1. Differences in Application Requirements

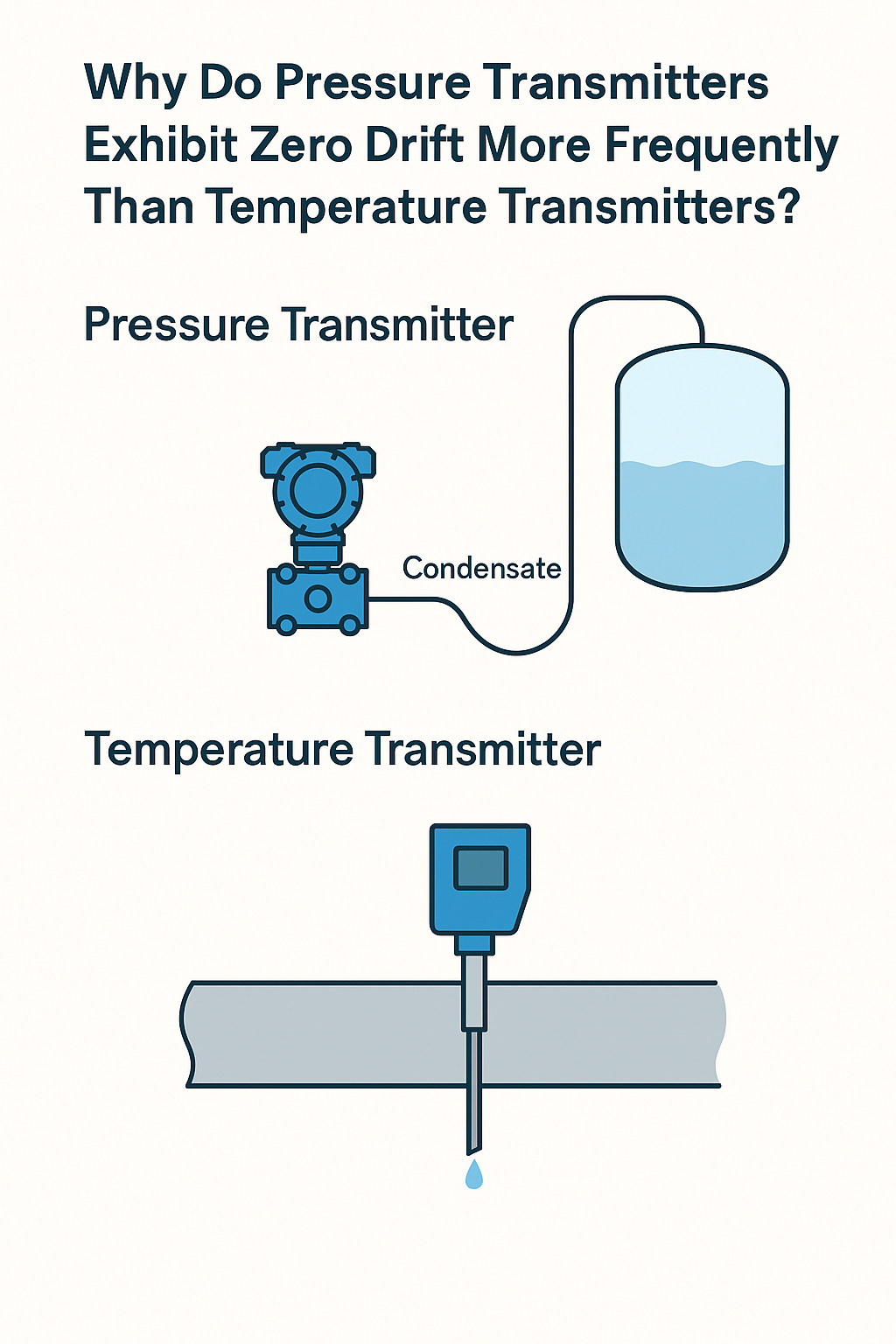

Pressure transmitters—especially differential pressure transmitters—often require range adjustments based on specific field conditions. For example, when used for level measurement in sealed tanks, condensation of the gas-phase medium can cause condensate to accumulate in the impulse lines or low-pressure chambers. This creates an unintended static pressure, resulting in output deviation. To compensate, a zero suppression or negative zero shift is applied, moving the transmitter’s zero point to reflect this starting bias.

In contrast, temperature transmitters generally do not face such variable process conditions. The measurement environment for temperature is more stable and typically doesn’t involve media that accumulate or introduce static interference into the measurement.

2. Structural and Installation Differences

Pressure transmitters are often installed below the tapping point, causing condensate or water to accumulate in the impulse tubing. The resulting hydrostatic head adds an additional pressure component to the true process value, which must be accounted for by adjusting the transmitter’s zero.

Temperature transmitters, on the other hand, are commonly mounted directly into the process piping or thermowell. Their installation rarely introduces similar external influences that would necessitate a zero offset.

