1. Background

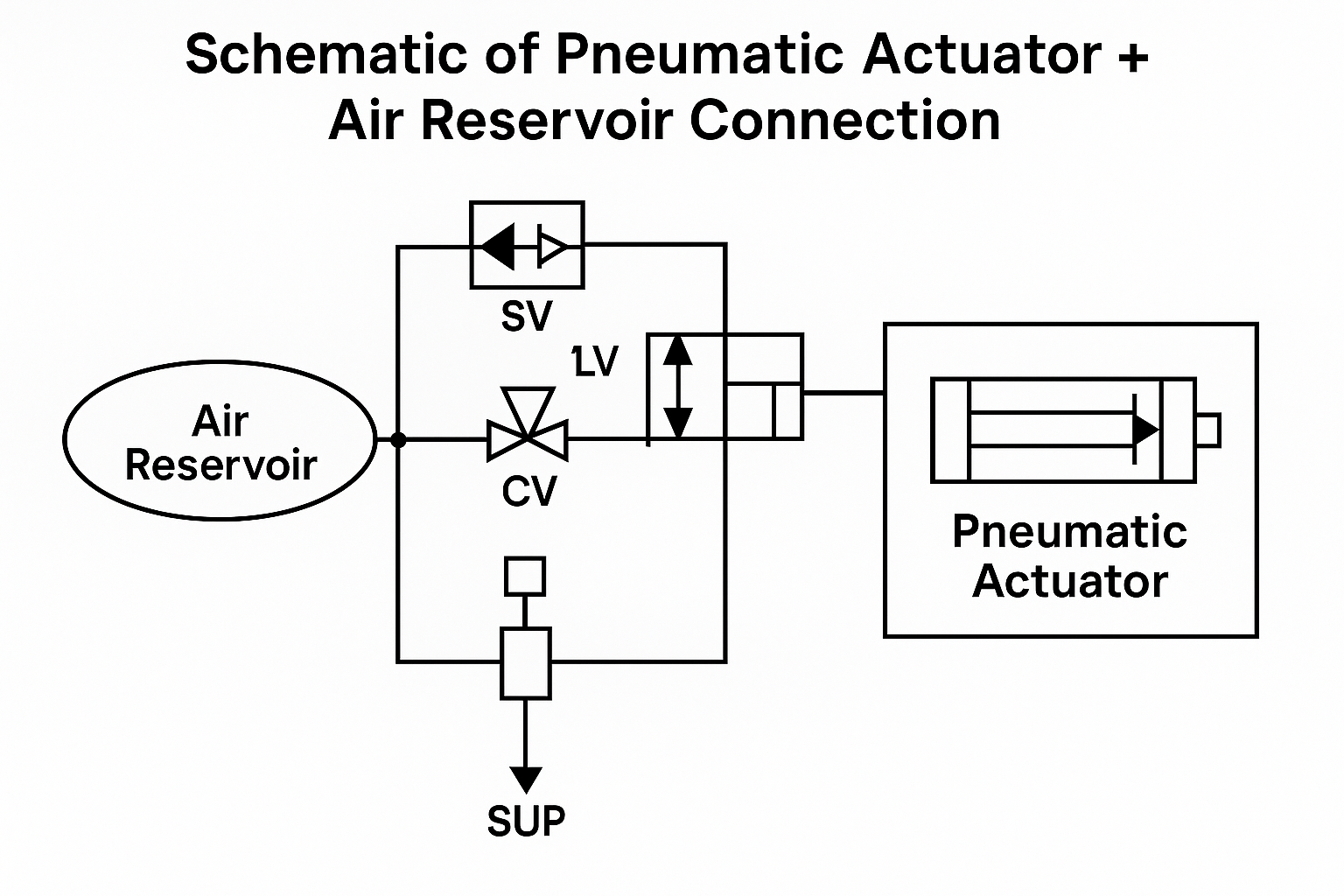

In many field applications, pneumatic valves are installed with an auxiliary air reservoir (air tank), commonly referred to as a “gas bag.” However, feedback shows that operators often connect it incorrectly or even leave it unused, which compromises its intended function.

The air reservoir plays a crucial role: under normal conditions it remains idle, but once the main air supply is interrupted, it provides temporary compressed air to ensure the valve moves to its fail-safe position. Without this safeguard, the valve may lose control during emergencies, leading to safety and process risks.

