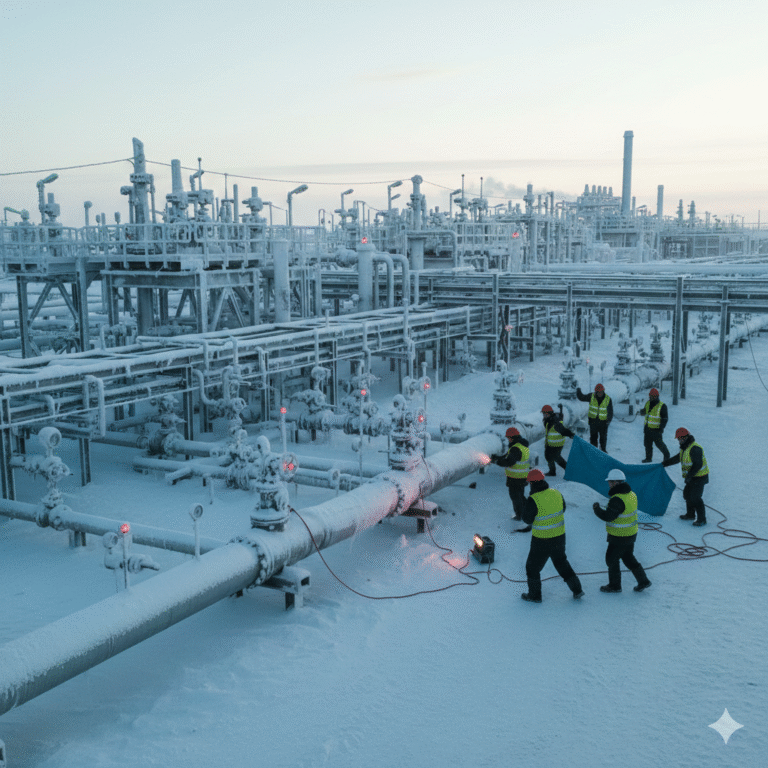

Chemical plants often consist of numerous interconnected equipment, pipelines, and instruments working together to ensure smooth operation. Given the scale of modern petrochemical plants, continuous production demands, and the use of flammable and hazardous materials, preventing freezing and condensation in cold climates becomes crucial. Due to the significant height differences between equipment, fully enclosed solutions are often not feasible. Hence, managing winter freeze and condensation issues requires effective methods tailored to each facility’s specific needs.

Here are the four commonly used methods for preventing freezing and condensation in chemical plants during the winter:

1. How to Empty Equipment?

Intermittently Used or Long-Term Idle Equipment and Pipelines:

For these systems, the following steps should be followed for emptying:

Close relevant valves, and if necessary, add blinds to prevent leakage.

Open the high-point vent valve and low-point drain valve to remove the materials inside the equipment.

Use nitrogen for purging and replacing the remaining materials.

Keep the low-point drain valve open for regular inspection.

Underground Valve Pit Facilities:

For facilities without heating, such as fire equipment (e.g., water cannons, fire hydrants), shut off the root valve in the valve pit and empty the water through the drain valve. Leave the drain valve open and ensure the nozzle is facing downward. Some fire equipment with built-in return systems may not require this step.

Temporary Equipment and Pipelines:

After temporary use, empty the media from the equipment, pipelines, or hoses and use nitrogen to purge them. If possible, store them in insulated rooms.

2. How to Insulate?

Insulating Equipment, Pipelines, and Accessories:

Before the winter season begins, a thorough check should be performed, especially for unheated systems that rely solely on the material temperature for freeze prevention. Pay special attention to equipment and pipeline endpoints, blind ends, and on-site pressure gauges to ensure proper insulation.

Indoor Heating and Insulation:

Ensure that doors and windows in workshops are properly sealed. Start heating systems in indoor areas promptly.

Underground Valve Pit Insulation:

Use plastic sheeting to seal off the valve pits and apply insulation measures as necessary.

3. How to Heat?

Hot Water Heating:

This method is suitable when operating temperatures are low, or high-temperature heating media cannot be used.

Hot water (80–90°C) is used as a heat source and is circulated through heating pipes to warm equipment and instruments. However, due to the lower water temperature, hot water heating is mainly used for freeze prevention rather than condensation prevention.

The system needs to be well-insulated to ensure efficient heat transfer, and heating pipes should be laid according to strict standards. Although hot water heating consumes less energy, it requires complex setup and is more commonly seen in large state-owned enterprises.

Steam Heating:

Steam heating is widely used in petrochemical plants.

The heat released from the steam heating pipe compensates for heat losses in the main pipeline and surrounding environment. The use of prefabricated hard insulation shells and adequate spacing between the heating pipe and the main pipeline helps optimize heat transfer.

