Grounding is a critical aspect of safety design in industrial facilities—especially in environments that handle flammable or explosive materials such as petrochemicals. Among the many grounding practices, a widely adopted and even mandatory requirement is to equip storage tanks with two grounding wires.

But why two? This article explores the technical, regulatory, and safety reasons behind this practice.

1. Redundancy for Safety: Preventing Grounding Failure

In any industrial setting, the failure of a grounding system can have severe consequences. If a storage tank has only one grounding wire and it becomes corroded, loose, or damaged, the tank could lose its connection to the ground. This results in a floating potential, allowing static charges to accumulate unchecked on the tank surface.

If discharged suddenly—such as during product transfer or environmental changes—these static charges can generate sparks, which may lead to fire or explosion.

🔐 Dual grounding connections provide redundancy, ensuring that if one line fails, the other still maintains effective grounding.

2. Improved Static Electricity Dissipation

During loading or unloading of fluids, especially volatile hydrocarbons, static electricity is naturally generated due to the triboelectric effect and fluid friction. If not properly dissipated, these charges build up on the tank’s surface.

Using two grounding points helps:

Disperse charges more evenly across multiple paths;

Reduce the potential difference between surfaces;

Lower the risk of localized high-energy discharges.

This is particularly important when conducting bottom loading, rapid pumping, or blending operations, all of which can intensify static generation.

3. Compliance with International Standards and Codes

Many engineering standards explicitly require that fixed storage tanks have at least two separate grounding connections. For example:

China: GB 50074-2014 (Code for Design of Petroleum Depots)

USA: NFPA 77 (Recommended Practice on Static Electricity)

IEC: IEC 60079 series (Explosive atmospheres)

These standards aim to prevent accidents through enforced engineering controls.

📌 In regulated industries, failure to follow this requirement could result in legal liabilities or shutdown by safety inspectors.

4. Minimizing Grounding Resistance

The grounding resistance of a single connection may be too high—especially in dry or sandy soil where conductivity is poor. Adding a second grounding wire:

Lowers overall grounding resistance through parallel connections;

Improves the effectiveness of current discharge;

Provides a more robust electrical connection to earth.

This is crucial in ensuring that static charges and fault currents are safely and rapidly dissipated.

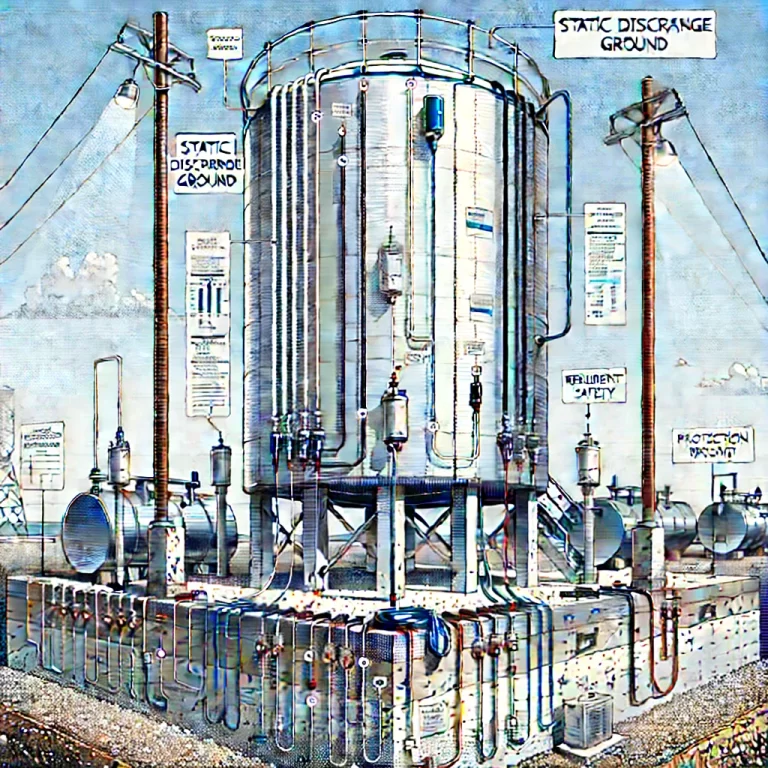

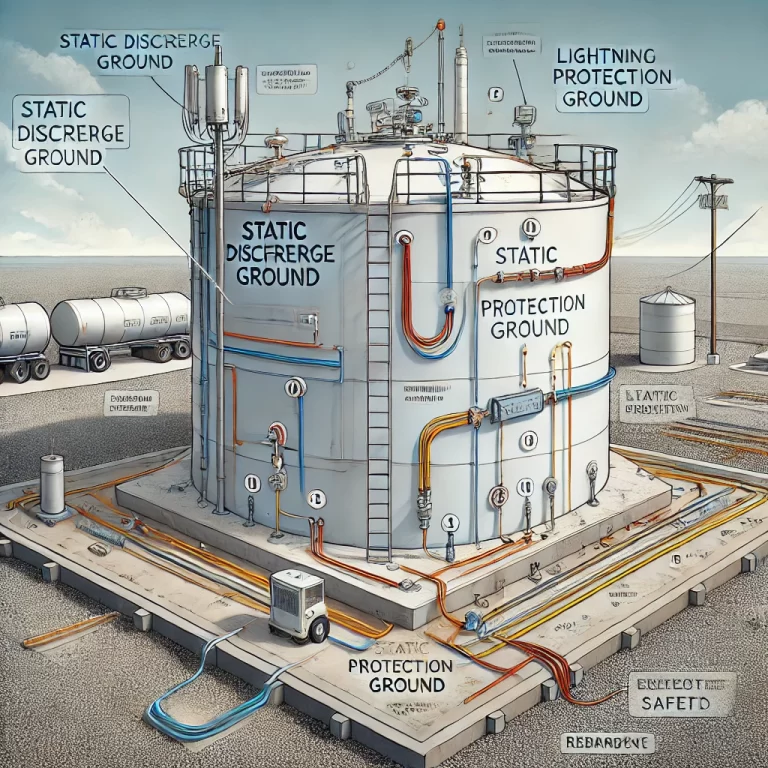

5. Functional Separation: Static Grounding vs. Lightning Protection

In some setups, one grounding connection is designated for static discharge, while the other is for lightning protection. Though both are eventually connected to a common grounding grid, separating their physical connection points can:

Reduce electromagnetic interference;

Prevent cross-current damage during lightning strikes;

Ensure system stability during transient surges.

This functional separation is sometimes adopted in hazardous areas or critical installations.

6. Routine Inspection and Reliability

Another practical benefit of having two grounding lines is during maintenance or testing. If one wire needs to be disconnected for inspection, the second wire still provides protection.

This increases system availability and helps meet the safety requirements of continuous operation facilities.

Conclusion

Equipping storage tanks with two grounding wires is not just a conservative design choice—it is a critical safety requirement based on decades of industrial experience, scientific understanding of static discharge, and international regulatory mandates.

The key benefits include:

Fail-safe operation through redundancy

Safer static discharge during loading/unloading

Legal and standards compliance

Lower grounding resistance

Support for both static and lightning protection

Improved maintainability

✅ For any facility dealing with flammable liquids, following this principle is essential to ensure safety, compliance, and operational continuity.