Have you ever noticed that when installing a new steam pipeline, we specifically request that the flow orifice plate not be installed? You might wonder, why is this necessary? Let’s dive into the reasons behind this requirement.

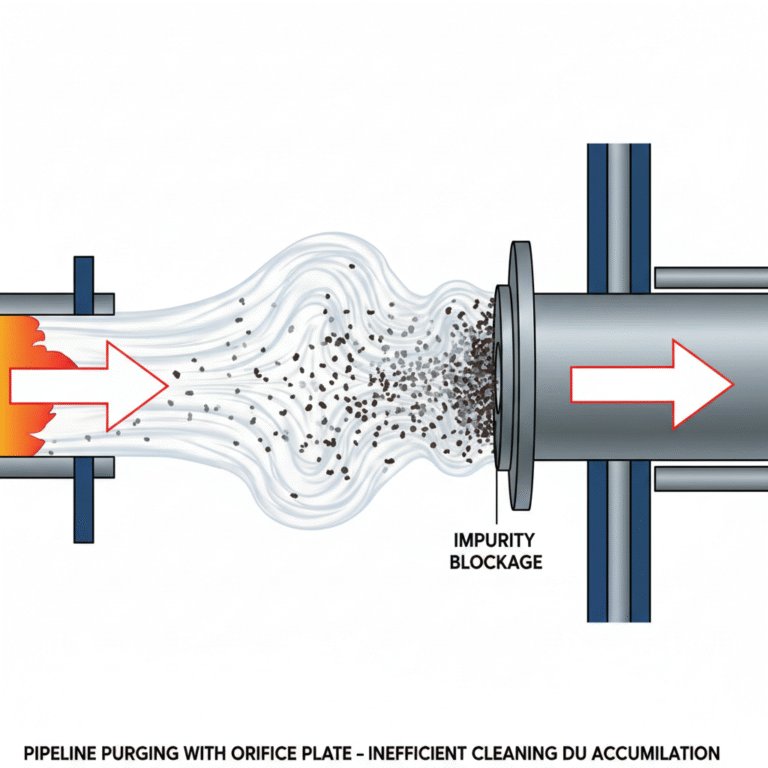

1. The Small Diameter of the Flow Orifice Plate Can Hinder Purging Effectiveness

The internal diameter of a flow orifice plate is typically smaller than that of the steam pipeline. If the flow orifice plate is not removed before purging the pipeline, various impurities within the pipeline can accumulate near the orifice plate. This accumulation can obstruct the purging process, making it difficult to clean the pipeline thoroughly and quickly. Effective purging relies on an unobstructed flow of steam, and any blockage near the orifice plate can impede this, leading to an inefficient cleaning process.

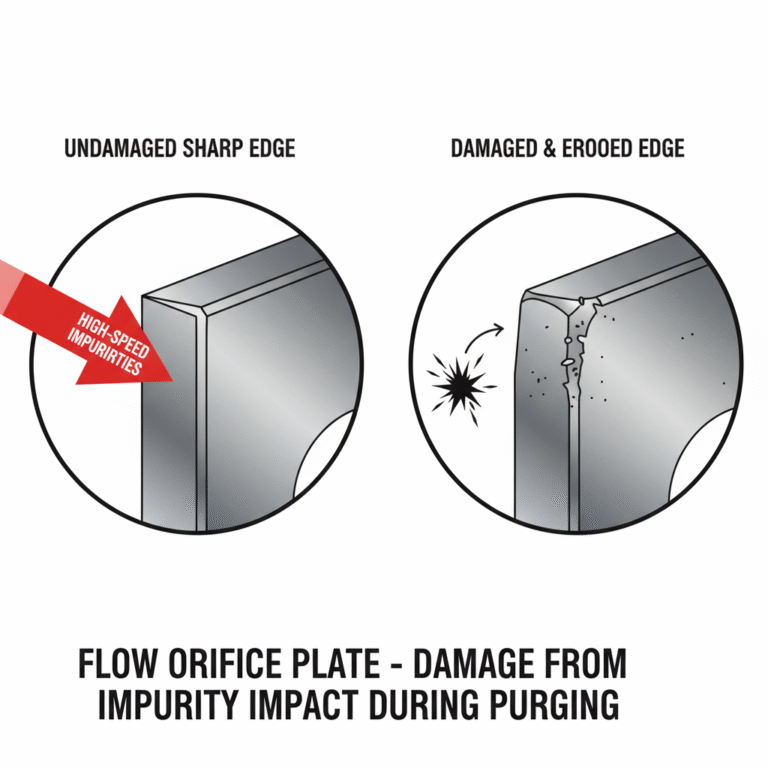

2. The Sharp Edge of the Orifice Plate Can Be Damaged

Flow orifice plates are precision-made, with the inlet side usually featuring a sharp, right-angle edge. If the orifice plate is left in place during the purging process, high-speed impurities and debris flowing through the pipeline can collide with the sharp edge. This can cause significant damage to the edge, affecting its shape and precision. As a result, the orifice plate may no longer provide accurate readings of the steam flow, compromising its measurement capabilities.

3. Significant Flow Measurement Error During Purging

The primary purpose of a flow orifice plate is to measure steam flow accurately under specific pressure and temperature conditions. However, during pipeline purging, the steam pressure and temperature are significantly lower than the conditions the orifice plate was designed to operate under. Under these circumstances, the flow meter will provide a much higher reading than the actual flow rate, resulting in a large measurement error that cannot be relied upon.

4. Best Practices for Installing Orifice Plates

To ensure optimal performance and accuracy, it’s best practice to delay the installation of the flow orifice plate until after the steam pipeline has been purged successfully. If the orifice plate has already been installed, it should be removed before purging and reinstalled once the pipeline has been properly cleaned.

Conclusion

The removal of flow orifice plates before steam pipeline purging is essential for ensuring the effectiveness of the cleaning process, protecting the integrity of the orifice plate, and avoiding inaccurate flow measurements. By following these best practices, you can ensure a more efficient installation and reliable steam flow measurement in your system.

Expanded Considerations

While the reasons for removing flow orifice plates before purging are relatively straightforward, it’s important to consider the broader impact this practice can have on the longevity of your equipment and the overall efficiency of your steam system. By preventing damage to your orifice plate and ensuring accurate measurements post-purge, you can save time, money, and reduce the risk of future maintenance issues.

Furthermore, the practice of removing orifice plates during purging is not just applicable to steam pipelines. It’s a good idea to apply this logic to other systems that rely on flow measurement devices. In any case where you are working with pressurized systems, removing delicate instruments before aggressive fluid flows can protect them from irreversible damage and ensure the accuracy of your readings moving forward.