Many may have noticed that when the pipe diameter is equal to or slightly larger than the flow meter’s measuring pipe diameter, the flow readings remain stable, and the flow coefficient is normal. Even if secondary flow occurs, the impact on the instrument is minimal. However, when the situation reverses and the pipe diameter becomes smaller than the flow meter’s measuring pipe, issues arise: not only does the flow reading show significant noise, but the minimum measurable flow rate increases. How can we correct these errors using scientific methods and restore accurate measurements? This article will explain the solutions in detail.

Impact of Smaller Pipe Diameter on Flow Meter Measurements

In practice, it is rare for the pipe diameter to perfectly match the measurement pipe diameter of the vortex flow meter. This issue is particularly common when using imported vortex flow meters or products made with foreign technology. Due to differences in the outer diameter standards of seamless steel pipes, discrepancies in the inner diameter often occur. For instance, a 6-inch nominal diameter pipe in foreign standards has an outer diameter of 168 mm, while domestic standards have a size of 159 mm—quite a significant difference. Additionally, even with the same nominal diameter, pipes with different wall thicknesses can result in noticeable variations in inner diameter, further complicating the issue of matching the pipe diameter.

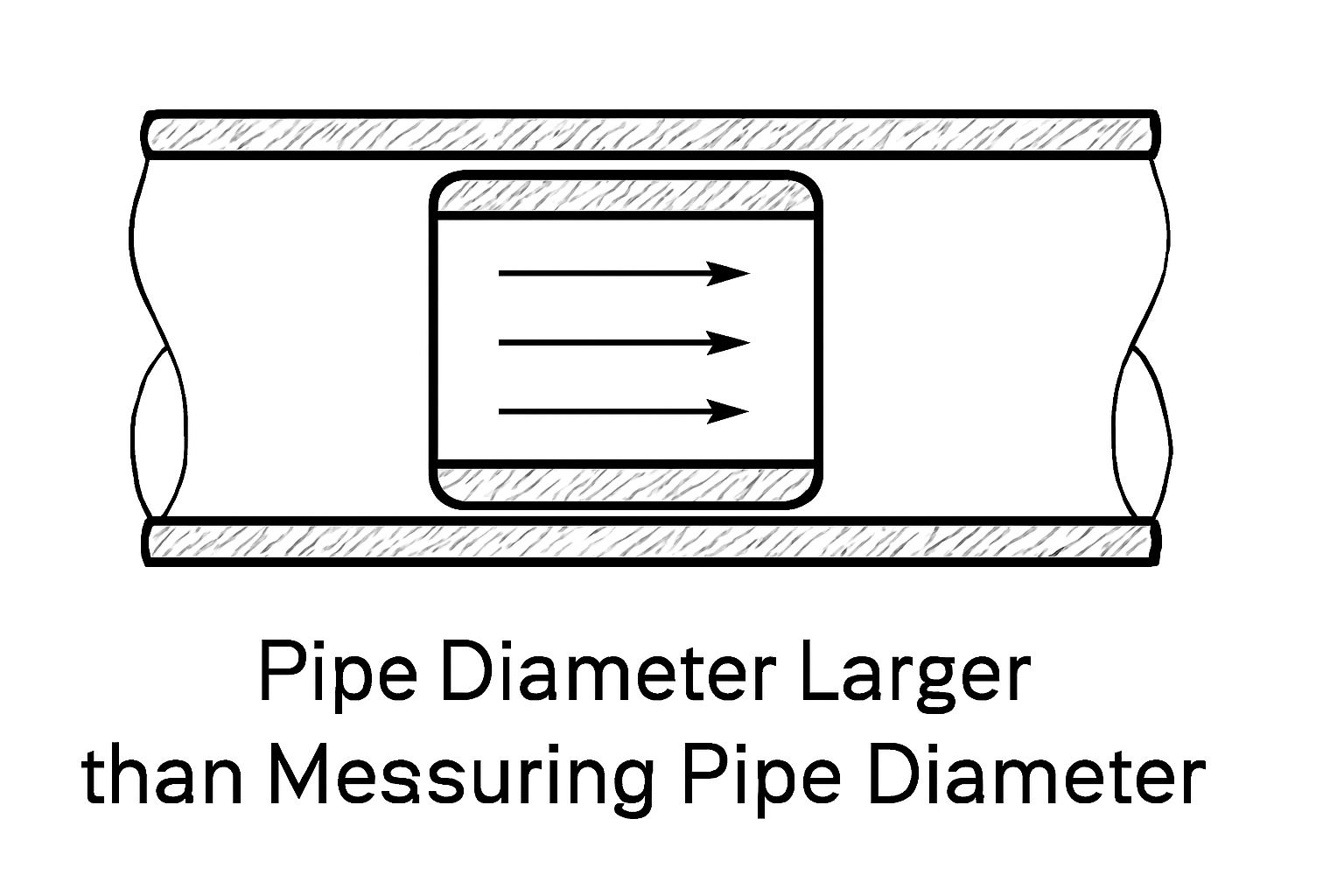

When the Pipe Diameter is Larger than the Measurement Pipe Diameter

During flow calibration, when the pipe diameter is equal to or slightly larger than the measuring pipe diameter of the vortex flow meter, the flow readings remain stable and the flow coefficient is normal. Although secondary flows occur when fluid passes through a step, the parts affected by the secondary flow lie outside the measuring pipe, meaning the impact on the instrument is negligible.

