In petrochemical plants, level measurement in storage tanks may seem simple, but when problems arise, the impact on safety and production cost can be significant.

⚠️ The Traditional Approach: One Tank, One Gauge

To minimize cost, many facilities traditionally use a single level transmitter (e.g., radar or magnetic flap type) per tank. However, as production scales up, more issues arise in practice—such as sudden instrument failures or inaccurate readings after long operation hours.

If there’s only one level instrument and it malfunctions, the production line must shut down immediately for emergency repair, causing severe downtime and economic loss.

✅ The Smarter Strategy: Dual-Level Configuration

Several clients have adopted a “dual-level configuration” in critical tanks, based on technical advice from Zero Instrument. The results have been highly positive.

What is Dual-Level Configuration?

It means installing two types of level instruments in the same tank. Here’s how it works:

Primary Instrument

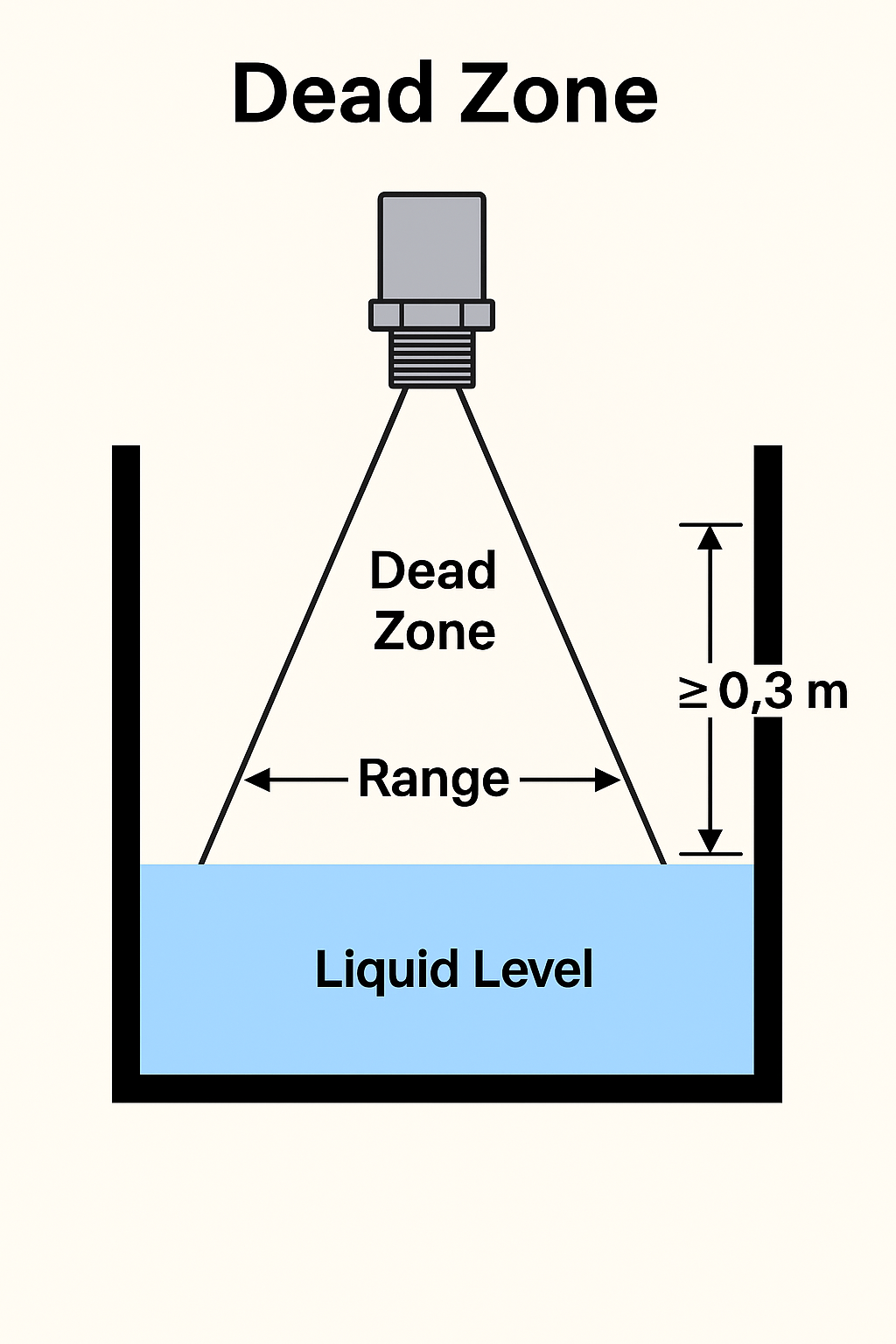

Typically a radar or ultrasonic level transmitter—chosen for its high accuracy, stability, and low maintenance. It serves as the main measurement source under normal conditions.Backup Instrument

Usually a simple and reliable device, like a tuning fork switch, magnetic flap level gauge, or float level transmitter. It activates when the primary instrument fails or shows abnormal data.

These instruments are connected to separate control modules:

The primary device sends data to the DCS (Distributed Control System) for daily monitoring.

The backup device is wired to the SIS (Safety Instrumented System) to support safety interlocks and alarms in emergencies.

🛠 Case Study: Benzene Storage Tank

A chemical industry client adopted this setup:

Radar level transmitter as the primary device

Magnetic flap level gauge as the backup

In 2023, the radar gauge showed sudden signal spikes. The DCS system issued an alarm. Technicians cross-checked with the magnetic gauge, which confirmed that the actual level was normal. This eliminated the risk of a false leak alarm and prevented an unnecessary shutdown.

The client later praised Zero Instrument’s dual-level design and went on to order dozens more units as spare parts.

📌 Key Installation Tips

Install sensors at separate locations: Keep radar and magnetic gauges at least 0.5 meters apart to avoid signal interference.

Regular data cross-checking: Periodically compare primary and backup readings. Large discrepancies must trigger an inspection.

Routine backup verification: Ensure the backup device is functional in case of emergency activation.

💡 Cost vs. Value: The Financial Perspective

Initially, many companies resist the dual configuration, believing it increases capital cost unnecessarily. But in one project, a petrochemical client found that after a few years of operation, maintenance costs dropped by over 50%.

Why?

Lower accident and failure risk

Immediate fallback during emergencies

Less stress for maintenance teams

The upfront investment (20%–30% higher) was far outweighed by long-term savings.

📌 When Dual-Level Gauges Are Most Recommended

Not every tank needs a dual setup. But it’s highly recommended when:

The stored material is hazardous (toxic, explosive, etc.)

The liquid level is tied to safety interlocks

The material is expensive or requires high measurement accuracy

✅ Conclusion

“Dual-Level Configuration” has proven to improve safety and reduce unplanned downtime. As production facilities aim for higher reliability, this design has gained broad industry recognition.

For new construction or tank upgrades, Zero Instrument strongly recommends evaluating this configuration to enhance both safety and cost-efficiency.