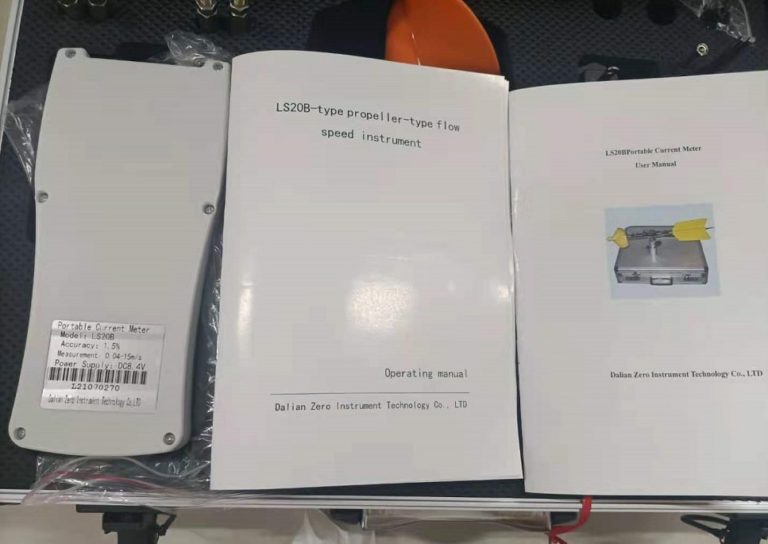

Scope: open-channel/current meters, insertion velocity probes, electromagnetic/ultrasonic velocity sensors used in water resources, environmental monitoring, and industrial processes.

1) Why calibration is essential

Eliminates drift: Sensors age; electronics drift; mechanical parts wear; ambient conditions change. Calibration removes systematic error so readings remain traceable to national/industry standards.

Protects decisions: Discharge calculations, compliance reports, and control loops all rely on velocity accuracy; bad data = wrong flow, wrong dosing, wrong alarms.

Meets audits & contracts: Many QA programs (ISO/IEC 17025–based systems, project specs) require documented, periodic calibration and as-found/as-left data.

Reduces lifecycle cost: Early detection of bias prevents mis-operation, re-sampling, and penalties.

Target performance indicators: zero offset, span error, linearity, repeatability, response time, and environmental stability (temperature/humidity).

