1. Introduction

Wear-resistant ball valves serve as critical control points in industrial fluid transportation systems. Once failure occurs, even minor issues may cause media leakage, while severe cases can lead to equipment seizure, production downtime, and costly repairs.

This document analyzes common failure modes of wear-resistant ball valves, identifies underlying causes, and proposes preventive measures. The objective is to shift the focus from reactive maintenance to preventive quality control.

2. Common Failure Modes

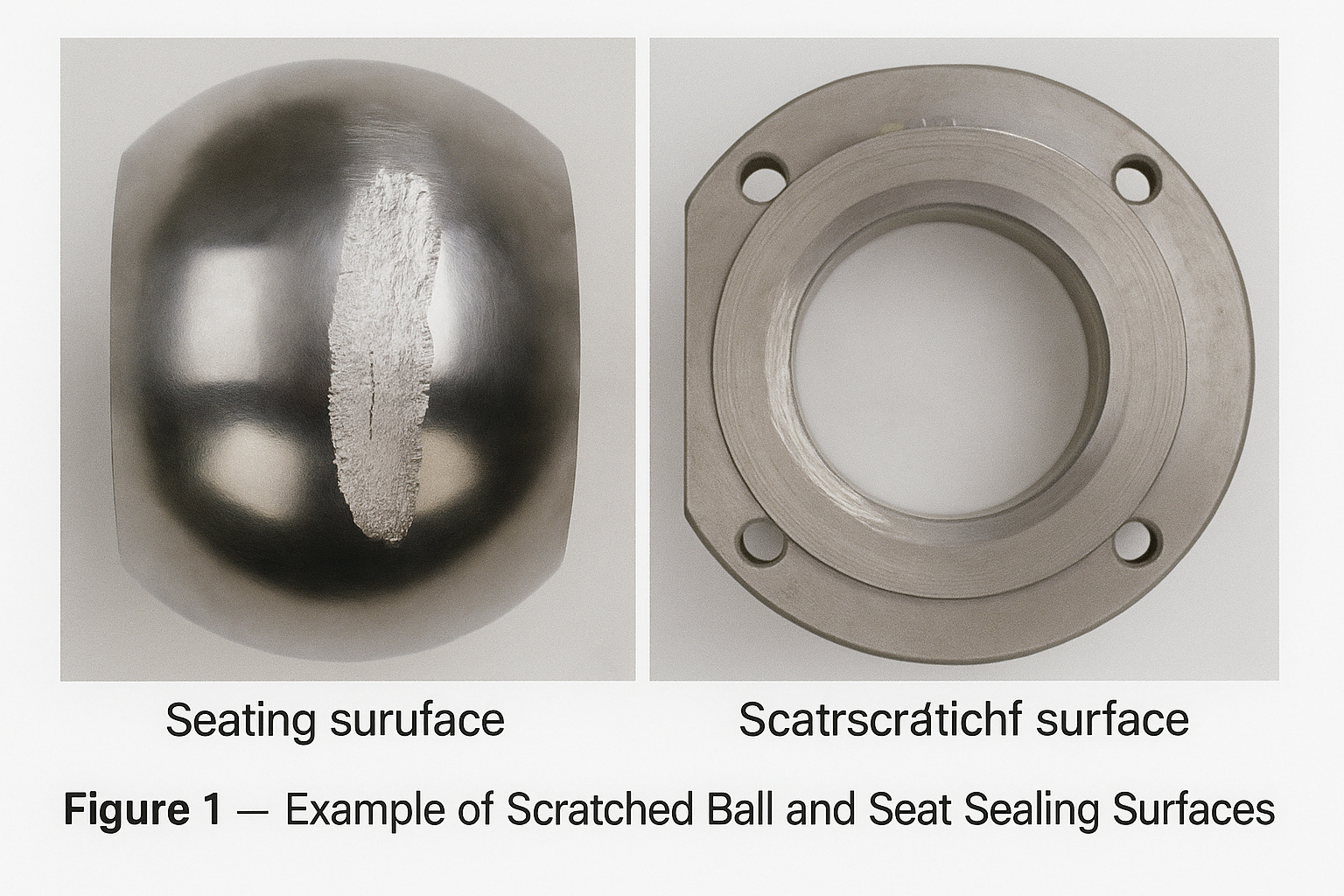

2.1 Scratched Sealing Surfaces

Root Causes: Inadequate surface hardening, low coating hardness, or particle impact.

Consequences: Leakage due to surface damage.