2. Why Use an Air Reservoir with Pneumatic Valves?

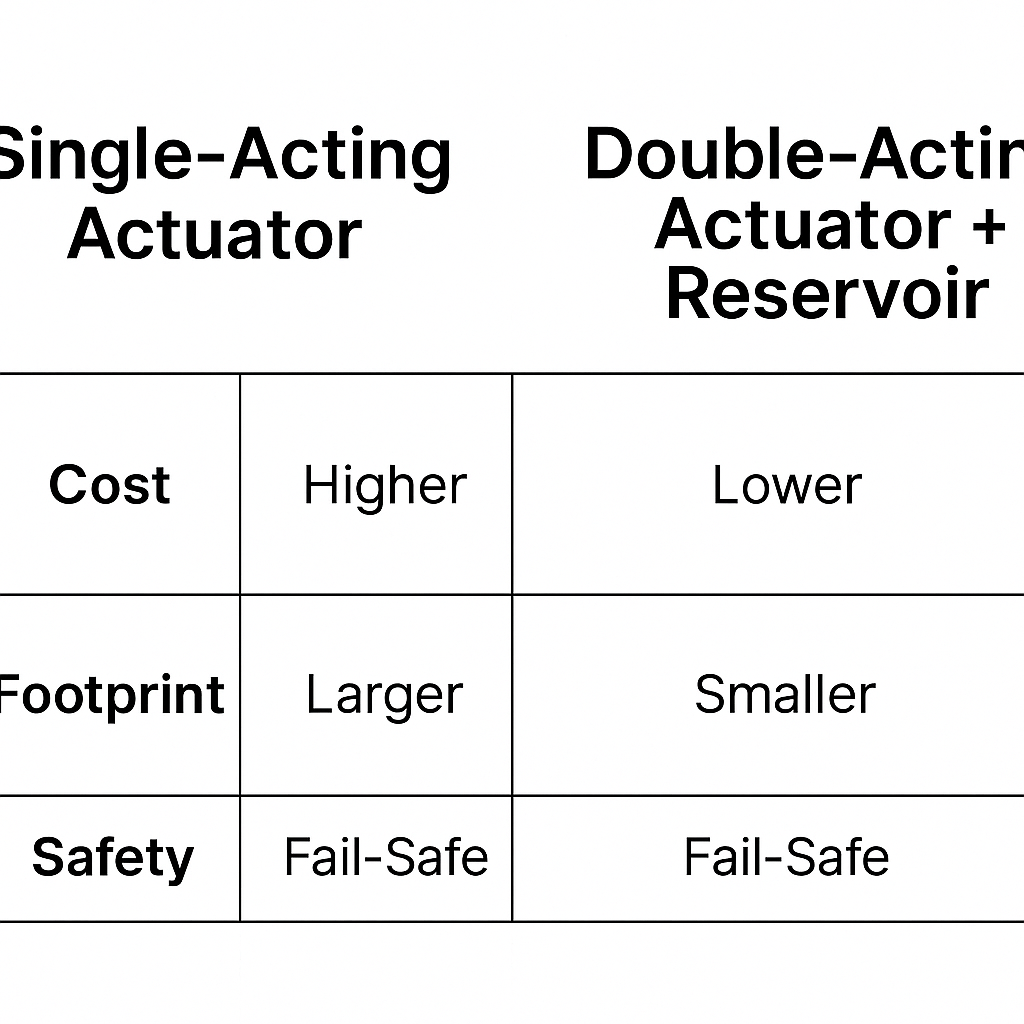

2.1 Cost and Space Efficiency

For large-diameter valves, using a single-acting actuator would require an oversized cylinder, leading to excessive cost and space requirements.

By combining a double-acting actuator with an air reservoir, the system can simulate the functionality of a single-acting actuator, achieving the same fail-safe capability at a lower cost and with reduced footprint.

