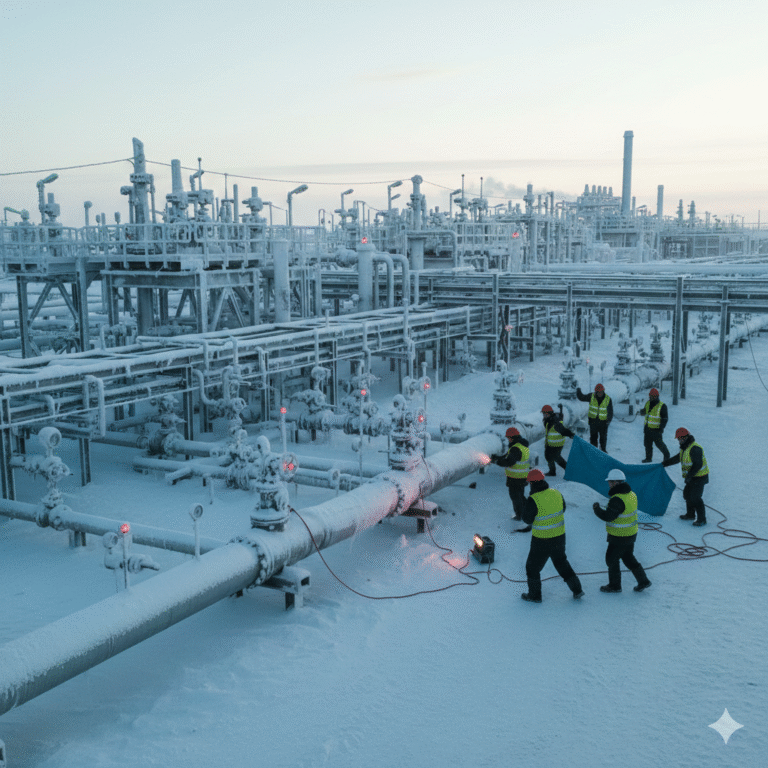

In the winter months, many factories, especially in northern regions, are most concerned not with large equipment, but with the intricate network of pipelines and instrumentation spread throughout the facility. Gas supply pipes may freeze, differential pressure cells may become inaccurate due to ice accumulation, and level measurement lines may become blocked with ice. Even the simplest pressure taps can become blocked due to sudden drops in temperature.

In years of frequent cold waves, many factories have experienced situations where temperatures drop by just 10 degrees, leading to simultaneous alarms from dozens of instrument points. Engineers scramble to fix the issues using electric blankets, space heaters, and temporary heaters, but these solutions are neither sustainable nor safe, and they cannot guarantee long-term reliability.

In fact, instrumentation is only one of the most sensitive components in the winter insulation process. The real need for insulation extends to various process pipelines, valves, flanges, and storage tanks. To ensure that these systems remain stable in freezing temperatures, factories need a reliable, self-regulating heat source. The unsung hero here is the heat tracing system, which keeps the flow of fluids in pipelines even in severe cold.

Many people think heat tracing is complicated, but its core purpose is quite simple: to “add heat” to pipes, valves, tanks, and other critical components, preventing the medium inside from cooling down, becoming too viscous, or freezing.

However, when it comes to implementation in the field, there are numerous technical details involved. In this article, we’ll explain the heat tracing system from the basics, so that even engineers new to the field can understand its importance and application.

What is a Heat Tracing System?

In factories operating in cold climates, the main concern is often not the breakdown of equipment, but the freezing of common pipelines. When liquids freeze or become too viscous, their flow is interrupted, valves may rupture, pumps may overload, and instruments may fail, resulting in the entire production system coming to a halt. To avoid such risks, industrial facilities generally require a system that can maintain the temperature of critical components even in freezing conditions. This is where the heat tracing system comes in.

A heat tracing system essentially provides stable heat compensation to pipes, valves, storage tanks, and instrumentation, ensuring that the medium within remains fluid and does not freeze, solidify, or crystallize. You can think of it as a “thermal jacket” for industrial equipment, keeping it operating safely and efficiently during winter.

