1. Introduction

In demanding industrial environments—characterized by high temperature, high pressure, strong corrosiveness, or crystallizing media—diaphragm-sealed pressure transmitters act as a critical safety and accuracy barrier. However, many users face performance failures due to subtle but crucial configuration issues, such as:

Fill fluid solidifying in cold climates;

Excessive capillary length causing slow response;

Improper selection of diaphragm materials for corrosive or high-temperature media.

This article examines these common issues and offers practical guidance to ensure stable and accurate measurement, even under extreme operating conditions.

2. Reference Standards: Key Design Limits

According to SH/T 3005-2016, the following specifications apply when using remote diaphragm seals:

Capillaries must be stainless steel (316SS); armored sheath is preferably a 300-series SS;

Total length should not exceed 15 meters;

Minimum diaphragm material is 316LSS;

Fill fluid must be selected based on:

Process and ambient temperature range;

Capillary length and internal diameter;

Viscosity and thermal expansion properties.

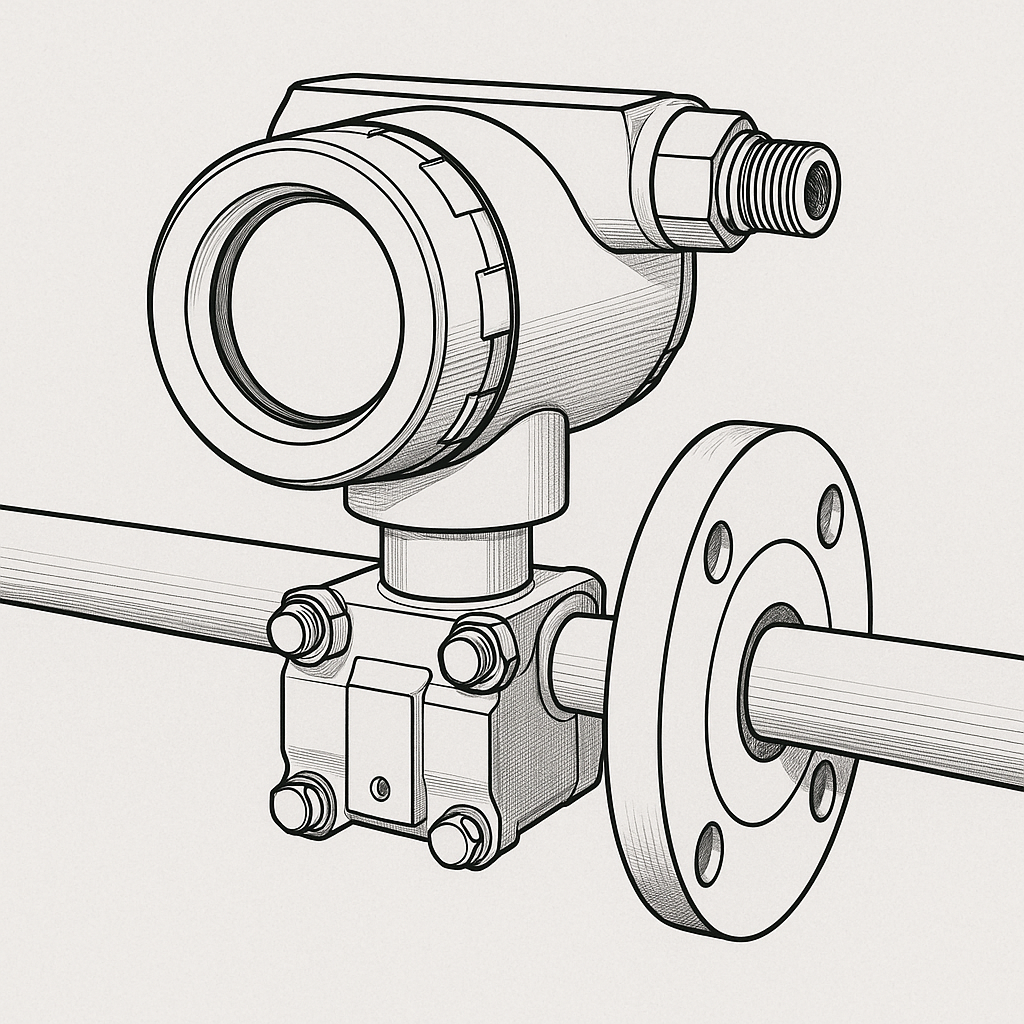

3. Common Application Scenarios

| Application | Typical Instrument |

|---|---|

| Crude oil pressure | Diaphragm pressure transmitter |

| Residual oil flow | Wedge element + dual-flange DP transmitter |

| Tank level | Dual-flange diaphragm DP transmitter |

4. Key Factors Behind Failure

4.1 Diaphragm Material Incompatibility

Minimum requirement: 316L stainless steel.

