Modbus and ProfiNET represent different stages of development of industrial communications, each with its own advantages and disadvantages. Modbus is simple and easy to use, suitable for small systems; ProfiNET is efficient and stable, suitable for large and complex networks. Converting Modbus to ProfiNET can improve system performance and scalability.

In actual scenarios, the production line controller was upgraded to ProfiNET, which significantly improved the data transmission rate and stability, meeting the needs of modern industrial automation.

1. What is Modbus?

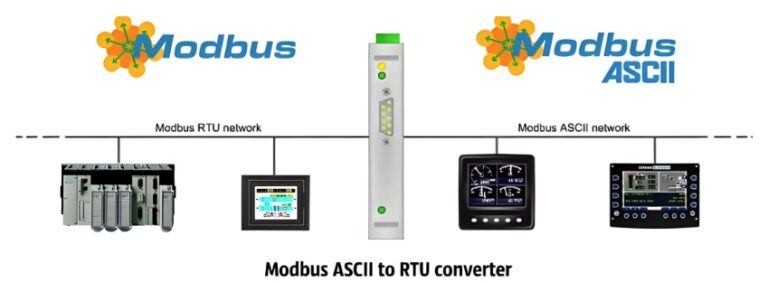

Modbus is an application layer protocol mainly used for device communication in the field of industrial automation. It supports multiple communication methods, including RS-232, RS-485 and Ethernet. The Modbus protocol is simple and easy to use, and can realize data exchange and remote control between devices. However, due to its early design, Modbus has some limitations in data transmission speed, security and scalability.

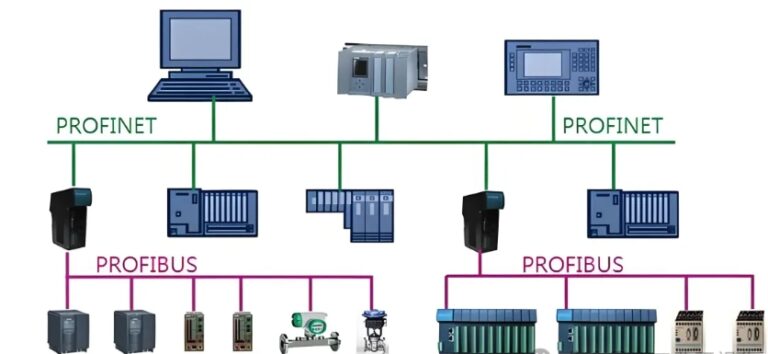

2. What is ProfiNET?

ProfiNET is an industrial Ethernet standard launched by the PROFIBUS user organization. It is based on Ethernet technology and provides high-speed, real-time data transmission capabilities. ProfiNET supports multiple communication mechanisms, including real-time Ethernet, motion control and distributed automation. Compared with Modbus, ProfiNET has higher data transfer rate, stronger security and better scalability.

ProfiNET is an industrial Ethernet standard launched by the PROFIBUS user organization. It is based on Ethernet technology and provides high-speed, real-time data transmission capabilities. ProfiNET supports multiple communication mechanisms, including real-time Ethernet, motion control and distributed automation. Compared with Modbus, ProfiNET has higher data transfer rate, stronger security and better scalability.

3. Advantages, disadvantages and usage scenarios

Advantages of Modbus:

Simplicity: The protocol is simple and easy to implement and maintain.

Cost-Effectiveness: Due to its ubiquity, the associated hardware and software costs are low.

Compatibility: Supports multiple communication methods and is compatible with multiple devices.

Disadvantages of Modbus:

Speed limitations: Data transfer speeds are relatively slow.

Insufficient security: Lack of advanced security mechanisms.

Limited scalability: It is difficult to support large-scale and complex automation systems.

Advantages of ProfiNET:

High-speed transmission: Based on Ethernet, it provides high-speed data transmission.

Security: Supports advanced security mechanisms such as end-to-end encryption.

Scalability: Suitable for large-scale and complex industrial automation systems.

Disadvantages of ProfiNET:

Cost: Initial investment may be higher than Modbus.

Complexity: The protocol is relatively complex and requires expertise to configure.

Scenes to be used:

Modbus is typically used for small or cost-sensitive projects, and those applications that do not require high-speed data transmission. ProfiNET is suitable for large-scale industrial automation projects that require high-speed, real-time communication and high security.

4. Scenario application

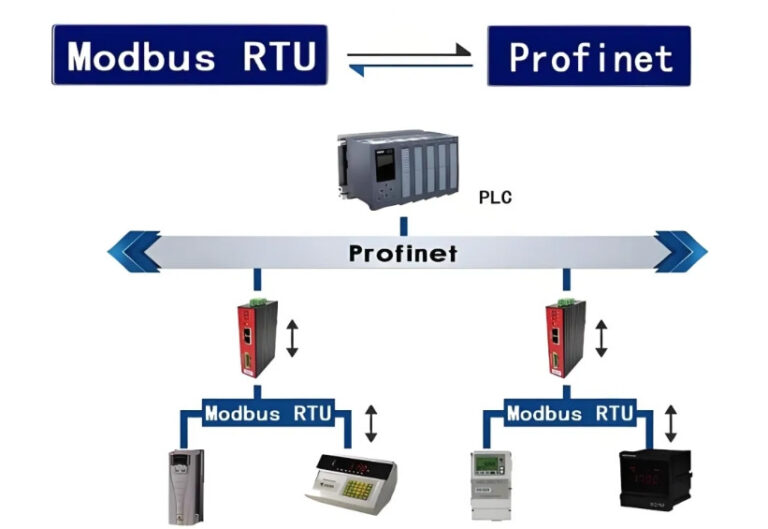

Assume that a manufacturing factory initially used a control system based on Modbus. As the production scale expanded and automation requirements increased, the original Modbus system could no longer meet the needs of high-speed data transmission and real-time control.

In order to solve these problems, the factory decided to upgrade to the ProfiNET system. During the upgrade process, they need to convert existing Modbus devices into ProfiNET compatible devices through gateways or adapters. For example, PLCs (programmable logic controllers) in factories originally communicated with sensors and actuators via Modbus. Now, by installing ProfiNET adapters, the PLCs are able to communicate with these devices at higher speeds and with greater security.

In addition, the factory also deployed ProfiNET switches to build a high-speed, reliable network infrastructure. With this conversion, the factory not only improves production efficiency but also enhances the system’s security and future scalability.