In the paper manufacturing industry, controlling environmental conditions—especially temperature and humidity—is a critical factor that directly impacts product quality, stability, and production efficiency. The sensitivity of paper to moisture and temperature changes makes real-time environmental monitoring essential during both production and storage. Here’s why:

1. Paper Composition and Hygroscopic Properties

Paper is primarily composed of plant-based cellulose fibers, which are highly hygroscopic in nature. This means that paper readily absorbs or releases moisture depending on the surrounding air humidity. Any fluctuation in temperature or humidity can cause changes in the physical dimensions and surface characteristics of the paper, such as warping, curling, or loss of flatness. These changes can significantly impact print quality, mechanical processing, and final product consistency.

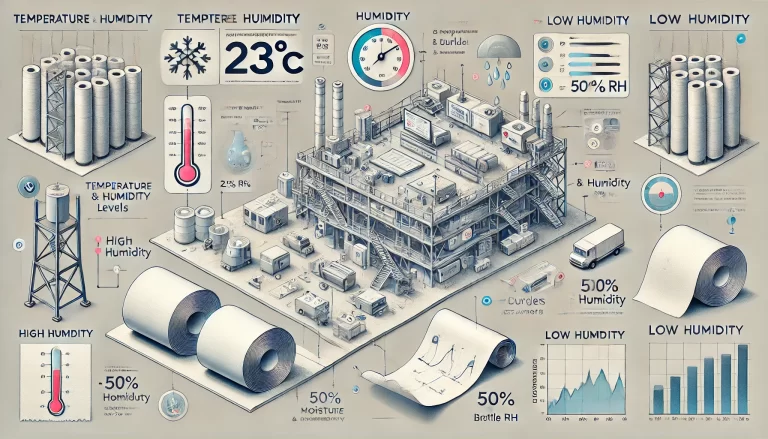

2. Effects of Excessive Humidity

When stored or processed in high-humidity environments, paper absorbs moisture from the air. This absorption leads to an increase in the paper’s length and thickness, often resulting in waviness, unevenness, and loss of structural integrity. Such deformation not only affects the aesthetic appearance but can also cause misfeeds or jams in high-speed printers or cutting equipment.

3. Consequences of Low Humidity

On the other hand, in excessively dry conditions, the paper tends to lose moisture unevenly—typically starting from the edges and moving toward the center. This results in edge curling, where the sides of the paper lift upward. Furthermore, low humidity environments can degrade the mechanical strength and flexibility of paper, making it brittle and more susceptible to cracking or tearing during handling.

4. Temperature’s Indirect Influence on Humidity Control

While it may seem that temperature plays a lesser role compared to humidity, its impact is in fact profound due to its direct relationship with relative humidity (RH). Even if the absolute moisture content in the air remains constant, a rise in temperature reduces RH, and a drop in temperature increases it. For example, saturated air at 0°C heated to 23°C will see its relative humidity fall below 22%, dramatically altering the paper’s moisture balance. This temperature-humidity interplay must be carefully managed, particularly in seasonal climates or facilities with fluctuating HVAC performance.

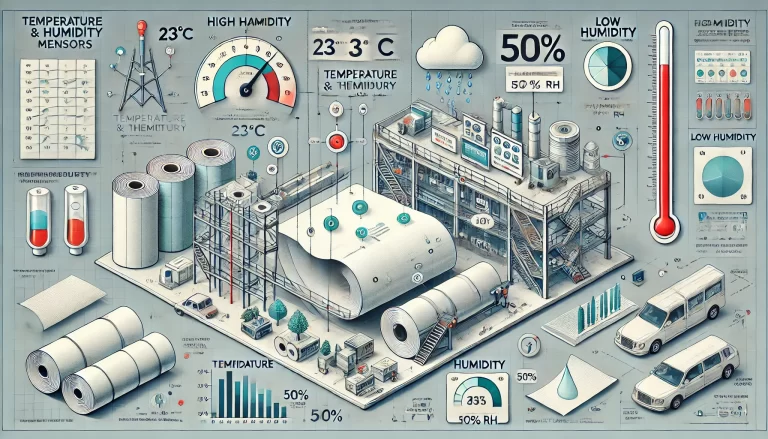

5. Recommended Environmental Conditions for Paper Production

To ensure optimal performance, stability, and printability, the recommended environmental conditions for paper production and storage are:

- Temperature: 23°C ± 1°C

- Relative Humidity: 50% RH ± 2%

Maintaining these parameters consistently helps preserve the dimensional stability and mechanical properties of paper throughout its lifecycle—from manufacturing to end use.

6. The Role of Temperature and Humidity Sensors

Advanced temperature and humidity sensors are indispensable tools in modern paper production environments. These sensors provide real-time data that enables precise environmental control. Key advantages of using high-quality sensors include:

- High measurement accuracy

- Low temperature drift

- Fast response time

- Excellent long-term stability

By integrating these sensors into the production process, manufacturers can reduce waste, minimize defects, and improve overall product consistency.

Conclusion

Environmental control is not just a supporting factor in paper production—it is a core component of quality assurance. Through effective temperature and humidity monitoring, manufacturers can maintain product quality, enhance operational efficiency, and meet the stringent requirements of modern printing and packaging industries.