Solutions:

Optimize hardening process and powder composition.

Use scraper-type sealing structures to reduce media accumulation.

2.2 Coating Delamination

Root Causes: Poor bonding strength or insufficient corrosion resistance.

Solutions:

Improve surface treatment and spraying quality.

Enhance powder formulation to improve anti-corrosion capability.

2.3 Contamination in Spring Cavity

Root Causes: Inadequate cavity protection, oil or solids entering spring chamber.

Solutions:

Apply sealed spring cavity design.

Use disc springs for small-diameter valves in heavy oil/solid particle service.

2.4 External Leakage

Root Causes: Improper stem sealing design or low-quality packing material.

Solutions:

Use multiple low-emission composite packing systems.

Adopt high-performance certified packing materials.

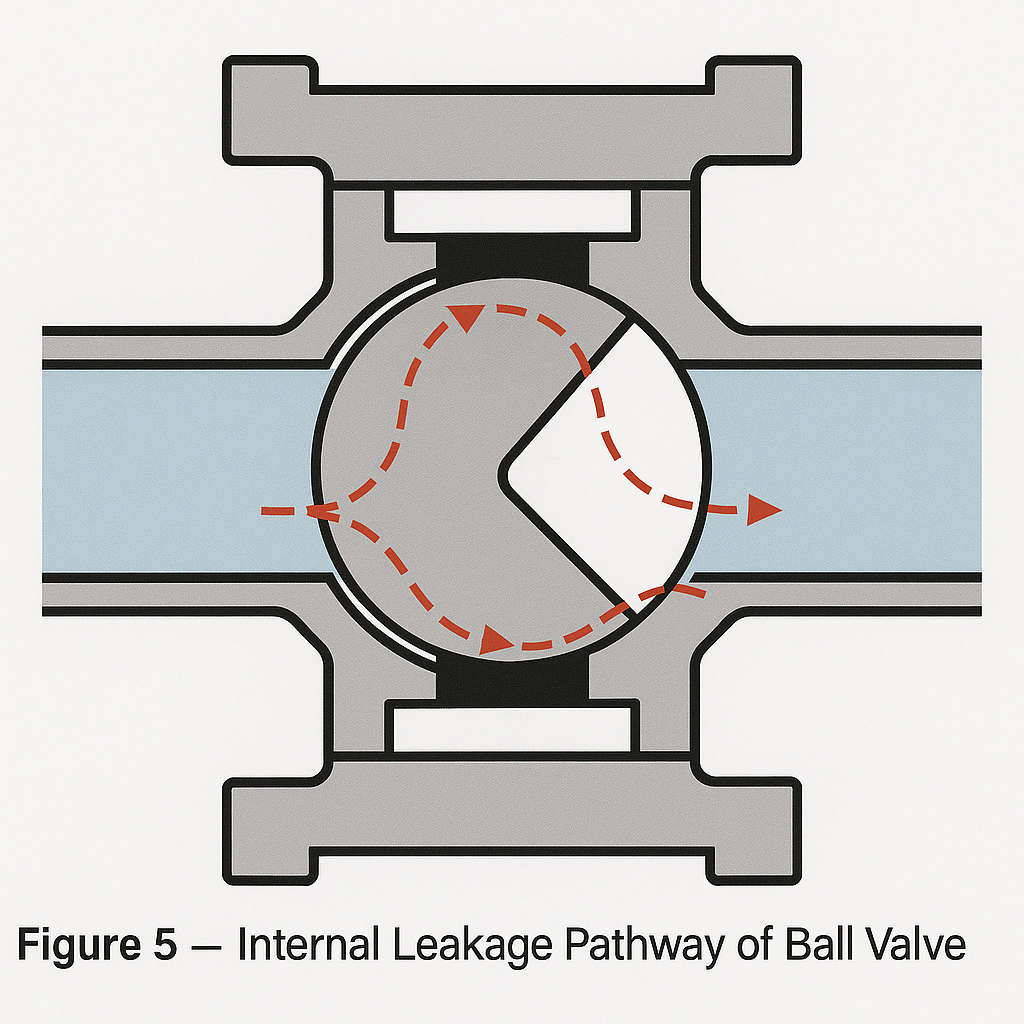

2.5 Internal Leakage

Root Causes: Scratched ball/seat surfaces, or failed seat cavity seals.

Solutions:

Improve surface hardening and coating quality.

Use scraper-type sealing design.

Adopt sealed spring cavity to prevent seal failure.

