4 Engineering Purposes Behind This Design

In industrial piping systems, it is common to see a curved pipe section—often referred to as a siphon tube, gauge bend, or pigtail—installed below a pressure gauge. While it may seem like a minor detail, this bend serves several critical engineering purposes that protect the gauge and improve system reliability.

1. Dampens Pressure Pulsation – Extends Gauge Lifespan

Principle:

When fluid or gas flows through a pipeline, pressure surges or pulsations can occur due to valve operation, pump cycling, or rapid process changes. The bend introduces a damping effect by increasing flow resistance and buffering the transmission of pressure waves.

Benefits:

Prevents pointer oscillation and vibration damage

Reduces wear on internal components such as Bourdon tubes and gears

Enhances reading stability and accuracy

2. Isolates High-Temperature Media – Prevents Thermal Damage

Principle:

When measuring high-temperature media (e.g., steam or hot liquids), direct exposure can damage sensitive components inside the gauge. The curved pipe provides a longer path, allowing the medium to cool down before reaching the gauge.

Real-world Application:

In steam systems, condensate often collects in the bend, forming a water seal that physically isolates the hot steam from the gauge, serving as an effective thermal barrier.

3. Enables Safer Maintenance – Minimizes Media Leakage

Structural Advantage:

The bend creates a buffer zone between the gauge and the main line. When maintenance is needed, the valve (e.g., needle valve) before the bend can be closed to safely remove or calibrate the gauge without media discharge.

Leak Prevention:

Curved connections allow for better sealing (threaded or welded), reducing the risk of leakage often encountered in straight pipe connections—especially with high-pressure or corrosive media.

4. Provides Additional Functional Benefits

Particle Separation:

In systems with suspended solids, the bend helps trap debris before it enters the gauge, avoiding blockage or abrasion.Pressure Stabilization:

Helps to stabilize static pressure at the gauge inlet by compensating for minor fluctuations due to velocity changes.

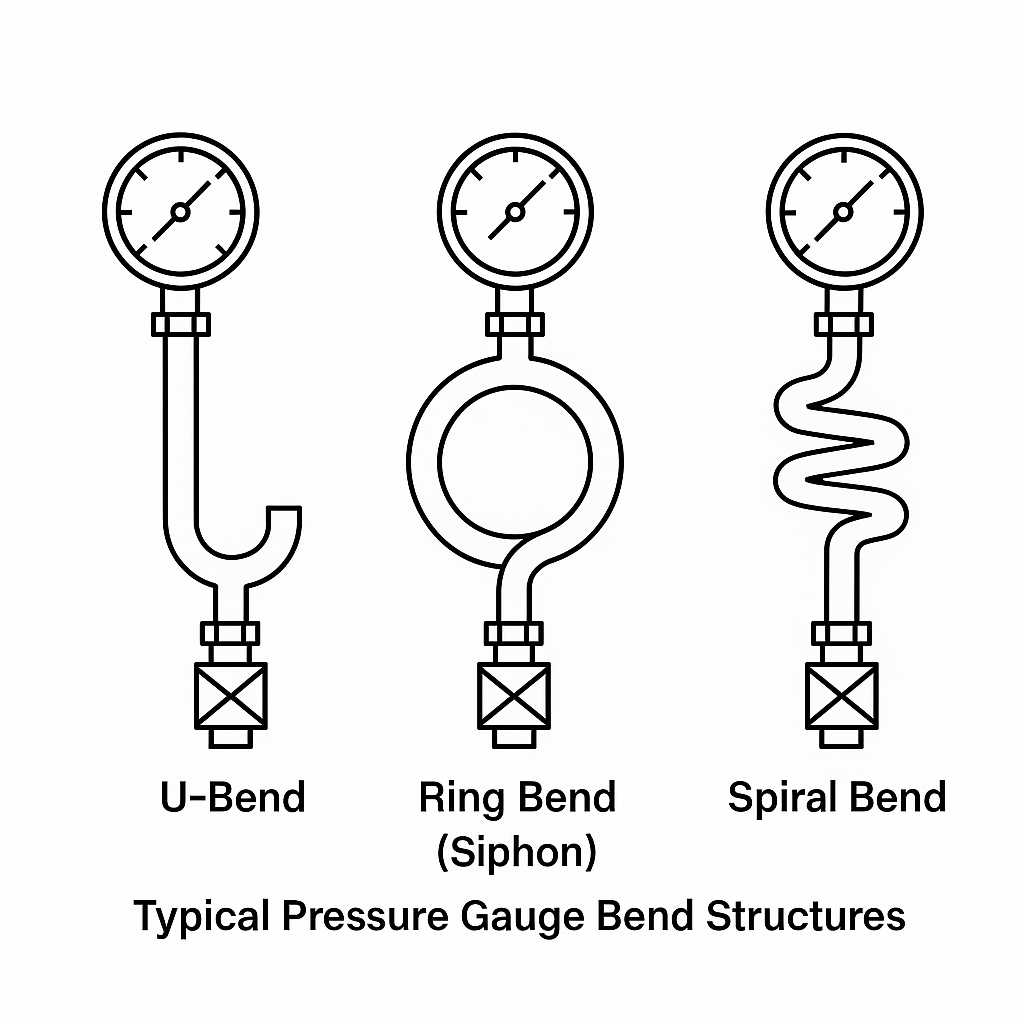

🔍 Common Bend Types and Application Matrix

| Type | Structural Feature | Recommended Media | Typical Applications |

|---|---|---|---|

| U-Bend (U Tube) | Simple U-shaped curve | Steam, hot liquids | Steam boilers, thermal pipelines |

| Ring Bend (Siphon) | Closed circular loop | Steam, compressed gas | High-pressure steam lines, compressors |

| Spiral Bend | Coiled spiral tube | Viscous or corrosive fluids | Chemical plants, petroleum pipelines |

✅ Conclusion

Installing a bent pipe section below a pressure gauge is a proven engineering solution that ensures reliable pressure readings while protecting the instrument from pressure spikes, high temperature, and maintenance risks. For optimal results:

Match the bend type to the media conditions (temperature, viscosity, pressure)

Always install with an isolation valve (needle valve or ball valve)

Use appropriate sealing methods for harsh or hazardous environments