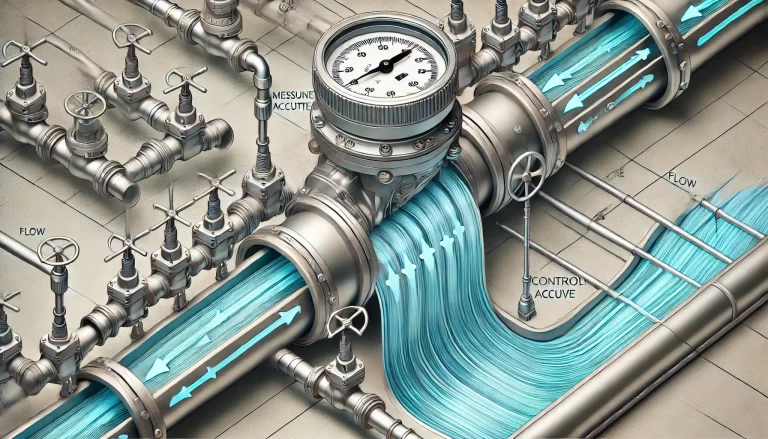

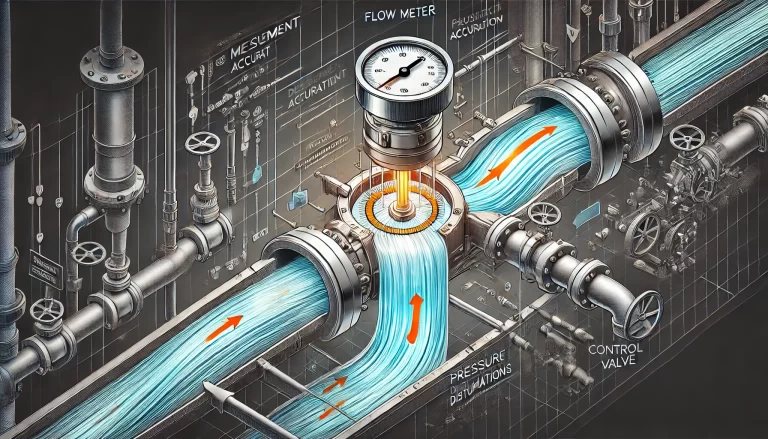

In a piping system, it is common practice to install a flow meter upstream of a control valve. This arrangement is generally preferred due to several key reasons:

1. Ensuring Measurement Accuracy

The primary reason for placing the flow meter before the control valve is to ensure accurate flow measurements. Control valves, when adjusted, create disturbances in the flow, such as changes in velocity, pressure fluctuations, or turbulence. If the flow meter is installed downstream of the control valve, these disturbances can result in inaccurate readings. By positioning the flow meter upstream, where the fluid flow is more stable and less affected by valve adjustments, the measurements become more reliable.

2. Protecting the Flow Meter from Damage

Control valves can induce sudden changes in flow rate or pressure when they open or close, which can potentially damage the flow meter if it is located downstream. Sudden pressure surges or turbulence could cause wear or reduce the lifespan of sensitive flow measurement devices. Installing the flow meter upstream, where the flow remains more consistent, helps protect it from these adverse effects and prolongs its operational life.

3. Enhancing Control System Efficiency

In a control system, the timely and accurate feedback of flow data is critical for efficient regulation. If the flow meter is placed after the control valve, the response time of the system might be delayed due to fluctuating flow conditions downstream. This could lead to slower or less precise adjustments by the control system. When the flow meter is installed before the valve, the system receives real-time, accurate flow data, allowing for quicker and more precise valve adjustments. This improves the overall performance and responsiveness of the control system.

Conclusion

Installing the flow meter before the control valve is a standard engineering practice that helps to ensure measurement accuracy, protect the flow meter from flow-induced disturbances, and improve the efficiency of control systems. By maintaining a stable flow condition for measurement, this setup supports the reliable operation of the system and prolongs the life of the flow measurement instruments.