Enhance machining precision of critical parts.

2.6 Sticking or Blocked Operation

Root Causes: Media accumulation in body cavity, seat gaps, spring chamber, or stem-bearing clearance; inadequate actuator torque.

Solutions:

Optimize design and machining accuracy.

Improve coating quality.

Select actuators with appropriate torque output.

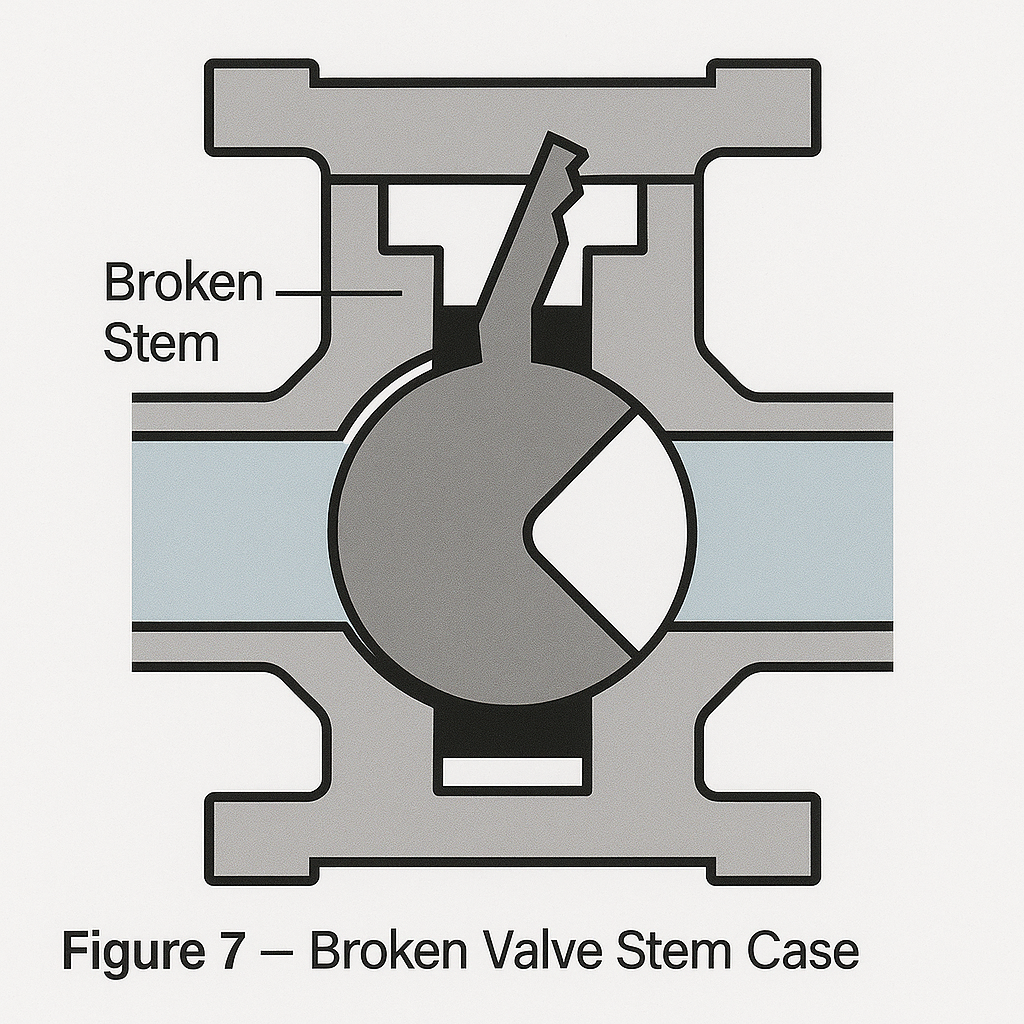

2.7 Stem Fracture

Root Causes: Undersized stem diameter, insufficient strength and rigidity.

Solutions:

Increase stem diameter.

Use higher-strength materials.

Improve machining and assembly precision.