2) Typical calibration & verification methods

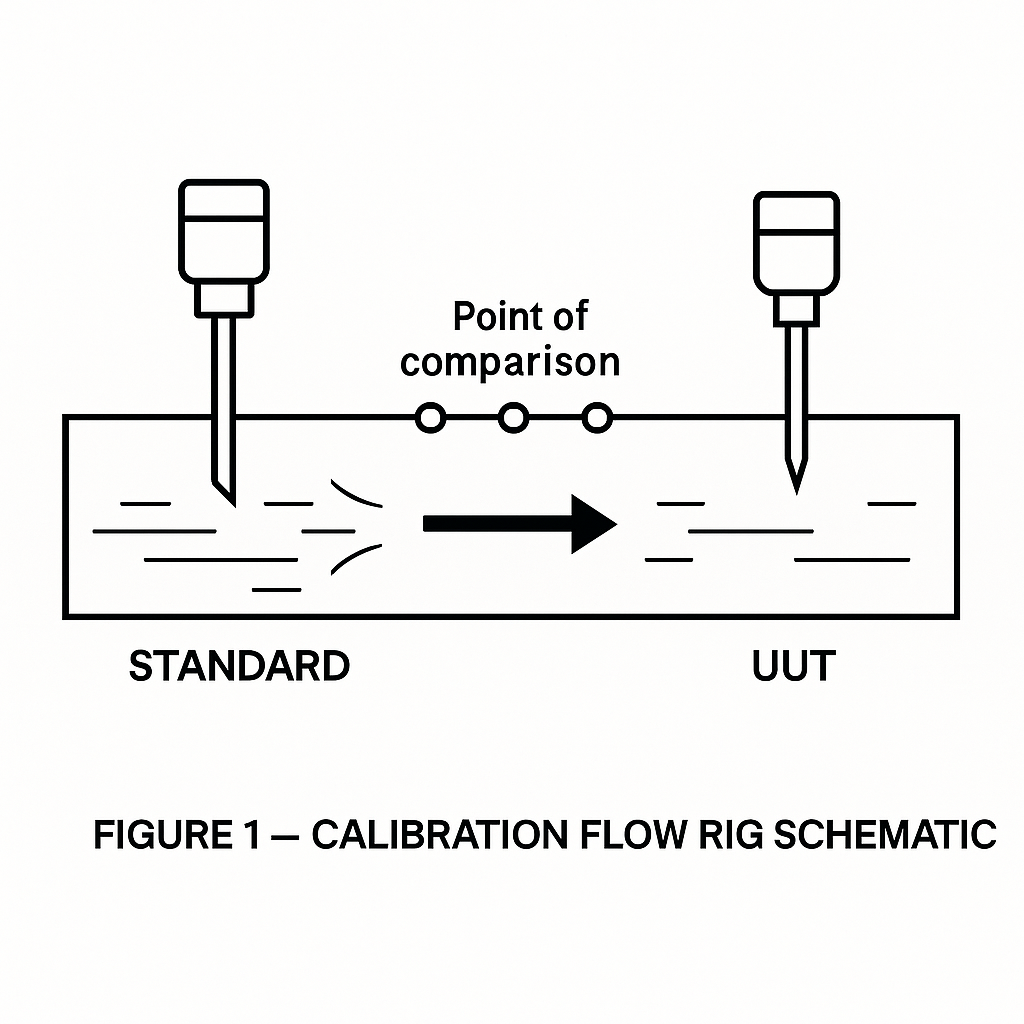

Laboratory calibration on a standard rig

Compare the unit under test (UUT) against a traceable standard in a controlled flow facility for multiple points across the range. Highest accuracy; requires dedicated equipment.On-site side-by-side comparison

Run a certified portable reference velocity meter simultaneously with the UUT in the same profile/section. Ideal for large/installed systems that can’t be removed.Sensor characterization tests

Check sensitivity, linearity, repeatability, and zero in fixtures; confirm response time under step changes.Electronics/IO verification

Stimulate the signal chain; verify acquisition, processing, display, and outputs (4–20 mA, pulse, RS-485) for accuracy and stability.

Recommended calibration point set (example)

Zero → 10% → 25% → 50% → 75% → 90% → 100% of full scale (both upscale and downscale to capture hysteresis).

3) What to include in a complete calibration

Zero (offset) calibration

Span (range) calibration

Linearity test (full-range multi-point)

Repeatability test (≥3 repeats at 3–5 points)

Response time test (10–90% or T63)

