1. Background and Standard Requirement

In the petrochemical industry, design standards directly affect operational safety and reliability.

According to SH/T 3005-2016 “Specification for Selection and Design of Petrochemical Automation Instruments”, clause 10.3.6.8 states:

“A manual valve shall be installed in the air line of a pneumatic actuator. By operating this manual valve on site, the actuator shall be able to close the valve. This manual valve shall be protected with a lead seal.”

During inspections, experts often demand that enterprises add lead seals to the manual shut-off valve on actuator air lines, requiring that closing the manual valve must ensure complete valve closure.

But is this technically feasible?

2. Practical Issues with Implementation

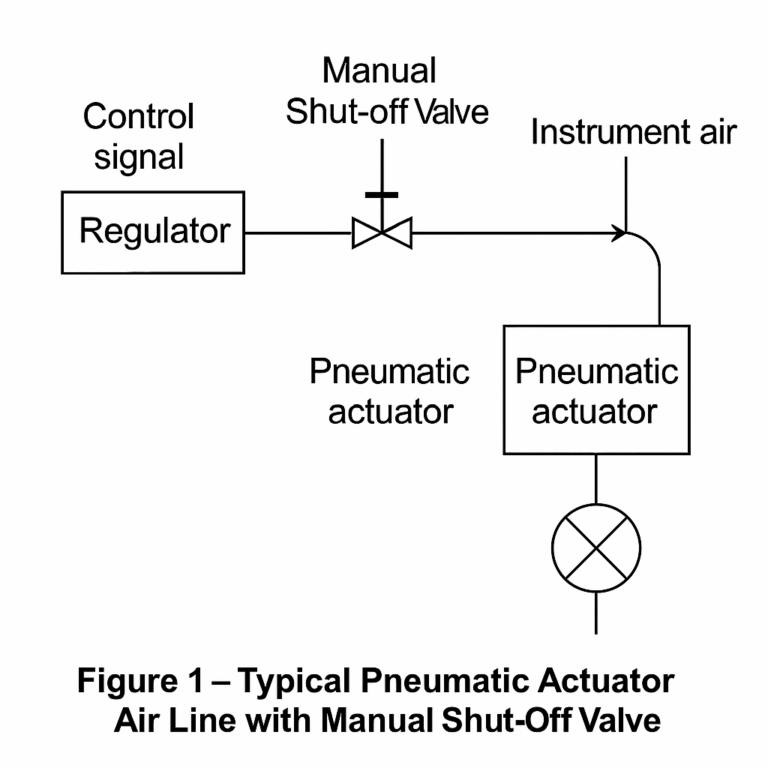

2.1 Structure of Manual Shut-Off Valves

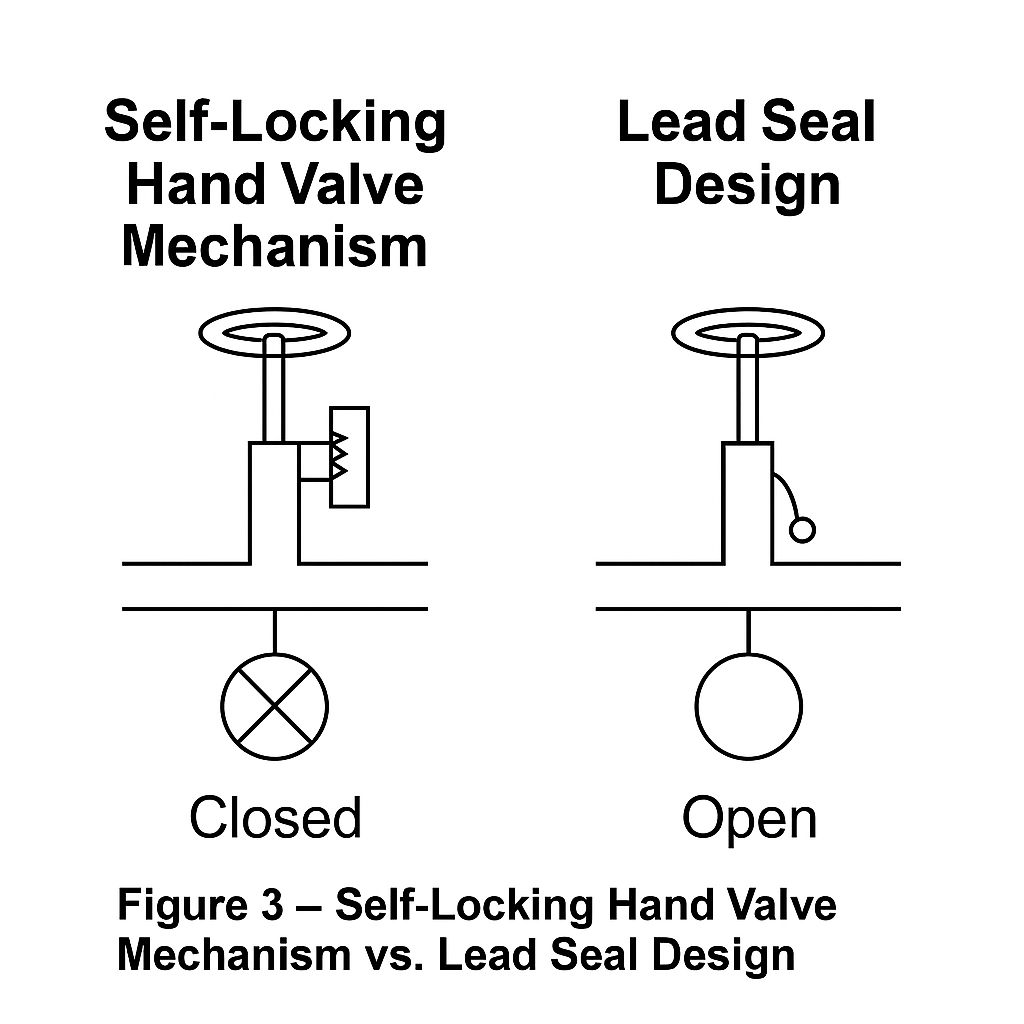

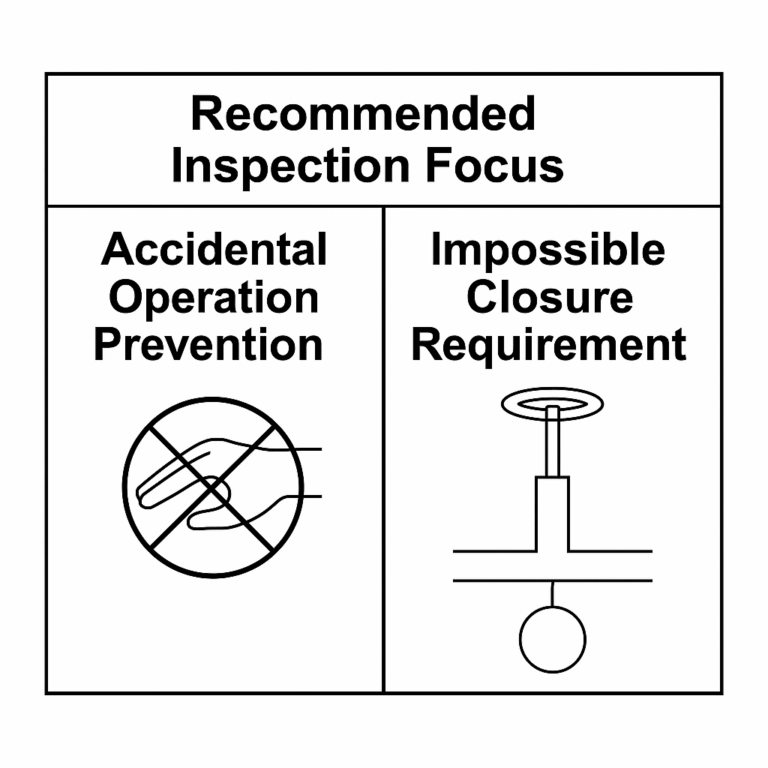

Typical hand-operated air shut-off valves do not have structural provisions for lead sealing.

In many cases, the valves already include a self-locking design, which can effectively prevent accidental operation.