Why is the Heat Tracing System Important?

Many common materials undergo detrimental changes when exposed to low temperatures. Water freezes quickly and can cause pipes to rupture; diesel and crude oil become viscous and difficult to pump at low temperatures; some chemical mediums crystallize within specific temperature ranges; and other materials fail to meet processing requirements due to cooling. A failure at any step can trigger a chain reaction, leading to production stoppages or even safety incidents.

The heat tracing system ensures that in cold conditions, the temperature of pipes and the medium inside remains at a safe level. It ensures that materials “remain mobile, flow smoothly, and avoid blockages.”

In chemical plants, power plants, food factories, and various transportation systems in northern regions, heat tracing is often an indispensable infrastructure element.

How Does a Heat Tracing System Work?

Heat tracing systems can be divided into three main types: electric heat tracing, steam tracing, and hot water or thermal oil tracing. Of these, electric heat tracing is the most commonly used because it doesn’t depend on a large steam network, offers flexible installation, precise temperature control, and is more suitable for modern, automated factories.

The core principle of an electric heat tracing system is to directly heat along the length of the pipeline or container to prevent freezing or maintain a specific temperature.

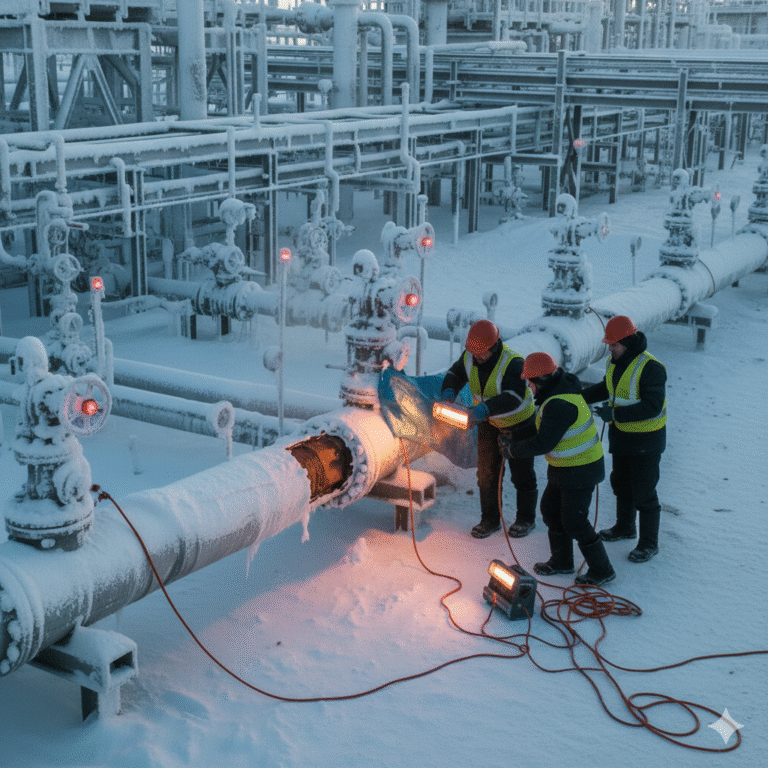

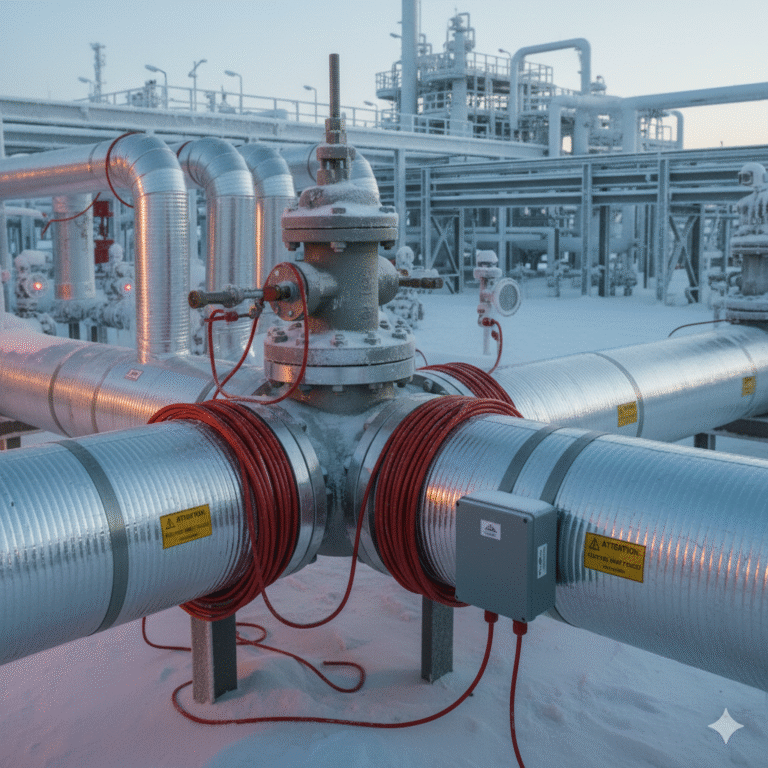

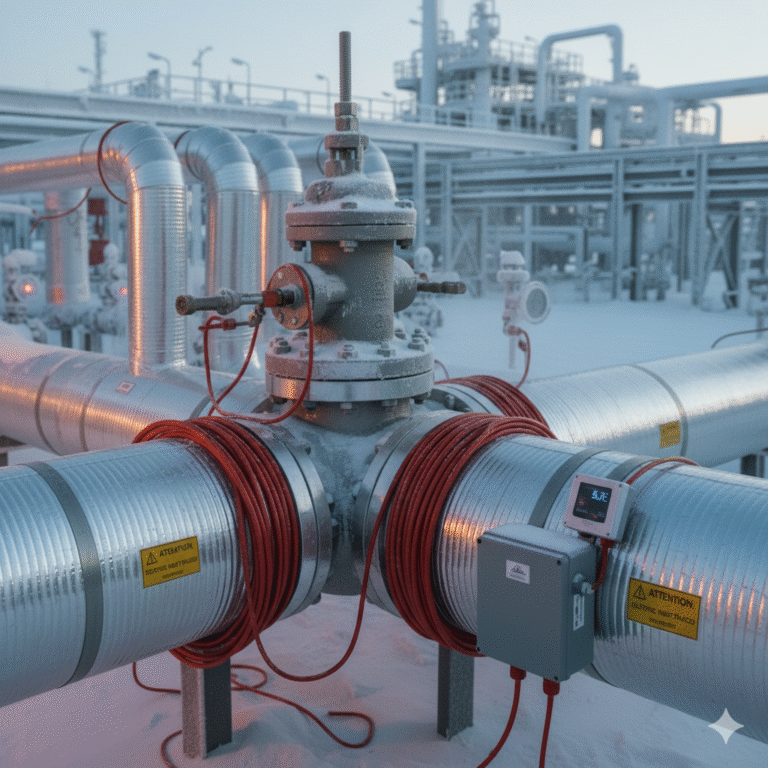

First, a high-temperature heat tracing cable is tightly attached to the pipeline. Then, it is powered through a special interface (usually a simple power connection box). For systems that require precise temperature control, a digital thermostat can be used, which not only powers the cable but also continuously monitors and adjusts the pipeline temperature.

When there are branches or junctions that require heating, multi-entry connection boxes can distribute the heat tracing cable and extend the heating range to those areas. End seals are installed at the ends of the heating cables to prevent moisture ingress and physical damage.

After installation, the entire system is wrapped in insulation material to minimize heat loss to the surrounding environment, thus improving the energy efficiency of the entire system. Finally, heat tracing warning labels are affixed to the outer surface of the insulation to alert maintenance and emergency personnel of the active heat elements underneath.