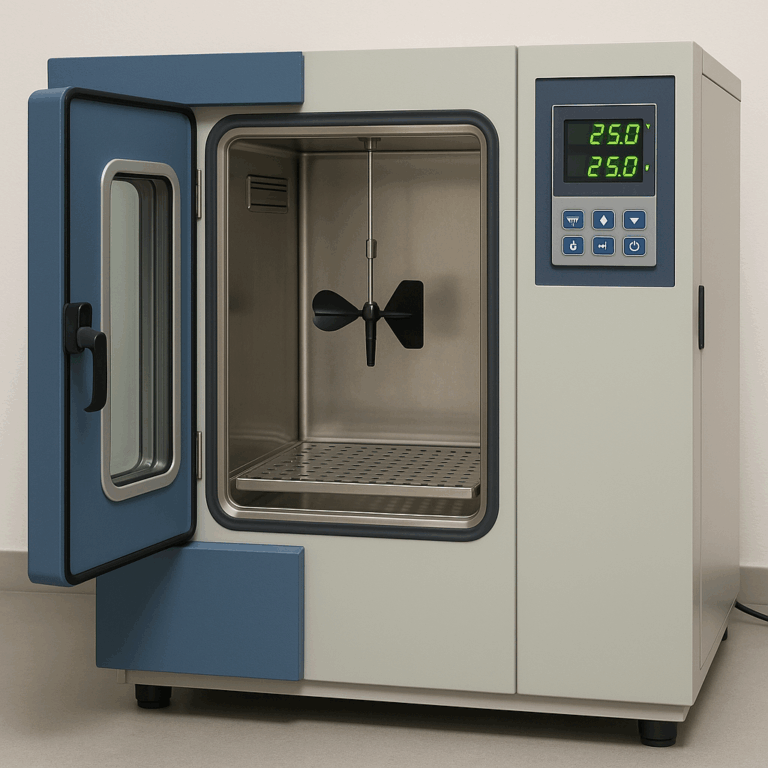

Environmental checks (temperature/humidity influence if applicable)

4) Calibration interval (how often?)

General rule: every 6–12 months, adjusted by use frequency, criticality, and environment.

Recalibrate immediately if:

The instrument was repaired or adjusted;

Abnormal readings appear or QA flags a data shift;

The unit experienced shock/rough handling or harsh conditions.

5) Field checklist (quick pass/fail before sending to a lab)

Site condition stable (depth/profile not changing rapidly).

Sensor clean; no fouling/bubbles on transducers; cables intact.

Reference meter within its own calibration validity.

IO sanity check: 4–20 mA loop, pulse scaling, and RS-485 address/baud verified.

Record water temperature (affects some ultrasonic/electromagnetic measurements).

Log as-found data at all points before adjustments; then log as-left.

6) Documentation to keep (audit-ready)

Instrument ID, model/SN, firmware, location, medium.

Calibration date, due date, environmental conditions.

Method & standards used (traceability statement).

Tabulated as-found vs. as-left results (zero/span/linearity/repeatability/response).

Measurement uncertainty and pass/fail against acceptance limits.

Technician, lab accreditation (if applicable), and signatures.

Maintenance notes (cleaning, sealing, repairs).

Simple acceptance limits (example – edit to your spec)

| Item | Limit |

|---|---|

| Zero offset | ≤ ±0.5% of full scale |

| Span error | ≤ ±0.5% of reading |

| Linearity (BFSL) | ≤ ±0.5% of full scale |

| Repeatability | ≤ 0.2% of reading |

| Response time T63 | Within datasheet spec |

7) Common pitfalls (and how to avoid them)

Ignoring installation effects: swirl, uneven profiles, or entrained air bias readings—verify the measurement section or use profile compensation.

No as-found data: you lose evidence of drift and can’t assess process impact.

Reference uncertainty overlooked: your “standard” might be out of tolerance.

Environmental mismatch: lab calibration at 23 °C copied to a site at 3 °C without verifying temp influence.

Mini template — Calibration record (paste into your QA form)

Instrument: Velocity Meter, Model ___, S/N ___, Location ___

Medium/Condition: Water, Temp ___ °C, Profile note ___

Method: ☐ Lab standard rig ☐ On-site comparison ☐ Bench characterization

Standards: Ref. meter S/N ___ (Cal due ___), Traceability ___

Results:

Zero: ___ (Limit: ___) — Pass/Fail

Span @ points (%FS): 10 ___ / 25 ___ / 50 ___ / 75 ___ / 100 ___ (Limits: ___)

Linearity BFSL: ___ — Pass/Fail

Repeatability: ___ — Pass/Fail

Response time: ___ — Pass/Fail

Environmental influence (if tested): ___ — Pass/Fail

Adjustments made: ___

As-found data attached: ☐Yes ☐No

As-left data attached: ☐Yes ☐No

Tech/Lab: ___ / Accreditation ___

Next due date: ___