For harsh media (e.g., hydrogen at high temperatures): surface gold plating is recommended.

📌 Incorrect material selection can lead to corrosion, rupture, or zero drift.

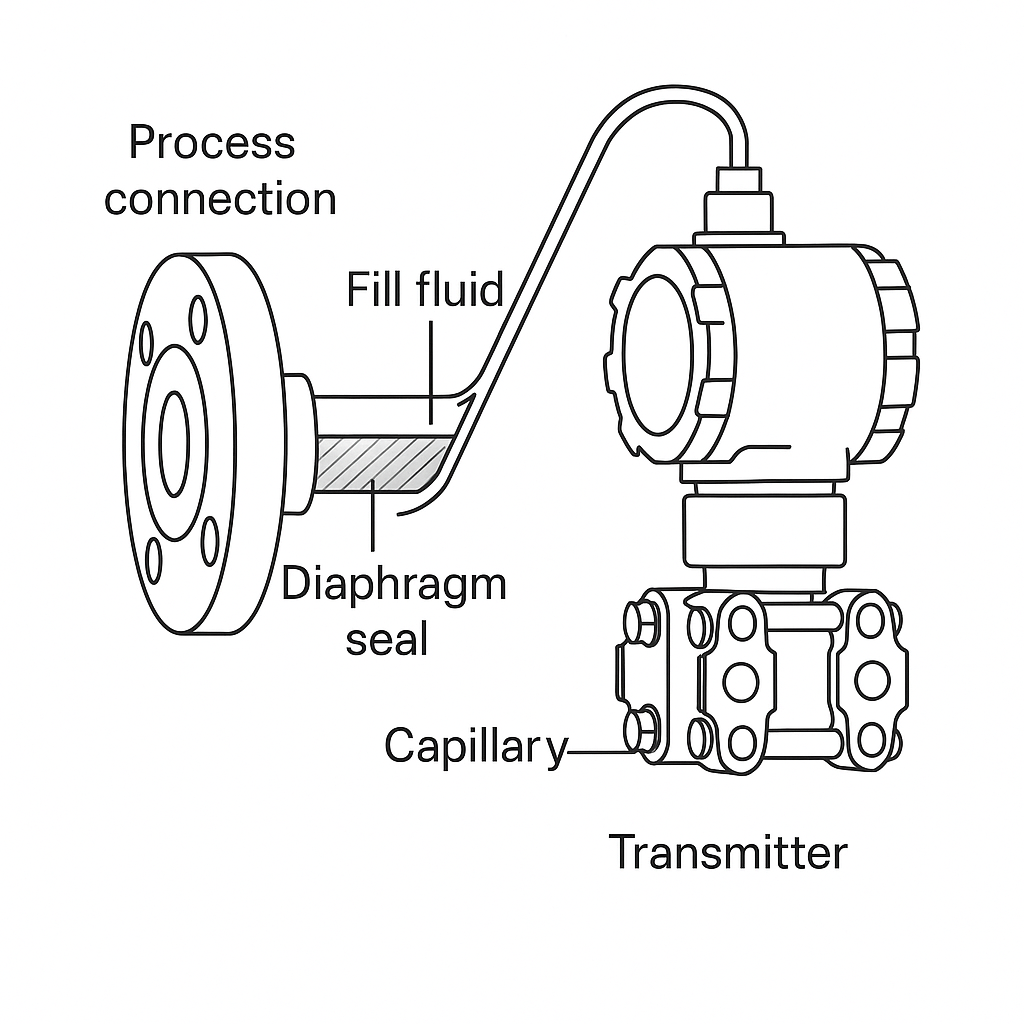

4.2 Fill Fluid Incompatibility

Different fill fluids have different operating temperature and pressure ranges. Choosing an inappropriate fluid may lead to:

Solidification in cold weather;

Thermal expansion errors in hot environments;

Delayed response due to high viscosity.

🔹 Fill Fluid Property Comparison

| Fill Fluid | Temp. Range (°C) | Viscosity (cSt @25°C) | Thermal Expansion (10⁻³/°C) |

|---|---|---|---|

| DC200 | -45 ~ +205 | 0.93 | 0.0095 |

| DC704 | 0 ~ +315 | 1.07 | 0.0440 |

| HEROL | -45 ~ +175 | 1.85 | 0.0065 |

| Syltherm® XLT | -75 ~ +150 | 0.85 | 0.0016 |

| Neobee M-20 | -15 ~ +120 | 0.92 | 0.0080 |

Recommendation: Use low-viscosity, low-expansion fluids for faster response and reduced error under temperature variation.

