In the field of industrial instrumentation, it’s common for engineers and suppliers to request detailed parameters for flow and level instruments, but not for pressure and temperature devices. At first glance, this might seem inconsistent—but there are sound technical and practical reasons behind this practice.

In this article, we’ll explore why flow and level measurements require more comprehensive information during the selection process, while pressure and temperature instruments usually do not.

✅ 1. Measurement Complexity: Flow and Level Are Multivariable Systems

Flow and level measurement is inherently more complex than pressure or temperature monitoring. These instruments are influenced by multiple interacting variables:

🟢 Flow Meter Selection Depends on:

Medium type (liquid, gas, steam, slurry)

Flow range

Pipe diameter

Pressure and temperature conditions

Viscosity or density

Presence of solids, gas bubbles, or magnetic/electrical properties

Required accuracy, output signal, installation orientation

🟢 Level Measurement Depends on:

Tank geometry and height

Medium density and volatility

Foam, steam, or vapor presence

Internal obstructions (agitators, baffles)

Pressure or vacuum inside the vessel

Open or closed tank configuration

➡️ Because of this complexity, flow and level instruments require a full set of recommended parameters to ensure correct selection and reliable performance.

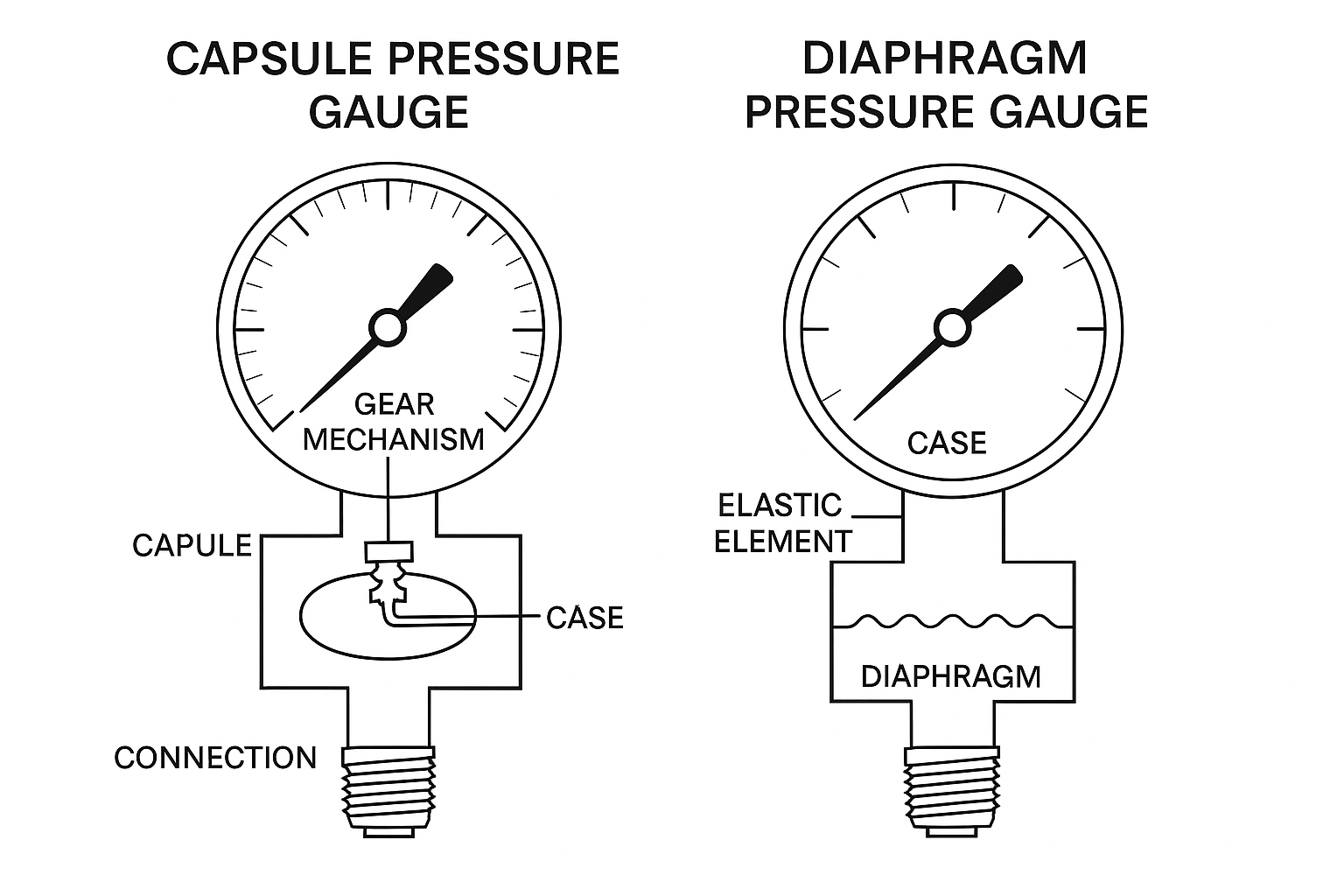

✅ 2. Pressure and Temperature Are Simpler Point Measurements

In contrast, pressure and temperature are point measurements, meaning they represent a physical quantity at a specific location.

🔴 Pressure Instruments Typically Need:

Measurement range (e.g., 0–10 bar)

Type (gauge, absolute, or differential)

Process connection

Output signal

Media compatibility

🔴 Temperature Sensors Typically Need:

Measuring range

Sensor type (RTD or thermocouple)

Insertion length

Process connection and sheath material

Output (if using a transmitter)

➡️ With fewer influencing factors and simpler working conditions, standard models of pressure and temperature instruments often suffice for most applications without needing a long list of input data.

✅ 3. Instrument Diversity: Flow and Level Have Dozens of Measurement Principles

