In industrial environments, the proper installation of cables—whether for power, control, instrumentation, or data—is vital for both short-term performance and long-term reliability. One of the most often overlooked yet critical aspects of cable installation is the minimum bend radius. Ignoring this factor can lead to cable damage, safety risks, and system malfunctions.

This article explores the technical reasons, risks, and industry standards behind bend radius requirements and offers best practices for ensuring compliance.

1. What Is Bend Radius?

The bend radius of a cable is the minimum radius one can bend the cable without causing mechanical damage or compromising its performance. It is typically expressed as a multiple of the cable’s outer diameter (OD).

For example, a cable with an OD of 10 mm and a specified bend radius of 10×OD should not be bent tighter than a 100 mm radius.

2. Why It Matters

2.1. Mechanical Protection

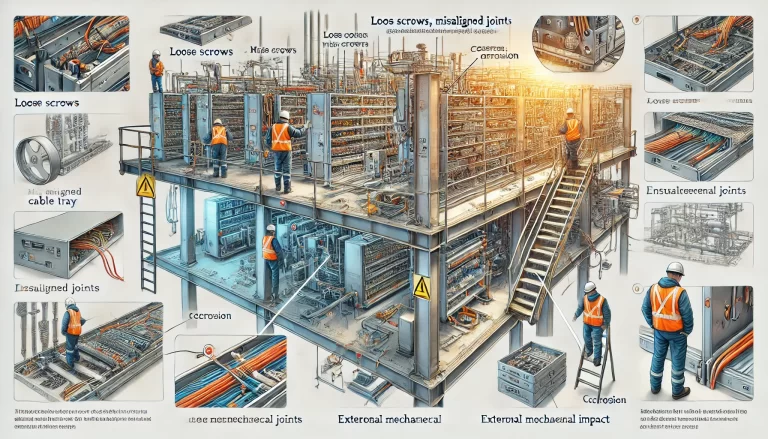

Cables are constructed with multiple layers—including conductors, insulation, shielding, and outer sheaths. Bending the cable beyond its rated radius can result in:

Conductor breakage (especially in multi-stranded cables)

Cracks in insulation, leading to reduced dielectric strength

Deformation of shield layers or armoring

Sheath compression or splitting

This damage may not be immediately visible but can lead to failure during operation.

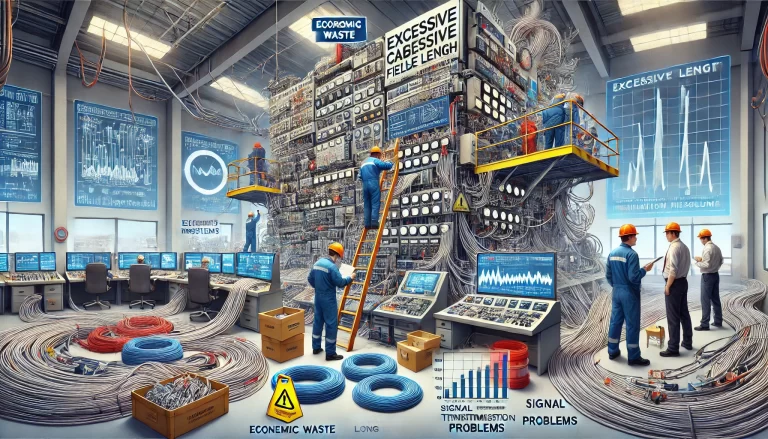

2.2. Electrical and Optical Performance

In both power and signal applications, tight bending can significantly affect performance:

For power cables, insulation breakdown can cause partial discharges, which over time lead to faults.

For data and control cables, improper bends can result in signal attenuation, crosstalk, and EMI issues.

For fiber optic cables, exceeding bend radius can cause light leakage, dramatically increasing optical loss and possibly resulting in data transmission failure.

2.3. Installation and Maintenance Reliability

Cables installed without respecting bend radius are prone to:

Mechanical fatigue, reducing lifespan

Difficulty during maintenance, as bent cables may not return to their original form

Violations of international standards, which may result in failed inspections or project rework

3. Typical Bend Radius Standards

Different cable types have varying bend radius requirements, often specified by international standards (such as IEC, IEEE, NEC) or manufacturer guidelines.

| Cable Type | Minimum Bend Radius |

|---|---|

| Non-armored power cable | 6 × cable OD |

| Armored cable | 12 × cable OD |

| Control cable | 6–10 × cable OD |

| Coaxial cable | Typically 10 × cable OD |

| Fiber optic cable | 10–20 × cable OD (depends on design) |

| Portable flexible cable | 6 × cable OD |

📌 Always consult the specific manufacturer’s datasheet for exact values.

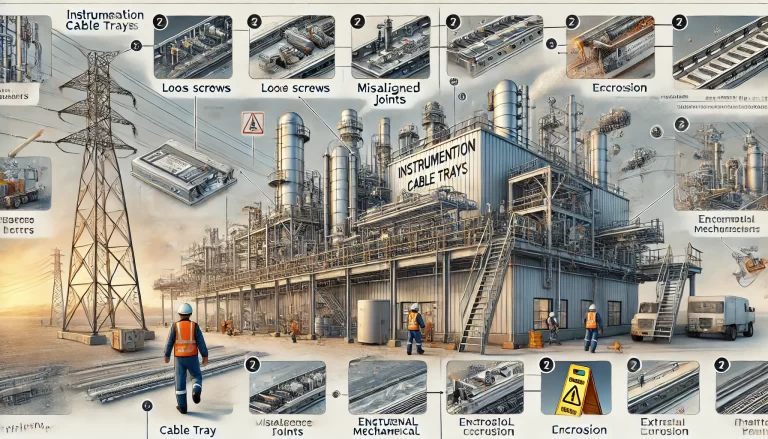

4. Best Practices for Cable Routing and Installation

To ensure safe and effective cable installation:

Use rollers and guides when routing cables to maintain minimum bend radius.

Avoid sharp corners—use wide cable trays or bend radii adapters.

Anchor cables properly to prevent movement-induced stress.

Educate installation teams on handling techniques, especially for fiber optics and armored cables.

Inspect installation bends during QA checks and verify against standards.

5. Consequences of Ignoring Bend Radius

| Violation | Potential Result |

|---|---|

| Overbending fiber optics | Severe signal loss, link failure |

| Tight bend in power cable | Insulation breakdown, fire risk |

| Bending armored cable tightly | Deformation, corrosion exposure |

| Long-term bent state | Permanent damage, reduced flexibility, hard spots |

6. Summary

Respecting the minimum bend radius during cable installation is more than a best practice—it’s a technical necessity. From protecting internal structures to ensuring long-term operational stability, bend radius limitations play a critical role across power, control, data, and communication systems.

Whether you’re wiring an automation system or installing a fiber optic network, adhering to bend radius guidelines helps prevent failure, reduce maintenance costs, and ensure compliance with international standards.