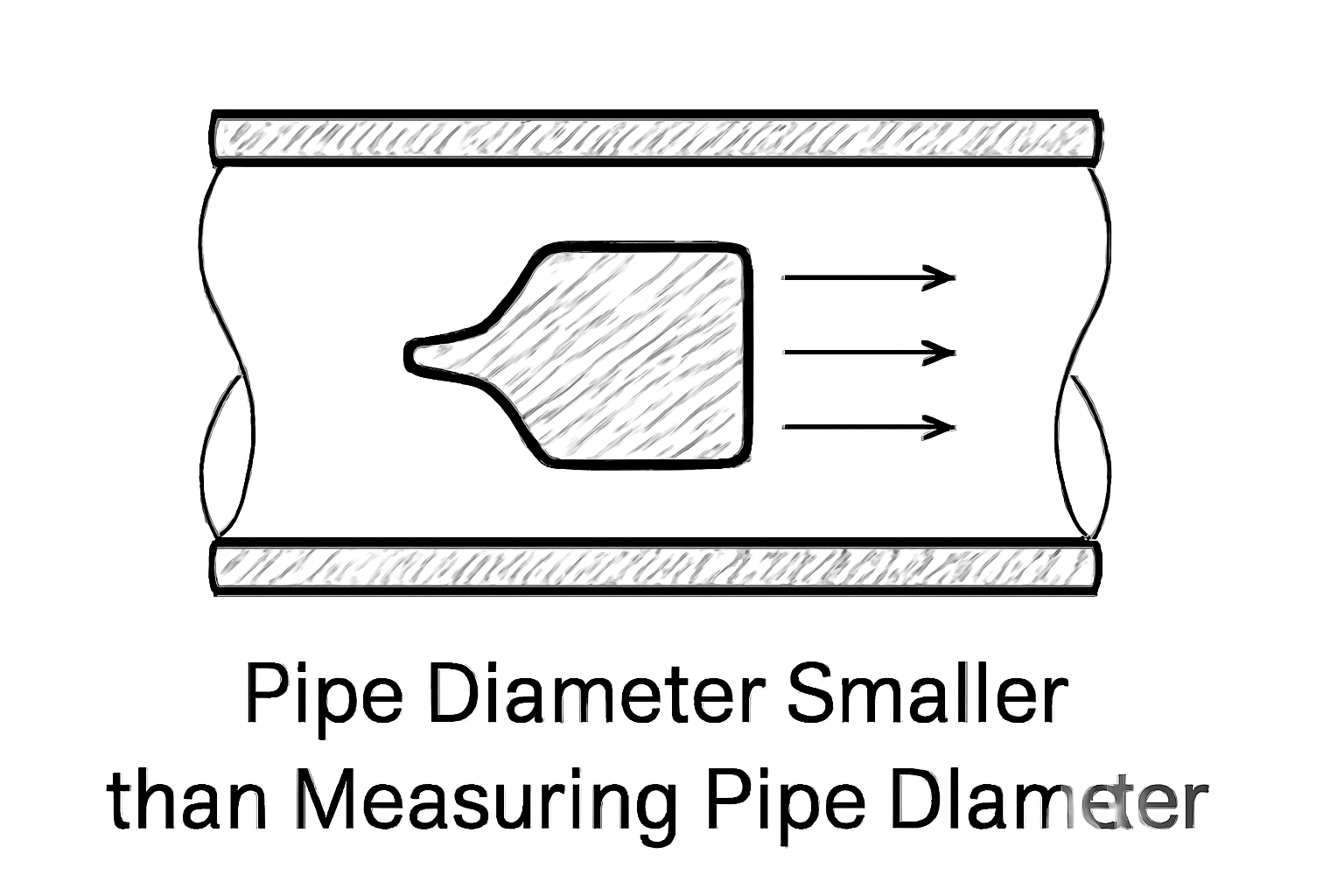

When the Pipe Diameter is Smaller than the Measurement Pipe Diameter

When the pipe diameter is smaller than the measuring pipe diameter (within 3%), the fluid passes through the larger measuring pipe at a high velocity. Due to the fluid’s inertia, the flow stream doesn’t have time to expand and strikes the measurement body, resulting in higher flow readings.

The error caused by a smaller pipe diameter can be compensated by adjusting the flow coefficient (Km). The correction factor FD is expressed as follows:

Where:

is the actual inner diameter of the measurement pipe

is the actual inner diameter of the pipe

The corrected flow coefficient

becomes:

This correction accounts for the fact that the fluid cannot immediately expand as it flows through the measuring pipe due to the high velocity and inertia of the fluid.

Consequences of a Smaller Pipe Diameter

In addition to the higher flow readings, a smaller pipe diameter also increases the minimum measurable flow rate, as vortex flow meters are typically installed with a constricted section.