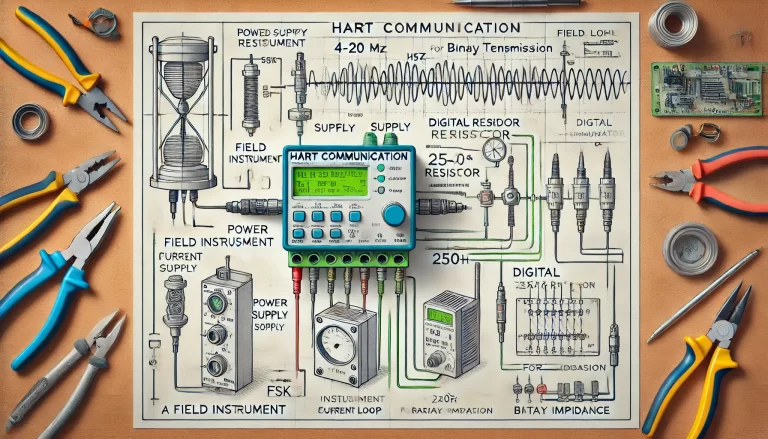

In the field of industrial automation, the choice of signal transmission is crucial for ensuring accurate and reliable communication between sensors, controllers, and actuators. Among the various signal transmission methods available, the 4-20 mA current signal is widely preferred over voltage signals (such as 0-10V or 0-5V) due to several inherent advantages. This article explores the reasons behind the widespread adoption of 4-20 mA current signals in industrial automation systems.

1. Immunity to Electrical Interference

Industrial environments are typically filled with electromagnetic interference (EMI) and radio frequency interference (RFI) generated by motors, transformers, high-voltage lines, and other equipment. Current signals are inherently less susceptible to these interferences compared to voltage signals. This is because current remains constant throughout a closed-loop circuit, whereas voltage can fluctuate due to external electromagnetic fields.

2. Long-Distance Signal Transmission

When transmitting signals over long distances, voltage signals experience significant losses due to cable resistance and other factors. The voltage drop across long cables can distort the transmitted signal and lead to inaccurate readings. In contrast, the current in a 4-20 mA loop remains consistent regardless of resistance variations, ensuring accurate signal transmission even over long distances.

3. Detection of Signal Integrity and Faults

A major advantage of using the 4-20 mA standard is its ability to detect system faults, such as wire breaks or sensor failures. The signal range of 4-20 mA is intentionally designed so that any current below 4 mA can indicate an open circuit or failure, making it easy for operators to identify problems. If a 0-20 mA system were used, distinguishing between a true zero reading and a fault condition would be difficult.

4. Improved Signal-to-Noise Ratio

The 4-20 mA signal offers a better signal-to-noise ratio compared to voltage-based systems. Since current signals are less affected by electrical noise, the measurement accuracy is enhanced, especially in harsh industrial environments where various noise sources can interfere with voltage signals.

5. Industry Standard and Compatibility

The 4-20 mA current loop is an industry standard, making it universally compatible with a wide range of industrial equipment and controllers such as Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and data acquisition systems. The standardized signal ensures seamless integration across different manufacturers and systems.

6. Two-Wire Loop Power Capability

In many applications, 4-20 mA loops can be powered using just two wires, which simplifies wiring and reduces installation costs. These two wires carry both the power supply and the measurement signal, allowing for streamlined implementation, especially in remote or hazardous locations where minimal wiring is desired.

7. Safety in Hazardous Environments

Many industrial applications, such as those in the chemical and oil & gas industries, operate in hazardous environments where safety is a critical concern. The low energy levels in a 4-20 mA loop reduce the risk of sparks, which could ignite flammable substances, making it suitable for intrinsically safe applications.

8. Ease of Calibration and Linear Scaling

The 4-20 mA range provides an easy way to calibrate and scale measurements, with 4 mA typically representing the minimum value (zero) and 20 mA representing the full-scale measurement. This linear relationship simplifies calculations and reduces the likelihood of errors in data interpretation.

9. Cost-Effective and Reliable

While voltage signal systems may require additional conditioning and compensation for resistance changes, 4-20 mA systems are inherently more reliable and cost-effective in the long run. The simplicity of the current loop design reduces maintenance and troubleshooting efforts.

Conclusion

The 4-20 mA current signal has become the preferred choice for industrial automation due to its reliability, accuracy, and resilience to environmental factors. Its advantages, including immunity to interference, long-distance transmission capability, fault detection, and compatibility with industry-standard equipment, make it an ideal choice for a wide range of industrial applications. While voltage signals may still be used in specific applications, the robustness and dependability of 4-20 mA ensure its continued dominance in the automation sector.