The number of technologies available for measuring flow and level is far greater than for pressure or temperature.

| Measurement | Variety of Types | Examples |

|---|---|---|

| Flow | 10+ | Electromagnetic, Vortex, Coriolis, DP, Ultrasonic, Turbine |

| Level | 5–8 | Radar, Guided Wave Radar, Ultrasonic, Float, Differential Pressure |

| Pressure | 2–3 | Gauge, Absolute, Differential |

| Temperature | 2 | RTD, Thermocouple |

➡️ The wide diversity in principles means each flow or level meter has a unique set of conditions under which it works best.

✅ 4. Installation Sensitivity Is Higher for Flow and Level

Both flow and level measurement devices are highly dependent on installation conditions.

Examples:

A flowmeter installed near a pump or elbow without sufficient straight pipe may give inaccurate readings.

A radar level transmitter installed in a narrow, foamy tank may lose signal if not configured correctly.

Incorrect installation height or flange orientation can lead to costly performance issues.

➡️ That’s why detailed recommended parameters help avoid installation mismatches and ensure accurate and stable measurements.

✅ 5. Standardization in Pressure and Temperature Devices

Modern pressure and temperature transmitters are highly standardized, often modular, and compatible across a range of industries.

This means:

Fewer application-specific requirements

Easier model selection based on catalog ranges

Better interchangeability across projects

➡️ That’s why pressure and temperature instruments usually require only a simple specification sheet, while flow and level instruments may need a dedicated application form or checklist.

✅ Conclusion

| Category | Flow & Level | Pressure & Temperature |

|---|---|---|

| Complexity | High (Multivariable) | Low (Point-based) |

| Installation Sensitivity | High | Medium to Low |

| Instrument Variety | Very Broad | Narrow |

| Need for Application Data | Essential | Optional / Minimal |

| Risk of Misapplication | High Without Full Parameters | Low |

So next time you’re asked to provide a flow or level instrument quotation, don’t be surprised when the engineer requests a “recommended parameter sheet”. It’s not bureaucracy—it’s best practice.