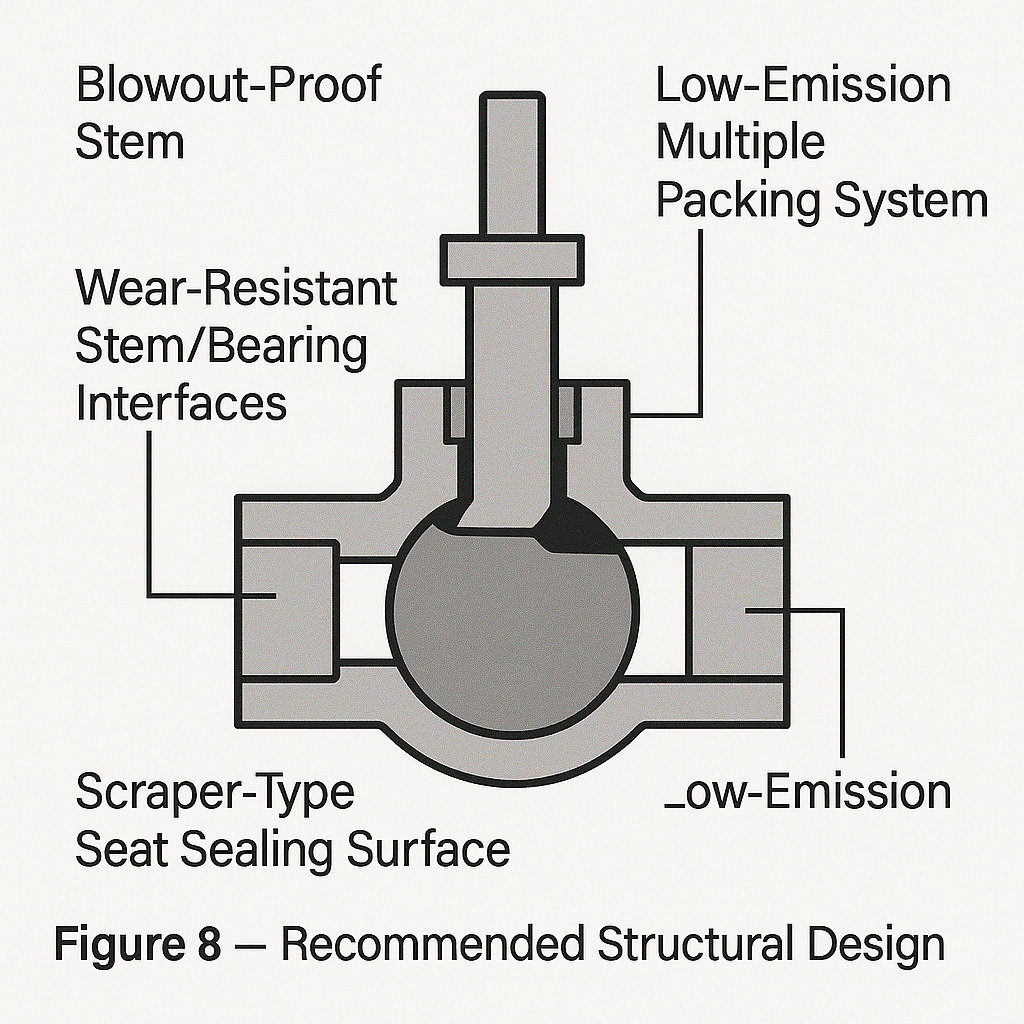

3. Key Quality Control Measures

3.1 Structural Design

Sealed spring cavity (dust-proof design).

Scraper-type seat sealing surface.

Wear-resistant stem/bearing interfaces.

Blowout-proof stem design.

Low-emission multiple packing systems.

3.2 Machining Precision of Critical Parts

Symmetry & Verticality: Drive slot accuracy to prevent eccentric torque.

Roundness: Ball and seat sealing roundness must meet precision requirements.

Surface Roughness: ≤ Ra0.2 (ball/seat), ≤ Ra0.4 (stem).

Seat Concentricity: ≤ 0.05 mm for cryogenic valves to ensure bi-directional sealing.