3. Measurement Principle

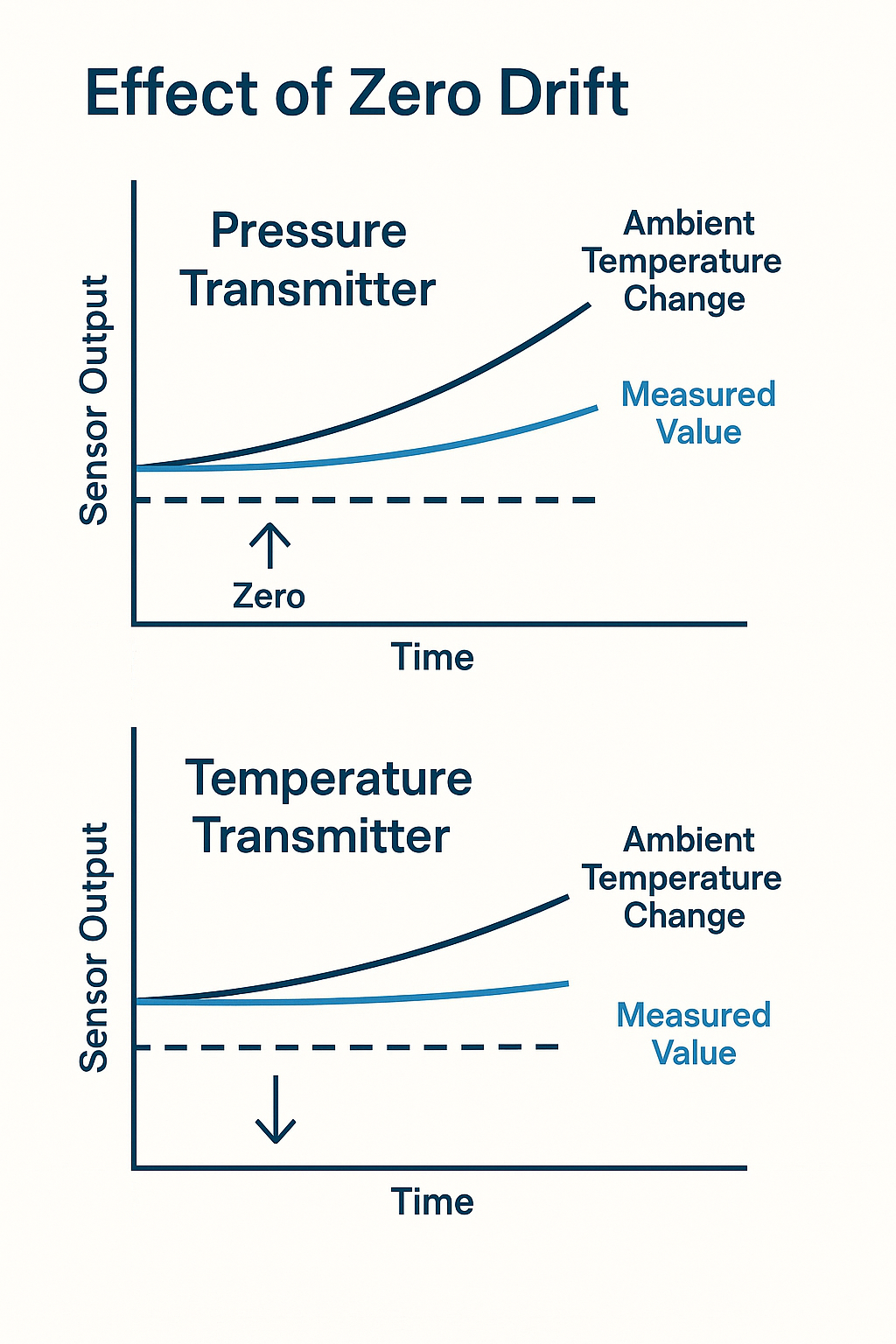

Pressure transmitters function based on mechanical deformation or strain under applied pressure. As such, they are highly sensitive to installation height, orientation, fluid column pressure, and even the density of the media. These factors can cause systematic errors unless compensated by zero drift correction.

Temperature transmitters typically use RTDs or thermocouples, based on the principle of thermoelectric voltage or resistance change. These signals correlate directly with temperature, and are less affected by installation-related influences. Consequently, the concept of zero drift is largely irrelevant in temperature measurements.

4. Technical Constraints

Certain types of pressure transmitters—such as differential models with square root extraction (used for flow measurement)—cannot implement zero suppression easily due to their internal calculation algorithms. These limitations may restrict the capability to adjust for environmental biases, increasing the risk of persistent zero drift.

Temperature transmitters, due to their simpler measurement mechanisms, generally do not require such complex compensation strategies and rarely experience meaningful drift in baseline readings under normal conditions.

5. Summary and Recommendations

| Aspect | Pressure Transmitters | Temperature Transmitters |

|---|---|---|

| Need for zero drift compensation | Frequent, especially in liquid level and flow applications | Rare |

| Affected by installation and media | Yes (height, condensation, media density) | Minimal |

| Zero adjustment required | Often necessary | Generally unnecessary |

| Technical workarounds | Zero suppression, remote seal, diaphragm fill fluid | Calibration only |

Recommendations to Minimize Pressure Transmitter Zero Drift:

Use impulse line with condensate traps or remote diaphragm seals

Ensure correct elevation and mounting orientation

Regularly vent or drain condensate

Select transmitters with built-in zero drift compensation features