Three Common Types of Electric Heat Tracing

In electric heat tracing systems, the type of heating tape used determines the system’s performance, application, and safety. The three most commonly used types are: self-regulating heat trace cable, constant wattage heat trace cable, and mineral insulated cables.

Self-regulating Heat Trace Cable

This is the most commonly used type. Its structure contains materials that change their resistance with temperature. As the temperature drops, the cable automatically increases its power output; as the temperature rises, it decreases the power to avoid overheating. It’s essentially a heat trace cable with its own “brain”—if it gets too hot, it regulates itself.

Its key advantages include ease of installation, long lifespan, and high safety. It’s widely used for freezing prevention, low-temperature insulation, instrument lines, and various food and chemical applications.

Constant Wattage Heat Trace Cable

Unlike self-regulating cables, constant wattage heat trace cables do not adjust their power output. Once powered on, they consistently heat at a set wattage. This makes them ideal for long-distance heating applications, providing even and stable heat.

Since they do not adjust their power output, they require temperature controllers for safety. These cables are perfect for medium-temperature insulation, continuous production lines, and long-distance pipeline applications.

Mineral Insulated Cable

This high-performance heat tracing option is built for extreme conditions. With a metal casing and a heating core made of nickel-chromium wire and magnesium oxide insulation powder, it can operate in temperatures ranging from 200°C to 600°C.

Its key benefits include resistance to fire, corrosion, and radiation, making it ideal for high-temperature, chemical, petrochemical, nuclear, and other extreme environments. These cables are highly reliable, with a long service life, but require specialized installation and higher costs.

Components of a Heat Tracing System

A heat tracing system includes more than just the heat tracing cable. It also consists of power connectors, junction boxes, explosion-proof boxes, temperature control devices, mounting materials, and most importantly, the insulation layer. The heat tracing cable provides heat, while the insulation retains that heat. Both are essential for an effective system.

In practice, the installation and insulation quality play a critical role. If insulation is damaged or improperly installed, even the most powerful heat tracing cable won’t achieve the desired results.

Designing a Heat Tracing System

When designing a heat tracing system, engineers must consider several core factors:

Determine the Target Temperature

Different materials require different temperatures. For example:

Water: Maintain at 5-10°C to prevent freezing.

Diesel: Must stay above 20°C to prevent thickening.

Crude oil: Typically needs 60-80°C.

Fats and resins: May need 100°C or more.

This will determine the type of heating cable, its power rating, and the control method.

Consider the Outdoor Minimum Temperature

Calculate how much heat will be lost from the pipeline, known as “heat loss.” Factors include pipe diameter, insulation thickness, insulation material, outdoor temperature, wind speed, and medium temperature.Select the Required Heating Power

Anti-freeze: 10-20 W/m.

Mid-temperature insulation: 20-40 W/m.

Process heating: 40-60 W/m.

High-temperature process heating: 80-200 W/m.

Determine the Layout of the Heating Cable

This includes the type of cable layout—single, spiral, or parallel installation—and additional heating for critical components like valves and flanges.Temperature Control and Electrical Design

For simple systems, mechanical thermostats may suffice, while more precise systems require digital controllers or sensors (e.g., PT100) and control cabinets.

Common Issues in Heat Tracing Systems

In practice, common issues in heat tracing systems are often related to improper installation, inadequate insulation, or faulty temperature controllers. Problems such as insufficient insulation, cable damage during installation, or power supply issues (e.g., long cables causing voltage drop) are frequent. These issues can lead to insufficient heating and equipment failure.

Conclusion

For those new to heat tracing systems, learning about material properties, understanding different types of heat tracing cables, and becoming familiar with heat loss calculations and installation practices will help develop a solid foundation. A well-designed heat tracing system is essential for ensuring factory operations continue smoothly throughout the winter, keeping everything flowing and operational.