2.2 Valve Behavior After Air Supply Shut-Off

Closing the air line manual valve does not immediately cause the valve to open or close.

On-off valves (e.g., pneumatic cylinder cut-off valves):

Unless an emergency interlock is triggered, cutting off the supply air will not exhaust the cylinder chamber. The valve remains in its last position.Control valves (e.g., pneumatic diaphragm valves):

Unless the positioner is adjusting, air trapped in the chamber is not vented. Closing the hand valve simply freezes the valve at its current opening.

Thus, valve closure cannot be guaranteed simply by operating the hand valve.

3. Safety Design Considerations

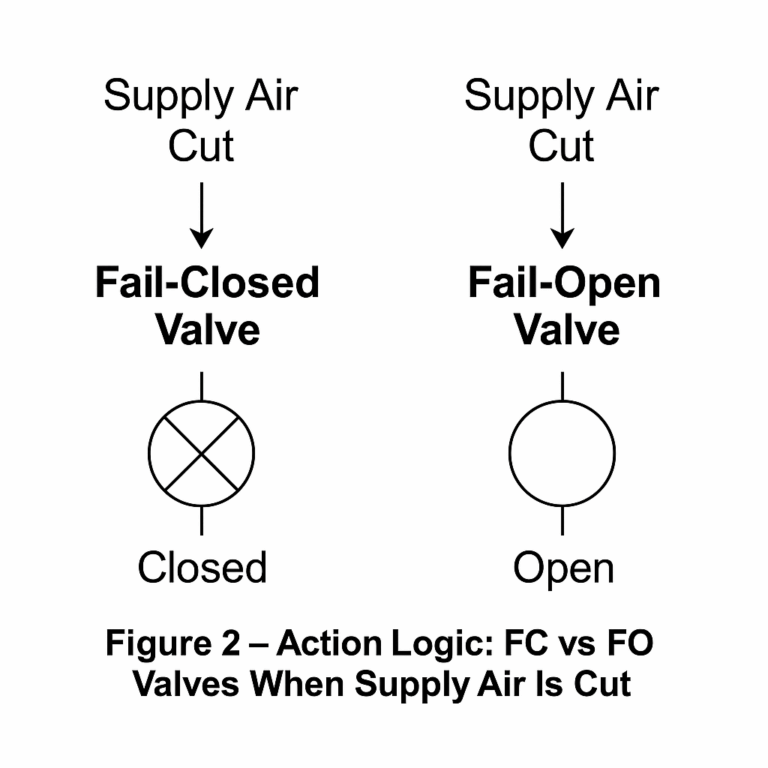

Modern control valves and on-off valves are designed with fail-safe modes (FO, FC, FLO, FLC, etc.).

Their action depends not only on instrument air but also on control signals from the DCS/ESD system.

Even if the supply air is cut, without a control command to vent the actuator chamber via the solenoid or positioner, the valve remains in place.

Therefore, the requirement that “the valve must close via the hand-operated air valve” is structurally and functionally impossible.

4. Root Cause of the Standard Clause

Discussions with the drafting committee reveal that the original intention of the clause was:

To prevent accidental operation of the hand valve during construction or inspection,

Avoiding unnecessary loss of actuator air supply that could lead to unintended process disturbances.

The intention was safety, but the wording of the clause is flawed—its operational requirements cannot be executed across different valve types.

5. Recommended Approach for Compliance

Instead of rigidly demanding lead sealing, a more practical approach would be:

Utilize self-locking valve designs to prevent accidental operation.

Clarify fail-safe logic of each valve type (FO, FC, etc.) during design review and inspection.

Focus inspections on verifying that actuator air supply cannot be inadvertently interrupted, rather than enforcing an impossible closure requirement.

6. Conclusion

The requirement in SH/T 3005-2016 clause 10.3.6.8 is well-intentioned but technically unfeasible.

A manual shut-off valve on the air line cannot guarantee actuator closure.

Inspections should prioritize safety integrity and functional design, not rigid adherence to wording that does not reflect real operating conditions.

In short: Safety comes from system-level fail-safe design, not from adding a lead seal to a hand valve that cannot achieve its stated purpose.