Sulfur trioxide (SO₃) is a highly reactive and corrosive chemical compound widely used in industrial applications, particularly in the production of sulfuric acid. Due to its hazardous nature, effective safety measures must be implemented to prevent accidents and ensure workplace safety. However, installing toxic gas detectors specifically for SO₃ is not an appropriate or effective safety strategy. This article explores the reasons why SO₃ should not be monitored using conventional toxic gas detection systems and recommends alternative safety measures.

1. Physical and Chemical Properties of SO₃

SO₃ exhibits unique physical and chemical properties that make conventional toxic gas detectors ineffective:

State of Matter: At room temperature, SO₃ exists primarily as a colorless liquid or solid. It readily reacts with moisture in the air to form sulfuric acid mist rather than remaining in a gaseous state. This transformation makes it difficult for gas-phase detectors to detect SO₃ directly.

Hygroscopic Nature: SO₃ is highly hygroscopic, meaning it aggressively absorbs water vapor from the air. Upon contact with moisture, it instantly forms dense, corrosive sulfuric acid aerosols, rendering gas detection impractical.

2. Incompatibility with Conventional Gas Detectors

Standard toxic gas detectors are designed to detect stable gaseous compounds in the air. However, SO₃ poses several challenges:

Corrosiveness: SO₃ and the sulfuric acid mist it generates are extremely corrosive. This property can damage sensor components, leading to malfunction or inaccurate readings, thereby compromising the reliability of gas detectors.

Rapid Chemical Transformation: The immediate conversion of SO₃ to sulfuric acid mist means that SO₃ does not linger as a gas. Conventional gas detectors cannot effectively monitor this transition, leaving potential leaks undetected.

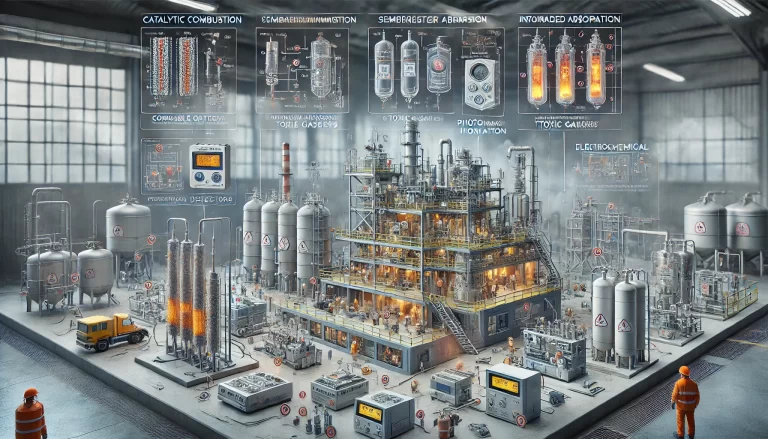

3. Alternative Monitoring and Safety Strategies

Given the limitations of toxic gas detectors for SO₃, alternative safety measures are necessary:

Acid Mist Detectors: Since SO₃ quickly forms sulfuric acid mist upon release, deploying acid mist detectors can provide more effective monitoring of leaks.

Leak Detection Systems: Mechanical and structural integrity checks using infrared thermography or ultrasonic leak detectors can help identify equipment vulnerabilities before a leak occurs.

Ventilation and Containment: Proper ventilation systems and secondary containment measures are crucial to control and mitigate any accidental release of SO₃.

Corrosion-Resistant Materials: Using corrosion-resistant materials for piping, storage tanks, and equipment helps minimize the risk of leaks and structural failures.

Environmental Monitoring: Continuous environmental monitoring for sulfuric acid aerosols can provide early warnings of SO₃ leaks indirectly.

4. Preventive Measures and Best Practices

To minimize the risks associated with SO₃, industries should adopt comprehensive safety practices:

Routine Maintenance: Regular maintenance of storage and processing equipment reduces the chance of leaks.

Employee Training: Workers must be trained in handling SO₃ safely and responding to emergencies.

Emergency Response Plans: Establishing detailed response plans for SO₃ leaks can minimize exposure and environmental impact.

Conclusion

Sulfur trioxide’s unique physical and chemical characteristics make it unsuitable for monitoring with conventional toxic gas detectors. Its rapid transformation into sulfuric acid mist, combined with its high corrosiveness, requires specialized monitoring equipment and comprehensive safety measures. By employing acid mist detectors, enhancing structural integrity, and implementing rigorous safety protocols, industries can effectively manage the risks associated with SO₃ and ensure workplace safety.