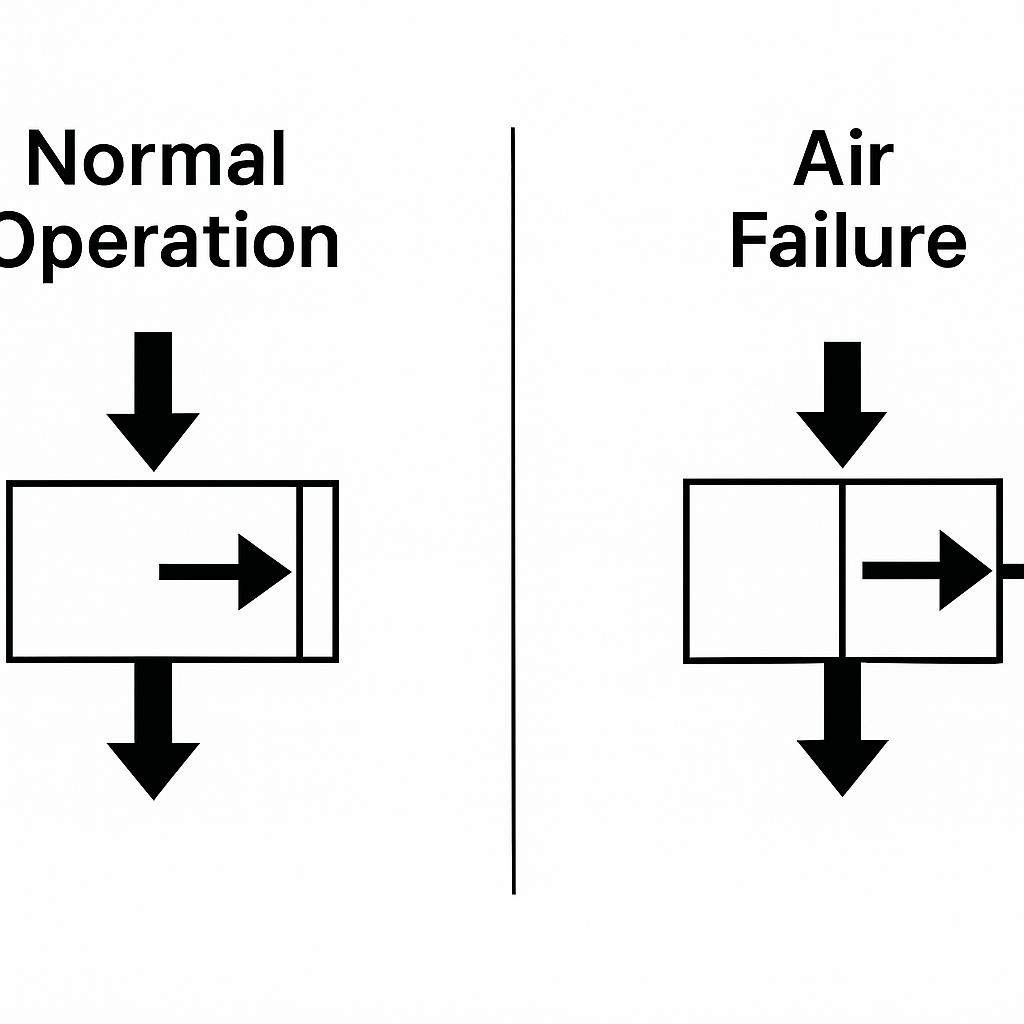

2.2 Fail-Safe Operation

If the main compressed air supply fails, the reservoir provides a backup air source, allowing the valve to reach the designated safe position (fully open or fully closed).

This ensures process continuity and safety until the system is restored.

2.3 Improved Stability and Precision

The reservoir acts as a buffer and damper, reducing pressure fluctuations, pulsations, and vibration in the pneumatic circuit.

This stabilizes actuator movement and enhances overall control accuracy.

3. How to Connect the Air Reservoir

The air reservoir must be connected to the actuator chamber that drives the valve to its fail-safe position. A typical configuration for a double-acting actuator with reservoir includes:

AF: Air filter and regulator

SV: Solenoid valve (2-position, 5-port)

AB: Air-operated valve

LV: Lock valve

QB: Air reservoir

CV: Check valve

SUP: Compressed air supply

3.1 Operating Conditions

| Operating Condition | Valve State | Role of Air Reservoir |

|---|---|---|

| Normal Operation | Solenoid energizes/de-energizes to open or close valve | Idle (standby) |

| Power Loss Only | Depends on solenoid design; valve may stay open or closed | Not active |

| Air Supply Loss Only | Reservoir discharges air to actuator | Drives valve to fail-safe position |

| Power + Air Loss | Valve position depends on piping design (open or closed) | Provides limited air until pressure depletes |

4. Considerations for Valve Action Mode

When selecting air-to-open (fail-close) or air-to-close (fail-open) action, process safety should be the first priority:

Air-to-Open (Fail-Close):

Suitable for fuel supply valves of furnaces; when air supply is lost, the valve closes to prevent overheating or explosion.Air-to-Close (Fail-Open):

Used for safety-critical liquid level control valves in fertilizer plants, ensuring that vessels are not overfilled during emergencies.Media Properties:

For crystallizing media, fail-close action prevents clogging; for heat exchanger control, fail-open may protect against overheating.Process Continuity vs. Product Quality:

In distillation towers, feed valves are usually fail-close (stop feed if no air), while reflux valves may be fail-open (maintain circulation).

5. Conclusion

Equipping pneumatic valves with an air reservoir provides a cost-effective, space-saving, and safety-enhancing solution, especially for large valves. The reservoir ensures:

Fail-safe positioning during air supply loss

Reduced vibration and pressure pulsation

Improved process stability and reliability

When designing and installing such systems, correct connection methods and careful selection of valve action mode are critical to ensure safety and operational efficiency.