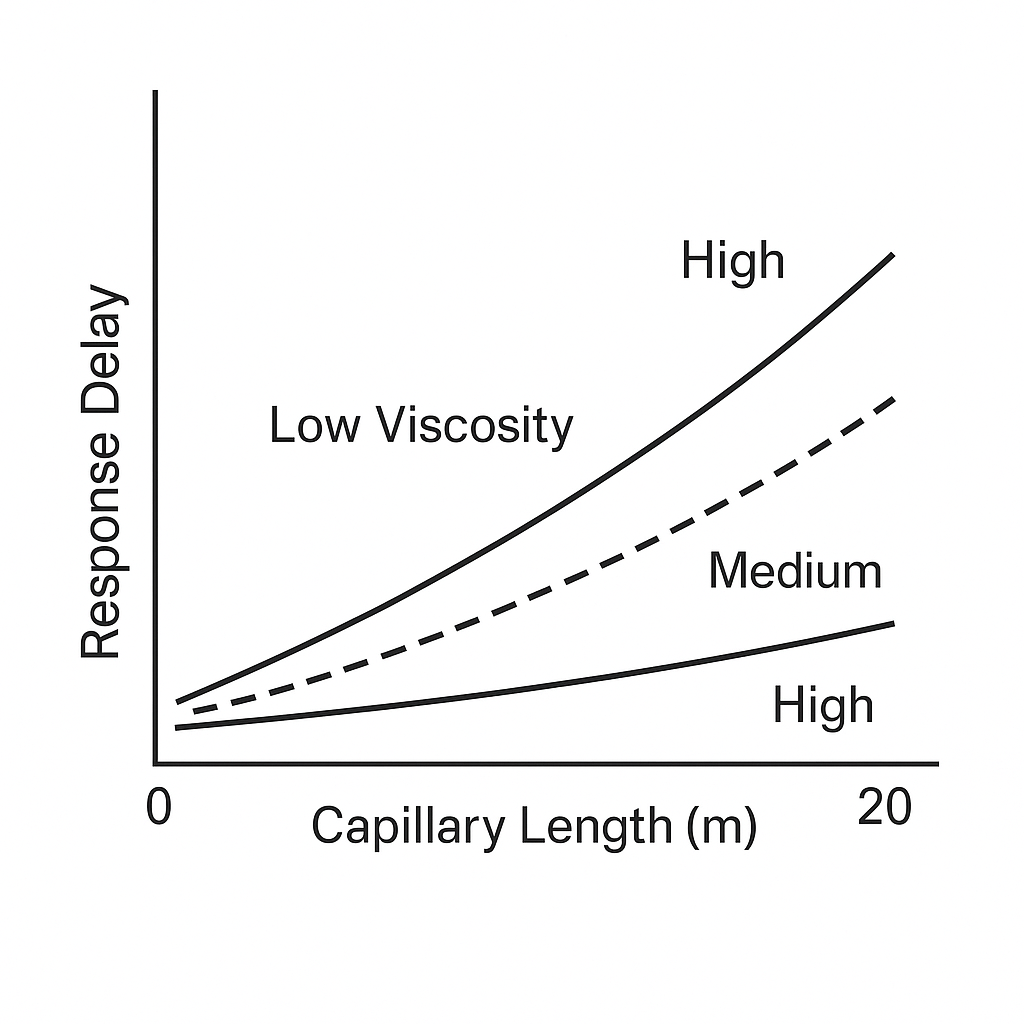

4.3 Capillary Design: Length and Diameter

The capillary parameters directly impact the response time of the transmitter.

📈 Impact Summary:

| Parameter | Effect on Response Time |

|---|---|

| Longer capillary | Increases pressure delay |

| Smaller inner diameter | Increases resistance to pressure |

| More viscous fluid | Slower response |

In small tanks or fast-changing levels, capillary delay can severely affect measurement accuracy.

5. Application Tips and Hidden Risks

Larger diaphragm sizes (e.g., DN80 or DN100) provide better accuracy than DN50 in most installations.

Lower-stiffness diaphragms improve sensitivity and resolution.

Pay attention to fluid viscosity and thermal expansion coefficient, not just temperature range.

In dual-capillary DP transmitters:

Use same length, same ID, same fill fluid for both capillaries.

This helps cancel out environmental temperature effects.

Be aware of hydrostatic head effects between top and bottom flanges:

Temperature shifts cause fill fluid density to change.

This leads to zero drift, especially in cold climates.

Mitigation: In regions with large seasonal temperature differences, apply heat tracing and thermal insulation to capillaries.

6. Conclusion

To ensure reliable measurement under harsh conditions, proper configuration of diaphragm pressure transmitters is essential. Key areas of focus include:

Choosing the correct diaphragm material based on process media;

Selecting appropriate fill fluids considering both temperature range and viscosity;

Designing capillary systems with balanced length and minimal delay.

A systematic approach to these three areas can significantly reduce errors, prevent downtime, and extend instrument life in critical process applications.