The functioning of a thermocouple relies on the thermoelectric potential, which depends not only on the temperature of the measurement junction but also on the temperature of the reference junction. In practical applications, the reference junction is commonly referred to as the “cold junction.”

For a given thermocouple, when the reference junction temperature remains constant, the overall thermoelectric potential becomes a single-valued function of the measurement junction’s temperature. That is, a specific thermoelectric potential corresponds to a specific temperature. However, in thermocouple tables, the reference junction temperature is assumed to be zero. In real-world applications, the temperature of the reference junction can vary significantly, making it impossible to maintain it at zero degrees Celsius. This temperature variation introduces measurement errors, and thus, cold-junction compensation is necessary to ensure the accuracy of the temperature measurement.

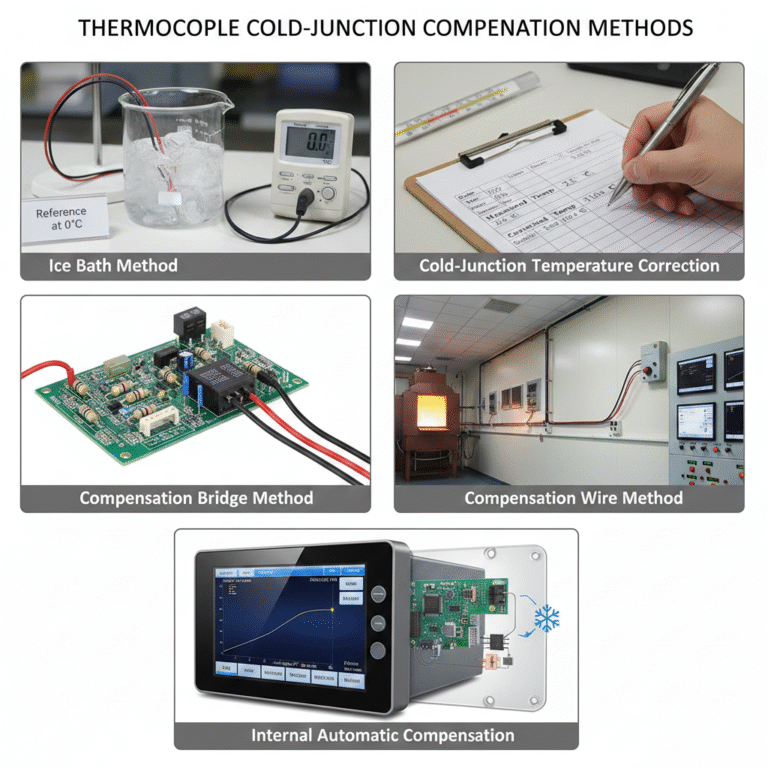

Common Methods for Cold-Junction Temperature Compensation

Ice Bath Method

Overview: This method is commonly used in laboratory settings, where the reference junction is kept at a constant 0°C by immersing it in an ice bath.

Advantages: Provides a precise, stable reference temperature.

Disadvantages: It is costly and difficult to maintain, making it impractical for most industrial applications.

Cold-Junction Temperature Correction

Overview: In applications where the reference junction temperature cannot be maintained at 0°C, the instrument’s reading is corrected manually based on the cold junction’s actual temperature.

Advantages: Easy to implement in simpler systems.

Disadvantages: This method introduces a significant amount of error and is less reliable than others.

Compensation Bridge Method

Overview: This method uses an unbalanced electrical bridge to generate an electrical potential that compensates for changes in the cold junction temperature. Compensation bridges are usually standalone devices.

Advantages: Effective for precise temperature compensation in certain applications.

Disadvantages: It is rarely used independently and often requires additional equipment.

Compensation Wire Method

Overview: The most common method involves extending the thermocouple with compensation wire to a location with a more stable temperature (usually a control room). The cold junction is then adjusted manually to compensate for temperature variations.

Advantages: Cost-effective and simple to implement.

Disadvantages: For high-end precious-metal thermocouples, extending the wire may not be feasible due to the high cost. In such cases, wires made from cheaper metals with similar thermoelectric properties are used instead.

Internal Automatic Compensation in Display Instruments

Overview: Modern display instruments, such as micro-color recorders, electronic potentiometers, and DCS (Distributed Control System) boards, automatically compensate for cold junction temperature variations. These systems use methods like copper resistance compensation, compensation bridges, or the use of transistor junctions that vary with temperature.

Advantages: Provides automatic, seamless compensation with minimal user input, reducing the risk of human error.

Disadvantages: The complexity of the internal circuitry may add to the cost of the instrument.