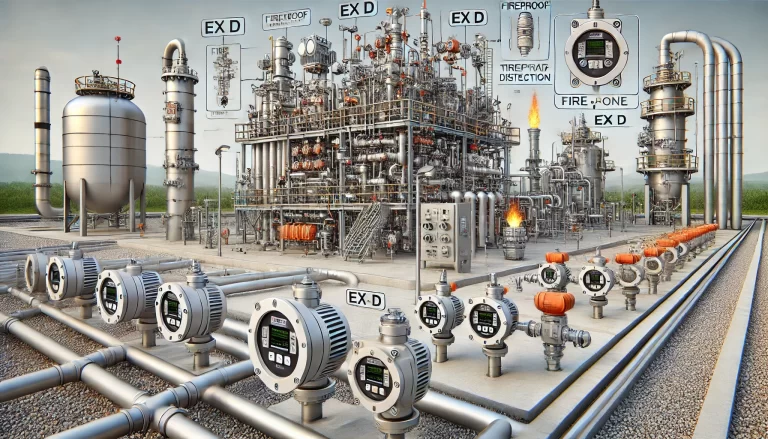

4.2 Live-Line Work (Instrument Loop Energized)

Supervisors must hold live-line supervision certification.

Ensure operators use insulated gloves, shoes, and tools.

Monitor terminal contacts, circuit load, and prepare an emergency cutoff switch.

4.3 Maintenance Duty Supervision

Duty maintenance staff may require operators to act as temporary supervisors, with equivalent responsibility.

Operators acting as supervisors are equally accountable for safety outcomes.

5. Rewards and Accountability

5.1 Rewards

“Safety Supervisor of the Month” recognition, with monetary rewards.

Annual performance evaluation priority for compliant supervisors.

5.2 Accountability

Minor safety events due to negligence (e.g., minor injury, small equipment failure): 10–20% performance penalty and workshop notice.

Major incidents (e.g., serious injury, equipment damage): penalties per company’s Safety Production Accountability Measures, including training suspension, demotion, or legal responsibility.

If workers refuse correction and commit unsafe acts, they bear primary responsibility; supervisors failing to stop them share secondary responsibility.

6. Supplementary Provisions

Matters not covered herein shall follow the company’s Safety Management Regulations and Workshop Safety Codes.

The instrument workshop is responsible for interpretation and shall revise this procedure annually.

This procedure takes effect from the date of issuance, replacing the previous interim rules.

Prepared by: Instrument Workshop Safety Team

Reviewed by: Workshop Director

Approved by: Company Safety Officer