This method is most suitable for temperatures below 150°C.

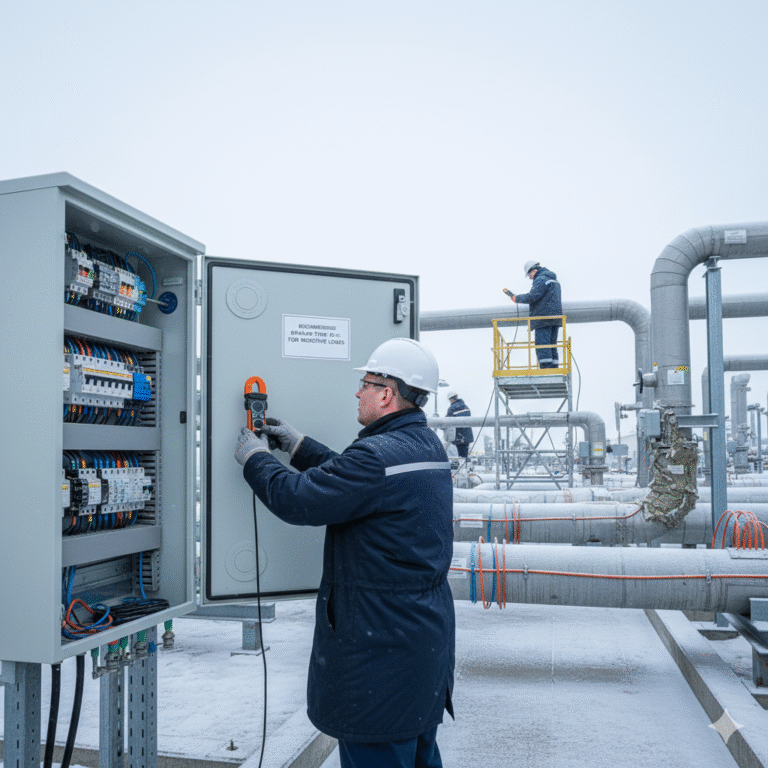

Electric Heating:

Electric heating is an effective and widely applied solution for pipeline insulation and freeze prevention. The heating media release a certain amount of heat, directly or indirectly compensating for heat loss to maintain the required temperature.

Circulating Hot Media:

Used widely in petroleum, chemical, and heat treatment industries, circulating hot media such as heat transfer oils can be used for large-scale heat conversion and transfer with precise temperature control.

Selecting the appropriate heating medium should consider the material properties, operational requirements, construction difficulty, and running costs, ensuring the system’s efficiency and avoiding new issues.

4. How to Implement Circulation?

Circulation methods are mainly used for intermittently running or long-term idle equipment and pipelines, where the methods mentioned earlier (emptying, insulation, and heating) are either insufficient or unfeasible. There are four primary methods:

Circulating Return from Operating Equipment:

This is commonly used for backup equipment to prevent freezing. By connecting a bypass line near the pump outlet or using a single valve with an opening, the material can be circulated back to the standby equipment.

Cross-Connecting Inlet and Outlet Pipelines:

This method is used to prevent freezing in idle heat exchanger inlet and outlet pipelines by connecting small-diameter lines between the inlet and outlet valves to maintain circulation.

Small-Scale Circulation:

In this method, the outlet valve of backup equipment is kept small to reduce the circulation volume, ensuring sufficient freeze protection.

Continuous or Intermittent Media Drainage:

This method applies to pipelines without the possibility of establishing circulation at their ends, such as hose stations, storage tank dewatering pipelines, valve drains, and steam lines’ low-point drainage valves. A minimal flow is maintained to prevent freezing.

Key Points for Freeze Prevention Checks:

Regular freeze prevention inspections are crucial to identifying and resolving issues promptly. Inspections help evaluate the effectiveness of freeze prevention methods and ensure systems are functioning as expected. Key check points include:

Steam Heating Pipes: Regularly check steam traps to ensure proper drainage. Use temperature guns or touch tests on valves to confirm their functioning.

Hot Water Heating: Use flow indicators or temperature checks to monitor the hot water heating system.

Electric Heating: For electric heating systems with temperature indicators, regularly check the readings and use temperature guns for accurate measurements.

Sealed Workshop Areas: Regularly check the seal of doors, windows, and heating systems to ensure optimal indoor temperature.

Valve Pit and Equipment Inspections: Regularly inspect empty equipment and pipelines for material leakage or freeze blockages. Conduct checks with hammers to identify blockages and take corrective actions when necessary.

Conclusion:

Preventing freezing and condensation in chemical plants requires careful planning, proper application of different methods, and regular maintenance. By following these measures, facilities can effectively reduce the risk of freezing and maintain smooth operations during the cold winter months.