3.3 Surface Hardening Treatments

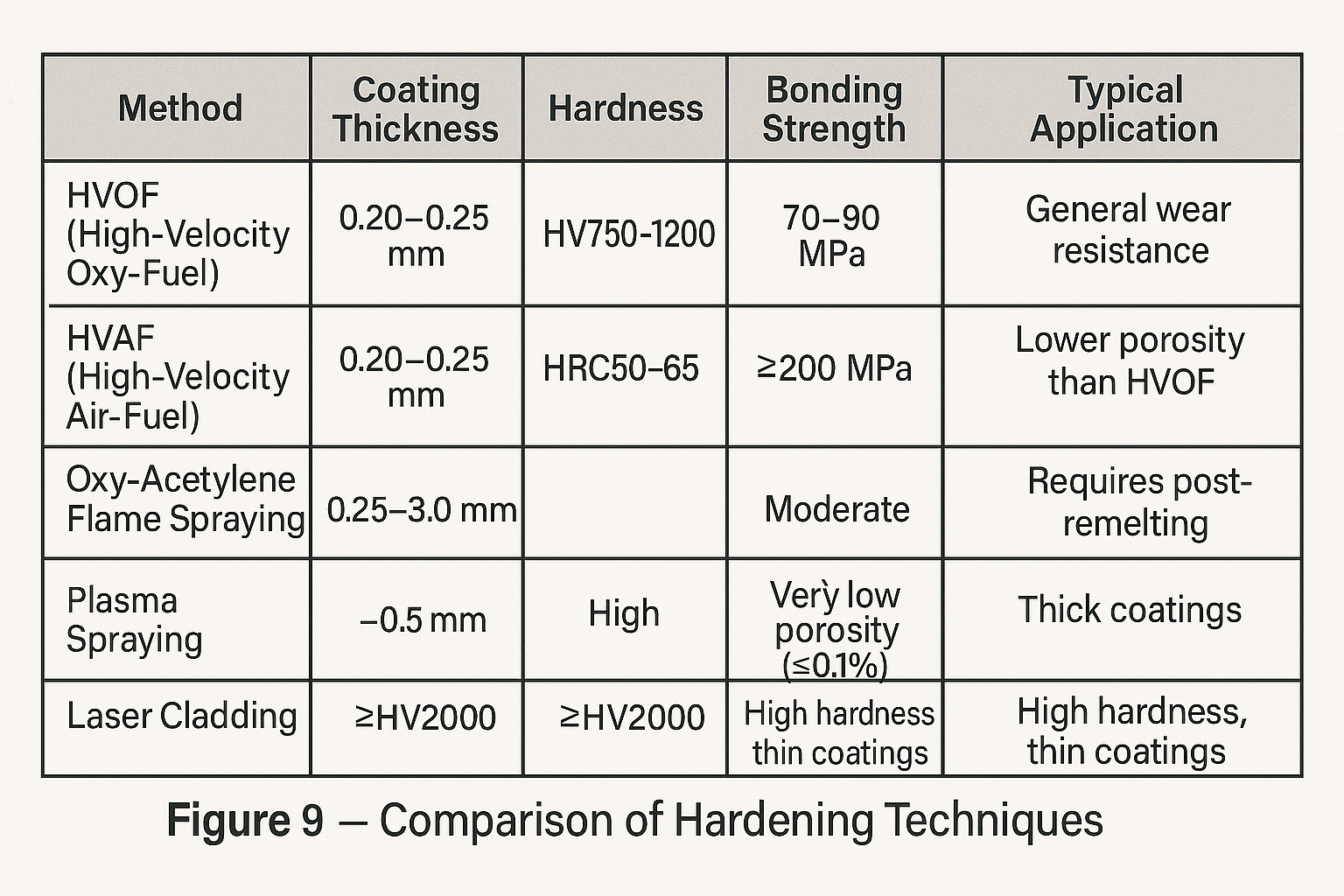

Different components require tailored hardening methods:

| Method | Coating Thickness | Hardness | Bonding Strength | Typical Application |

|---|---|---|---|---|

| HVOF (High-Velocity Oxy-Fuel) | 0.20–0.25 mm | HV750–1200 | 70–90 MPa | General wear resistance |

| HVAF (High-Velocity Air-Fuel) | 0.20–0.25 mm | HV750–1200 | 70–90 MPa | Lower porosity than HVOF |

| Oxy-Acetylene Flame Spraying | 0.5–0.7 mm | HRC50–65 | ≥200 MPa | Requires post-remelting |

| Plasma Spraying | 0.25–3.0 mm | HV700–1000 | Moderate | Thick coatings |

| Laser Cladding | ~0.5 mm | High | Very low porosity (≤0.1%) | High-strength sealing surfaces |

| CVD/PVD | 2–5 μm | ≥HV2000 | Thin layer | High hardness, thin coatings |

4. Conclusion

Premature failure of wear-resistant ball valves cannot be attributed to sealing issues alone. Instead, it results from a combination of design, machining accuracy, material properties, surface treatments, and application-specific conditions.

By implementing systematic quality control—from structural design and precision machining to advanced surface hardening technologies—manufacturers and end-users can significantly improve valve reliability, reduce downtime, and extend service life.